China hosts numerous advanced factories specializing in the production of Incoloy 800 tubes, a high-performance nickel-iron-chromium alloy known for its excellent strength and resistance to oxidation and carburization at elevated temperatures. Incoloy 800 tubes are extensively used in heat exchangers, petrochemical processing, furnace components, and nuclear steam generators. Chinese manufacturers supply both seamless and welded Incoloy 800 tubes, often adhering to international standards such as ASTM B407 and ASTM B514. This guide introduces leading factories, product specifications, finishes, and export capabilities of Chinese Incoloy 800 tube suppliers.

Specifications of Incoloy 800 Tubes

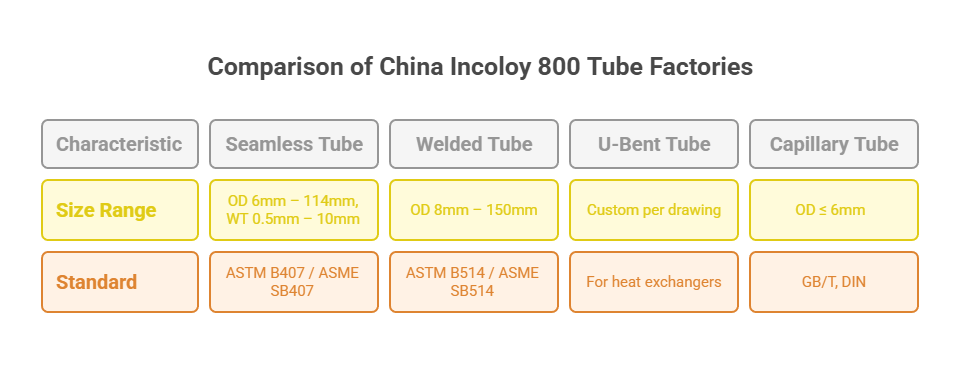

Chinese factories offer a variety of tube sizes, forms, and tolerances to suit a wide range of industrial applications.

| Tube Type | Size Range | Standard |

|---|---|---|

| Seamless Tube | OD 6mm – 114mm, WT 0.5mm – 10mm | ASTM B407 / ASME SB407 |

| Welded Tube | OD 8mm – 150mm | ASTM B514 / ASME SB514 |

| U-Bent Tube | Custom per drawing | For heat exchangers |

| Capillary Tube | OD ≤ 6mm | GB/T, DIN |

Top Incoloy 800 Tube Factories in China

These factories are recognized for their expertise in nickel alloy tube manufacturing and global export capabilities:

| Factory Name | Location | Core Products |

|---|---|---|

| Jiangsu Huacheng Industry Pipe Making Co., Ltd. | Wuxi, Jiangsu | Seamless nickel alloy tubes and U-bend tubes |

| Yuhong Group Co., Ltd. | Zhejiang | Nickel alloy seamless and welded tubes |

| Zhejiang Yiding Pipe Manufacturing Co., Ltd. | Longwan, Zhejiang | Incoloy and Inconel heat exchanger tubes |

| Wenzhou Chiron Alloy Materials Co., Ltd. | Wenzhou, Zhejiang | Bright annealed and polished tubes |

| Jiangsu Nickel Alloy Co., Ltd. | Changzhou, Jiangsu | Precision nickel alloy tubing |

Surface Finishes and Treatments

Incoloy 800 tubes are available in several finish options based on customer requirements:

| Finish | Description | Application |

|---|---|---|

| Bright Annealed | Controlled atmosphere annealing | Clean surface, instrumentation |

| Pickled | Acid-treated to remove scale | Corrosion-resistant piping systems |

| Polished (180–600 grit) | Mechanically or electro-polished | Pharmaceutical and decorative use |

Certifications Provided by Chinese Tube Factories

Reputable Incoloy 800 tube factories in China supply full certification for global compliance:

| Certification | Description |

|---|---|

| ISO 9001 | Certified quality management system |

| EN 10204 3.1 / 3.2 | Mill Test Certificate (MTC) |

| ASME / ASTM Compliance | Material and dimensional accuracy |

| CE / PED Certification | EU pressure equipment compliance |

FAQs About China Incoloy 800 Tube Factories

Where are the top Incoloy 800 tube factories located in China?

They are mainly based in Jiangsu and Zhejiang provinces, especially in cities like Wuxi, Wenzhou, and Changzhou.

Do Chinese factories export ASTM-certified Incoloy 800 tubes?

Yes, most factories export globally and comply with ASTM B407 and ASTM B514 standards, with full MTC documentation.

What is the difference between seamless and welded Incoloy 800 tubes?

Seamless tubes are extruded and offer superior pressure resistance, while welded tubes are cost-effective and suitable for low- to medium-pressure systems.