The 825 nickel alloy welded pipe, also known as Incoloy 825 welded pipe, is a high-performance material widely used in chemical processing, pollution control, oil and gas recovery, and marine industries. This pipe is known for its exceptional corrosion resistance in aggressive environments, including sulfuric and phosphoric acid conditions. Pricing for 825 nickel alloy welded pipes depends on various factors such as pipe size, wall thickness, quantity, market fluctuations, and regional pricing differences. This article provides a comprehensive guide to understanding the price structure of 825 nickel alloy welded pipes.

Overview of 825 Nickel Alloy

Alloy 825 (UNS N08825) is a nickel-iron-chromium alloy with additions of molybdenum, copper, and titanium. It offers superior resistance to various corrosive environments, especially under reducing and oxidizing conditions. Its strength and corrosion resistance make it a popular choice for welded pipe manufacturing.

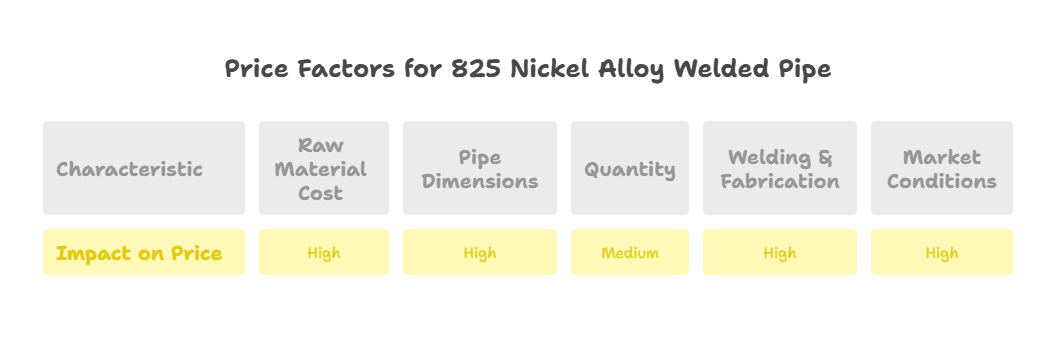

Key Price Determinants for 825 Nickel Alloy Welded Pipes

There are several primary factors that influence the pricing of welded pipes made from 825 nickel alloy. These include:

| Factor | Description |

|---|---|

| Raw Material Cost | The price of nickel, iron, chromium, and molybdenum significantly impacts the final pipe cost. |

| Pipe Dimensions | Diameter and wall thickness affect material usage and welding complexity, thus influencing the price. |

| Quantity | Bulk orders often result in lower unit costs due to economies of scale. |

| Welding & Fabrication | Special welding techniques and quality control increase fabrication costs. |

| Market Conditions | Nickel market volatility and demand-supply dynamics play a key role in monthly or quarterly price updates. |

Typical Price Range for 825 Nickel Alloy Welded Pipe

Prices can vary widely depending on location, supplier, and specification. The following table provides a general overview of typical market pricing (updated as of Q2 2025):

| Size (OD x WT) | Price Range (USD/ft) | Comments |

|---|---|---|

| 1″ x 0.083″ | $25 – $35 | Small diameter; used in instrumentation and fluid transfer |

| 2″ x 0.120″ | $35 – $50 | Common for chemical plant piping |

| 4″ x 0.188″ | $55 – $75 | Medium size; suitable for process lines |

| 6″ x 0.250″ | $80 – $110 | Larger size; used in high-corrosion environments |

Price Comparison: Seamless vs Welded 825 Pipes

Incoloy 825 pipes are available in both welded and seamless formats. Welded pipes are often more cost-effective due to lower manufacturing costs, but selection depends on application needs:

| Type | Price (USD/ft) | Features |

|---|---|---|

| Welded | $25 – $110 | Lower cost, good for most pressure and corrosion applications |

| Seamless | $40 – $140 | Higher strength, no weld seam, used in extreme environments |

Global Price Differences

Prices vary significantly by region due to logistics, import duties, and local market conditions:

| Region | Average Price (USD/ft) | Notes |

|---|---|---|

| North America | $35 – $100 | Strong demand in oil & gas sector |

| Europe | $40 – $110 | Regulatory standards drive higher pricing |

| Middle East | $30 – $90 | Bulk orders for offshore and petrochemical projects |

| Asia | $28 – $85 | Competitive pricing due to local production in China and India |

Additional Cost Factors: Testing and Certification

Many industries require third-party testing, certifications, and documentation, which can increase the final pipe cost. Common tests include:

| Test Type | Purpose | Cost Impact |

|---|---|---|

| Hydrostatic Testing | Verifies pipe strength under pressure | +2% to +5% |

| Ultrasonic Inspection | Detects internal flaws and weld integrity | +3% to +7% |

| PMI (Positive Material Identification) | Ensures correct alloy composition | +1% to +3% |

Supplier Selection and Its Impact on Price

The choice of supplier can significantly influence both price and quality. Consider the following when sourcing:

| Supplier Type | Advantages | Drawbacks |

|---|---|---|

| Manufacturer | Lower cost, direct customization, faster production | Minimum order quantity may be high |

| Stockist/Distributor | Quick delivery, wide range of sizes | Higher unit cost compared to factory direct |

FAQ: Related Questions

What is the price per foot of 825 nickel alloy welded pipe?

As of 2025, the price generally ranges between $25 to $110 per foot depending on pipe size, thickness, and market factors.

Is 825 alloy pipe more expensive than stainless steel?

Yes, 825 alloy pipes are significantly more expensive than standard stainless steels like 304 or 316 due to their nickel and molybdenum content and higher corrosion resistance.

Where can I buy Incoloy 825 welded pipe at the best price?

For the best pricing, consider purchasing directly from manufacturers or authorized distributors in Asia or the Middle East. Always request mill test certificates and verify compliance with ASTM B775 standards.