Inconel X-750 (UNS N07750) is a nickel‑chromium‑iron superalloy strengthened by precipitation hardening with additions of aluminum and titanium. Known for excellent mechanical strength, creep resistance, and fatigue life at elevated temperatures, it is commonly used in aerospace components, turbine engines, nuclear reactors, and thermal processing equipment. The price of X‑750 depends on product form (bar, wire, sheet), heat treatment condition, surface finish, and certification. Below is a detailed price guide based on industrial market values.

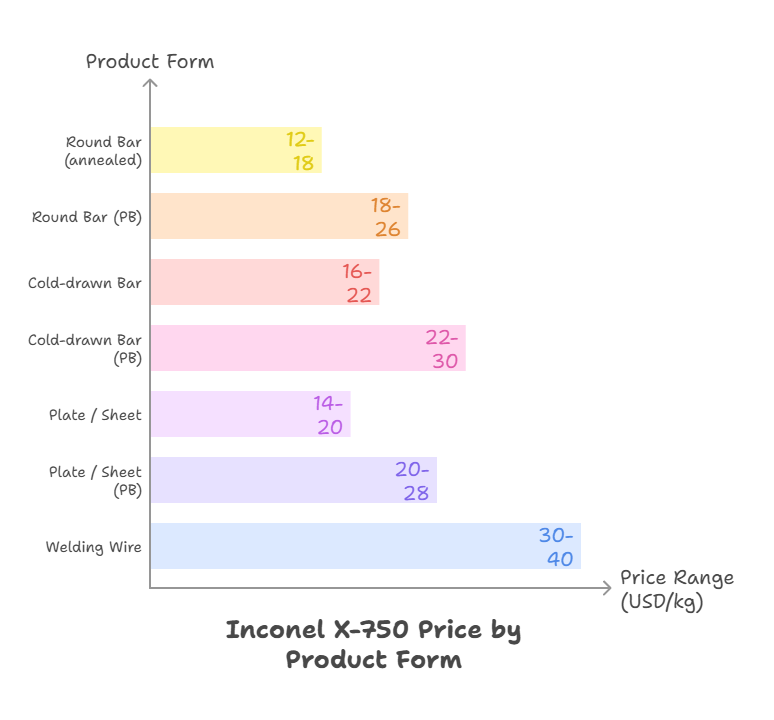

Inconel X‑750 Price by Product Form (USD/kg)

| نوع المنتج | Standard Condition | Precipitation‑Hardened (PB) |

|---|---|---|

| Round Bar (annealed) | $12 - $18 | N/A |

| Round Bar (PB, 980 °C + aging) | N/A | $18 - $26 |

| Cold‑drawn Bar | $16 – $22 | $22 - $30 |

| Plate / Sheet (≥2 mm) | $14 – $20 | $20 - $28 |

| Welding Wire (ERNiCrCoMo‑1) | N/A | $30 - $40 |

العوامل المؤثرة في الأسعار

| عامل | التأثير |

|---|---|

| Ni, Cr, Al, Ti Content | High alloy content significantly increases base cost |

| المعالجة الحرارية | Precipitation‑hardening adds complexity and raises price by 20–40% |

| الإنهاء | Bright‑drawn or peeled finishes cost more than mill‑surface |

| التصديق | Military, nuclear, or ASME 3.1/3.2 certificates add $2–5/kg |

| الكمية | Bulk orders (>1 t) reduce unit price by 5–10% |

Comparison with Other Inconel Alloys

| سبيكة | السعر النموذجي (دولار/كجم) |

|---|---|

| إنكونيل 600 | $8 - $20 |

| Inconel X‑750 | $12 – $30 |

| إنكونيل 625 | $15 - $28 |

Applications & Selection Tips

1. Turbine Components: Use precipitation-hardened X‑750 bar for high fatigue and creep performance.

2. Nuclear Fasteners: PB condition with NACE/ASME certification ensures radiation and stress resistance.

3. Repair & Welding: Use ERNiCrCoMo‑1 wire; expect $30–$40/kg due to high alloying.

4. Cost Optimization: For non-critical uses, annealed bar or plate provides adequate performance at lower cost.

أسئلة ذات صلة

What does precipitation-hardened Inconel X‑750 cost?

Precipitation-hardened X‑750 typically costs $18–$30/kg depending on form and finish.

Is Inconel X‑750 pricier than 600?

Yes—due to added Al and Ti for hardening, X‑750 costs about $4–$10/kg more than Inconel 600.

Where is Inconel X‑750 commonly used?

It is used in gas turbines, rocket engines, nuclear reactor hardware, and medical implants requiring long‑term strength at 500–700 °C.