2507 duplex stainless steel, also known as UNS S32750 and W.Nr. 1.4410, is a super duplex alloy designed for superior corrosion resistance and very high mechanical strength. It offers excellent resistance to pitting, crevice corrosion, and chloride stress corrosion cracking, making it ideal for harsh and aggressive environments.

2507 is widely used in offshore platforms, desalination plants, chemical processing, and heat exchangers. Its high chromium, molybdenum, and nitrogen content ensure long-term performance in seawater, brine, and acidic chemical environments where both corrosion resistance and structural integrity are critical.

| Element | Content (%) |

| Chromium, Cr | 24 – 26 |

| Nickel, Ni | 6 – 8 |

| Molybdenum, Mo | 3 – 5 |

| Manganese, Mn | 1.20 max |

| Silicon, Si | 0.80 max |

| Copper, Cu | 0.50 max |

| Nitrogen, N | 0.24 – 0.32 |

| Phosphorous, P | 0.035 max |

| Carbon, C | 0.030 max |

| Sulfur, S | 0.020 max |

| Iron, Fe | Balance |

| Properties | Metric | Imperial |

| Density | 7.8 g/cm3 | 0.281 lb/in3 |

| Melting point | 1350°C | 2460°F |

| 0.2% Offset Yield Strength, ksi | 80 min. |

| Ultimate Tensile Strength, ksi | 116 min. |

| 1% Offset Yield Strength, ksi | 91 min. |

| Elongation in 2 inches, % | 15 min. |

| Hardness, Rockwell C | 32 max |

| Impact Energy, ft-lbs | 74 min. |

| Pipe Smls | Pipe Welded | Tube Smls | Tube Welded | Sheet/Plate | Bar | Flanges & Fittings |

| A790 | A790 | A789 | A789 | A240 | A276 | A182 |

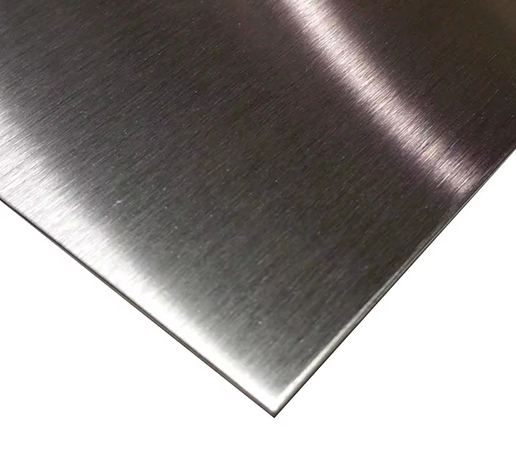

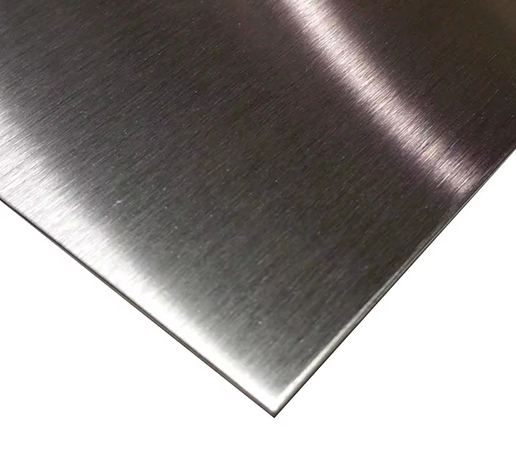

Standard product forms of 2507/S32750/1.4410 are pipe, tube, sheet, strip, plate, round bar, flat bar, forging stock, hexagon and wire. The products are available in a wide variety of sizes. Please contact us at [email protected] for full information.