A battery nickel strip factory specializes in producing nickel strips used for battery pack welding, energy-storage systems, EV batteries, and consumer electronics. These factories focus on purity, thickness accuracy, surface finish, conductivity, and weldability to ensure stable electrical performance. A reliable battery nickel strip factory must control raw materials, rolling technology, plating quality, and mechanical properties to meet modern battery manufacturing standards.

Main Capabilities of a Battery Nickel Strip Factory

Battery nickel strip factories manufacture pure nickel strips, nickel-plated strips, and custom-width battery tabs. Their capabilities directly affect cell consistency, welding stability, and current-carrying capacity. Factories often supply strips used for cylindrical, pouch, and prismatic battery assemblies.

| Capability | Description |

| Material Type | Pure Nickel (Ni 99.6%), Nickel-Plated Steel, Nickel-Copper Alloys |

| Thickness Range | 0.08–0.3 mm for common battery welding |

| Width Range | 2 mm–50 mm depending on battery size |

| Cutting Methods | Slitting, stamping, laser cutting |

Types of Nickel Strips Manufactured

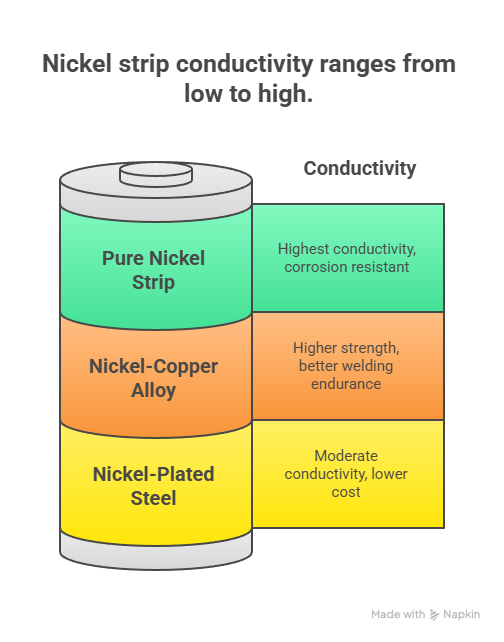

Different factories supply multiple types of nickel strips depending on the application. Pure nickel strips offer the highest conductivity, while nickel-plated steel provides lower cost for large-volume packs. Understanding the difference helps buyers choose the correct type for their battery system.

| Type | Features | Use Case |

| Pure Nickel Strip | High conductivity, corrosion resistant | High-end lithium batteries |

| Nickel-Plated Steel | Cheaper, moderate conductivity | Low-cost consumer devices |

| Nickel-Copper Alloy Strip | Higher strength, better welding endurance | EV battery packs |

Production Processes in a Nickel Strip Factory

A battery nickel strip factory uses advanced rolling and plating technology to maintain uniform thickness and stable surface conditions. Strict control during production ensures strips meet battery welding requirements.

| Process | Purpose |

| Cold/Hot Rolling | Achieves precision thickness and smooth surface |

| Annealing | Improves ductility for spot welding |

| Electroplating | Uniform nickel coating for steel-based strips |

| Slitting & Cutting | Creates accurate widths for battery assembly |

Quality Standards for Battery Nickel Strip Factories

Factories follow multiple testing standards to ensure their nickel strips can handle high current without overheating or breaking. Testing includes conductivity, tensile strength, plating adhesion, and corrosion resistance.

| Quality Test | Why It Matters |

| Nickel Purity Test | Determines real conductivity performance |

| Tensile Strength | Prevents cracking during spot welding |

| Surface Roughness | Affects welding stability |

| Plating Uniformity | Ensures long-term corrosion resistance |

How to Choose a Reliable Battery Nickel Strip Factory

When selecting a supplier, buyers must confirm material authenticity, production stability, and quality documentation. Many cheap suppliers mislabel nickel-plated steel as pure nickel, which leads to poor welding results.

| Selection Factor | Importance |

| Material Certification | Ensures purity is genuine (Ni ≥ 99.6%) |

| Factory Scale | Larger factories offer stable supply and consistent quality |

| Welding Test Report | Shows performance under real battery assembly conditions |

| Customization Ability | Custom widths, plating thickness, and shapes |

Applications of Nickel Strips from Factories

Nickel strips manufactured by battery strip factories are used across consumer electronics, energy storage systems, electric vehicles, drones, power tools, and communication batteries. Their performance directly affects battery safety and lifespan.

| Application | Requirement |

| Lithium-ion Battery Packs | High conductivity and strong welding strength |

| Energy Storage | Long-term corrosion resistance |

| Electric Vehicles | High mechanical strength and thermal stability |

| Consumer Electronics | Stable welding at low current |

FAQ

1. What purity should a battery nickel strip factory provide?

High-quality factories provide pure nickel strips with purity around 99.6% or higher to ensure good electrical conductivity.

2. How does a factory ensure nickel strips are suitable for spot welding?

Factories control thickness, anneal the material, test tensile strength, and check surface uniformity to guarantee stable welding performance.

3. What types of battery packs use factory-made nickel strips?

Nickel strips are widely used in lithium-ion battery packs for electronics, EVs, energy storage, drones, and power tools.