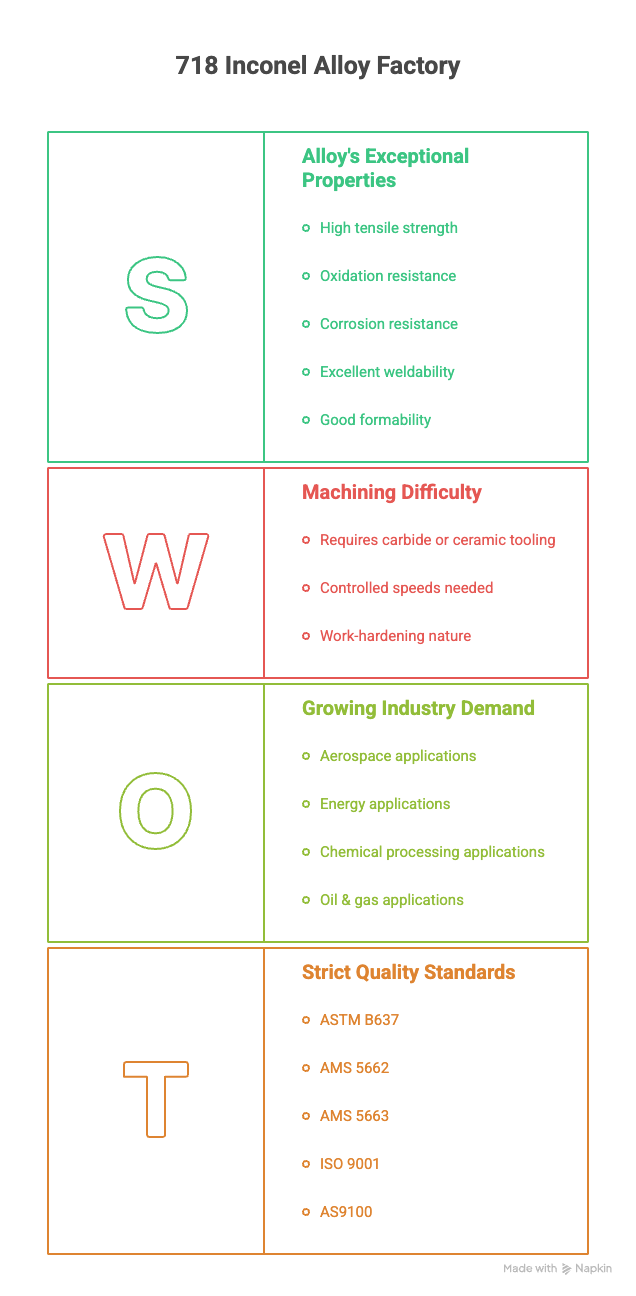

718 Inconel Alloy Factory specializes in the production of Inconel 718, a precipitation-hardened nickel-chromium alloy known for its exceptional strength, oxidation resistance, and corrosion resistance at temperatures up to 700°C. The alloy’s unique combination of high tensile, creep, and rupture strength makes it ideal for aerospace, energy, and chemical industries. Factories manufacturing Inconel 718 focus on strict metallurgical control and precision machining to meet the demanding requirements of industrial applications.

Overview of 718 Inconel Alloy

Inconel 718 (UNS N07718 / W.Nr. 2.4668) is a nickel-based superalloy that provides outstanding mechanical strength due to the precipitation of γ” and γ’ phases during heat treatment. It maintains excellent weldability and formability, making it a preferred material for complex parts in gas turbines, jet engines, and high-temperature fasteners.

