904L stainless steel bar is widely used in chemical processing, marine applications, pharmaceutical production, and heat exchanger components due to its superior resistance to acid corrosion and chloride stress corrosion cracking. Factories that manufacture 904L bars must ensure precision in metallurgy, forging, and testing to meet international quality standards like ASTM B649, ASTM A276, and EN 10088. This guide introduces leading global 904L stainless steel bar manufacturers, their capabilities, and factory highlights.

Top 904L Stainless Steel Bar Factories Worldwide

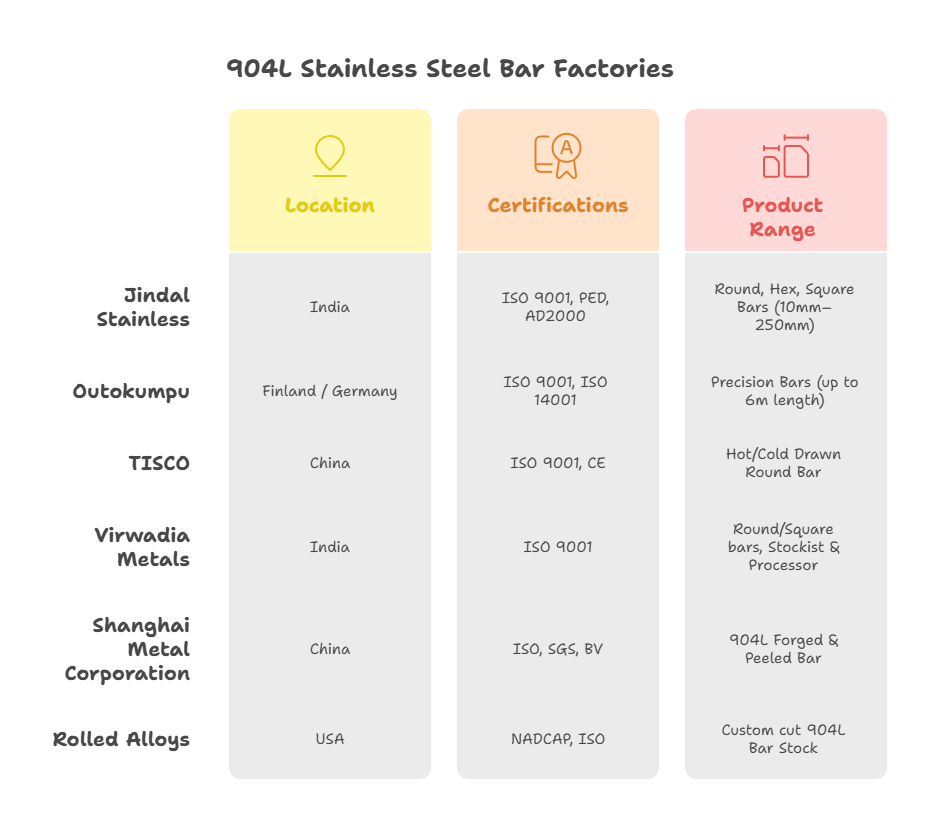

| Factory Name | Location | Certifications | Product Range |

|---|---|---|---|

| Jindal Stainless | India | ISO 9001, PED, AD2000 | Round, Hex, Square Bars (10mm–250mm) |

| Outokumpu | Finland / Germany | ISO 9001, ISO 14001 | Precision Bars (up to 6m length) |

| TISCO | China | ISO 9001, CE | Hot/Cold Drawn Round Bar |

| Virwadia Metals | India | ISO 9001 | Round/Square bars, Stockist & Processor |

| Shanghai Metal Corporation | China | ISO, SGS, BV | 904L Forged & Peeled Bar |

| Rolled Alloys | USA | NADCAP, ISO | Custom cut 904L Bar Stock |

Manufacturing Process for 904L Bars

1. Melting: EAF or AOD refining with precise alloy additions (Ni, Mo, Cu)

2. Hot Rolling: Ingot or billet rolled to bar sizes between 10mm and 300mm

3. Heat Treatment: Solution annealing at ~1100°C to optimize corrosion resistance

4. Surface Finish: Polished, peeled, rough-turned, or bright drawn based on end use

5. Inspection: Ultrasonic testing, PMI (Positive Material ID), mechanical testing

Available Bar Types and Sizes

| Type | Standard Size Range | Finish |

|---|---|---|

| Round Bar | Ø 10mm – Ø 250mm | Polished / Peeled / Black |

| Hex Bar | Across flats 8mm – 60mm | Bright Drawn |

| Square Bar | 10mm – 100mm | Cold Drawn |

| Flat Bar | 10 x 3 mm to 150 x 30 mm | Hot Rolled / Polished |

Typical Applications of 904L Stainless Steel Bar

• Chemical Process Plants: Used in heat exchangers and piping components handling sulfuric acid

• Marine Engineering: Propeller shafts and structural rods resistant to seawater corrosion

• Pharmaceuticals: Reactor bars and support structures with high hygienic demand

• Desalination Plants: Support bars in brine environments

Factory Selection Tips

1. Choose Certified Producers: Look for ISO, PED, or NORSOK certified facilities

2. Verify Traceability: Request full material trace documents (Mill Test Certificates)

3. Consider Proximity: Choose local stockists for quick delivery or mills for bulk pricing

4. Request Custom Machining: Many factories offer cut-to-length, threading, or turning services

Related Questions

Where can I find 904L stainless steel bar manufacturers?

Manufacturers are located in India (Jindal, Virwadia), China (TISCO, SMC), Europe (Outokumpu), and the U.S. (Rolled Alloys).

What types of 904L stainless steel bars are available?

Available types include round bars, square bars, hex bars, and flat bars in sizes ranging from 10mm to 250mm with various surface finishes.

Which standards apply to 904L stainless steel bars?

Common standards include ASTM B649, ASTM A276, ASTM A479, and EN 10088 for mechanical and chemical requirements.