Inconel 718 plate factory specializes in producing high-performance nickel-based superalloy plates known for exceptional strength, corrosion resistance, and high-temperature performance. Inconel 718, also designated as UNS N07718 or W.Nr. 2.4668, is widely used in aerospace, power generation, chemical processing, and marine industries. A reliable 718 Inconel plate factory ensures precision manufacturing, strict quality control, and compliance with international standards such as ASTM B637 and AMS 5596.

Overview of Inconel 718 Plate

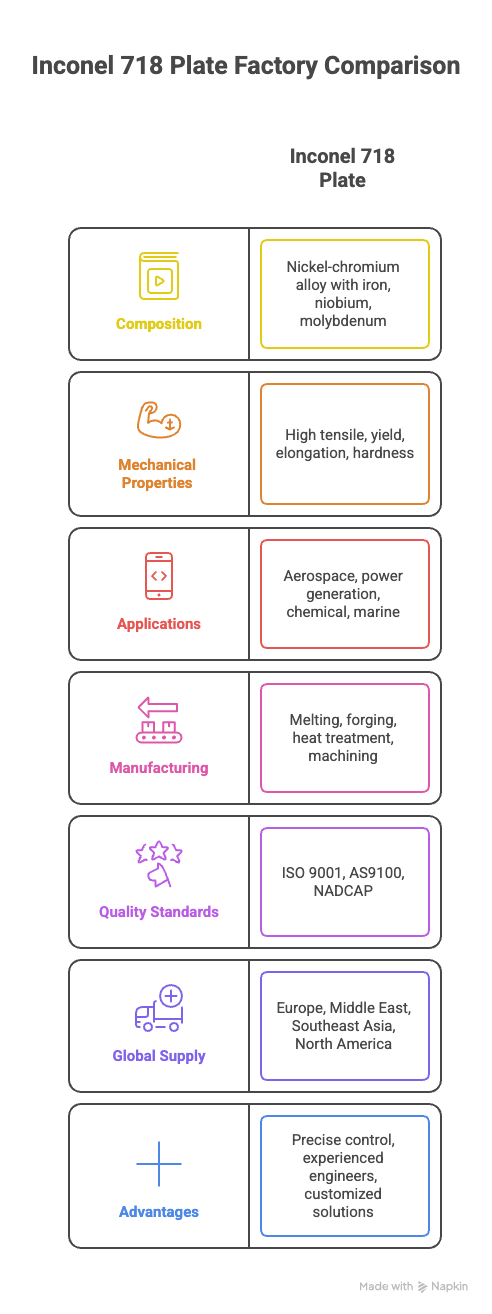

Inconel 718 is a precipitation-hardenable nickel-chromium alloy containing significant amounts of iron, niobium, and molybdenum. It offers excellent tensile, fatigue, creep, and rupture strength at temperatures up to 700°C. Due to its balanced composition, Inconel 718 maintains outstanding mechanical properties after heat treatment and welding.

| Grade | Standard | UNS Number | W.Nr. |

|---|---|---|---|

| Inconel 718 | ASTM B637 / AMS 5596 | N07718 | 2.4668 |

Chemical Composition of Inconel 718 Plate

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50–55 |

| Chromium (Cr) | 17–21 |

| Niobium + Tantalum (Nb + Ta) | 4.75–5.50 |

| Molybdenum (Mo) | 2.80–3.30 |

| Titanium (Ti) | 0.65–1.15 |

| Aluminum (Al) | 0.20–0.80 |

| Iron (Fe) | Balance |

Mechanical Properties of Inconel 718 Plate

| Property | Value | Condition |

|---|---|---|

| Tensile Strength | 1375 MPa min | Heat-treated |

| Yield Strength | 1100 MPa min | Heat-treated |

| Elongation | 12% min | Room Temperature |

| Hardness | Rockwell C 40 | Typical |

Applications of Inconel 718 Plate

Factories producing 718 Inconel plates supply industries that require materials capable of withstanding high stress and extreme environments. Common applications include:

- Gas turbine and jet engine components

- Rocket engines and spacecraft structures

- Oil and gas exploration tools

- Chemical processing heat exchangers

- High-strength fasteners and bolts

Manufacturing Process in 718 Inconel Plate Factory

Leading Inconel 718 plate factories employ advanced melting, forging, and heat treatment processes to ensure stable microstructure and mechanical integrity.

| Step | Description |

|---|---|

| 1. Melting | Vacuum induction melting (VIM) and vacuum arc remelting (VAR) ensure chemical homogeneity. |

| 2. Forging | Hot forging at 980–1200°C to refine grain structure. |

| 3. Heat Treatment | Solution annealing at 980°C followed by aging to precipitate γ” strengthening phase. |

| 4. Machining | Precision machining for dimensional accuracy. |

| 5. Inspection | Ultrasonic and eddy current tests for internal defect detection. |

Quality Standards and Certifications

Reputable 718 Inconel plate factories are certified under ISO 9001, AS9100, and NADCAP. Compliance with these standards ensures consistent quality, traceability, and reliable mechanical performance under critical conditions.

| Certification | Significance |

|---|---|

| ISO 9001 | Quality management system for manufacturing consistency. |

| AS9100 | Aerospace industry standard ensuring high performance materials. |

| NADCAP | Accreditation for special processes such as heat treatment and testing. |

Global Supply and Export Capability

Many Inconel 718 plate factories supply global markets including Europe, the Middle East, Southeast Asia, and North America. Export packages are customized according to client requirements, using seaworthy wooden crates and anti-rust wrapping to protect the plates during shipment.

Advantages of Choosing a Reliable 718 Inconel Plate Factory

| Feature | Benefit |

|---|---|

| Advanced Equipment | Ensures precise control of plate thickness and uniform mechanical properties. |

| Experienced Engineers | Optimize heat treatment and quality inspection procedures. |

| Customized Solutions | Support OEM and project-based requirements. |

| Competitive Price | Direct factory supply reduces procurement cost. |

Related Questions

1. What is Inconel 718 plate used for?

Inconel 718 plate is used for aerospace turbine components, gas turbines, chemical processing equipment, and high-temperature structural parts due to its strength and corrosion resistance.

2. What is the hardness of Inconel 718 plate?

The typical hardness of Inconel 718 plate after heat treatment is around Rockwell C 40, ensuring excellent wear resistance and mechanical strength.

3. What standards does Inconel 718 plate comply with?

Inconel 718 plate complies with ASTM B637, AMS 5596, and ISO quality management standards, guaranteeing material consistency and high performance.