Chemical Composition of Inconel 718

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50.0 – 55.0 |

| Chromium (Cr) | 17.0 – 21.0 |

| Iron (Fe) | Balance |

| Niobium + Tantalum (Nb+Ta) | 4.75 – 5.50 |

| Molydbenum (Mo) | 2.80 – 3.30 |

| Titanium (Ti) | 0.65 – 1.15 |

| Aluminum (Al) | 0.20 – 0.80 |

| Cobalt (Co) | ≤1.0 |

| Carbon (C) | ≤0.08 |

| Boron (B) | ≤0.006 |

Mechanical Properties of Inconel 718

| Property | Typical Value |

|---|---|

| Tensile Strength | 1250 MPa |

| Yield Strength (0.2% Offset) | 1035 MPa |

| Elongation | ≥12% |

| Hardness (Rockwell C) | ≤45 HRC |

| Working Temperature | -250°C to 700°C |

Production Process in 718 Inconel Alloy Factory

Factories specializing in 718 Inconel Alloy follow an advanced metallurgical process to ensure precision, uniform microstructure, and superior mechanical performance.

| Process Step | Description |

|---|---|

| Raw Material Inspection | Nickel, chromium, and alloying elements are checked for purity before melting. |

| Vacuum Induction Melting (VIM) | Initial melting ensures low gas content and uniform chemistry. |

| Vacuum Arc Remelting (VAR) | Enhances alloy cleanliness and microstructural homogeneity. |

| Forging or Rolling | Improves grain flow and mechanical strength for bars, plates, or forgings. |

| Heat Treatment | Solution annealing and aging processes optimize hardness and tensile strength. |

| Machining & Finishing | Precision cutting and surface finishing meet dimensional and surface quality standards. |

Common Products from 718 Inconel Alloy Factory

| Product Type | Size Range | Applications |

|---|---|---|

| Round Bar | 6mm – 300mm | Fasteners, shafts, and turbine components |

| Plate / Sheet | 1mm – 50mm thickness | Gas turbine casings and heat shields |

| Pipe / Tube | 6mm – 200mm OD | Heat exchangers and aerospace hydraulic systems |

| Forging / Ring | Custom size | Jet engine rings and high-stress components |

Applications of 718 Inconel Alloy

718 Inconel Alloy is favored in industries requiring high strength and oxidation resistance across extreme temperature ranges. Major application fields include:

1. Aerospace: Jet engine parts, turbine disks, exhaust systems, and fasteners.

2. Energy: Nuclear power, gas turbines, and steam generators.

3. Chemical Processing: Reaction vessels, heat exchangers, and high-pressure tubing.

4. Oil & Gas: Downhole tools, valves, and springs in corrosive environments.

Quality Testing in 718 Inconel Alloy Factories

Quality assurance is essential in every 718 Inconel Alloy factory. Each batch undergoes strict inspection to meet ASTM B637, AMS 5662, and AMS 5663 standards.

| Test Type | Description |

|---|---|

| Chemical Analysis | Spectrometric verification of alloy composition. |

| Mechanical Testing | Evaluation of tensile, hardness, and impact strength. |

| Ultrasonic Inspection | Detection of internal inclusions or defects. |

| Microstructure Examination | Ensures uniform precipitation and grain refinement. |

| Dimensional Accuracy | Precision measurement of bars, sheets, and tubes. |

Advantages of Choosing a Reliable 718 Inconel Alloy Factory

Partnering with a trusted Inconel 718 factory provides consistent quality and technical assurance:

• Certified Production: Factories certified under ISO 9001 and AS9100 standards.

• Advanced Equipment: State-of-the-art melting, forging, and machining lines ensure precision.

• Customization: Available in different sizes, tempers, and surface finishes according to project needs.

• Global Supply: Bulk orders shipped worldwide with complete documentation, including Mill Test Certificates (EN 10204 3.1).

Packing and Delivery

Finished 718 Inconel Alloy products are packed in wooden crates or iron boxes, wrapped with anti-rust paper and plastic film. Factories provide sea, air, and express shipping options with full traceability for each lot.

Related Questions

1. What makes Inconel 718 different from other nickel-based superalloys?

Inconel 718 offers superior strength due to its precipitation-hardening mechanism using niobium and titanium, while maintaining good weldability and formability compared to other alloys like Inconel 625 or 706.

2. Can Inconel 718 be machined easily?

Inconel 718 is machinable but requires carbide or ceramic tooling and controlled speeds due to its high strength and work-hardening nature. Many factories use CNC lathes optimized for superalloy machining.

3. What standards apply to 718 Inconel Alloy products?

Common standards include ASTM B637 for bars and forgings, AMS 5662 and AMS 5663 for aerospace-grade heat-treated materials, and ISO 6208 for international compliance.