Nickel foil is a thin, precision-engineered metal product widely used in batteries, electronics, aerospace, and chemical processing. China has become a global leader in nickel foil manufacturing due to its advanced rolling technology, low-cost production, and strong material science expertise. Understanding the major nickel foil factories in China helps global buyers find reliable suppliers, evaluate pricing trends, and ensure consistent quality standards.

Top China Nickel Foil Manufacturers

China has dozens of reputable nickel foil factories that specialize in producing high-purity and nickel-based alloy foils. Below are some of the most recognized manufacturers in this field.

| Factory Name | Location | Main Products | Website |

|---|---|---|---|

| Wuxi Seather Technology Co., Ltd. | Wuxi, Jiangsu | Nickel alloy foil, Inconel foil, Monel foil | https://seathertechnology.com |

| Baoji Hanz Material Technology Co., Ltd. | Baoji, Shaanxi | Pure nickel foil, Ni-Ti alloy, titanium foil | https://hanzwmo.com |

| Shanghai Tankii Alloy Material Co., Ltd. | Shanghai | Nickel foil, resistance alloy foil, nichrome foil | https://tankii.com |

| Hunan Hualiu New Material Co., Ltd. | Changsha, Hunan | Battery-grade nickel foil, precision rolled foil | https://hualiumetal.com |

| Jiangsu Nickel Alloy Co., Ltd. | Suqian, Jiangsu | Nickel strip, foil, and thin sheet | https://jsnickel.com |

Nickel Foil Price in China

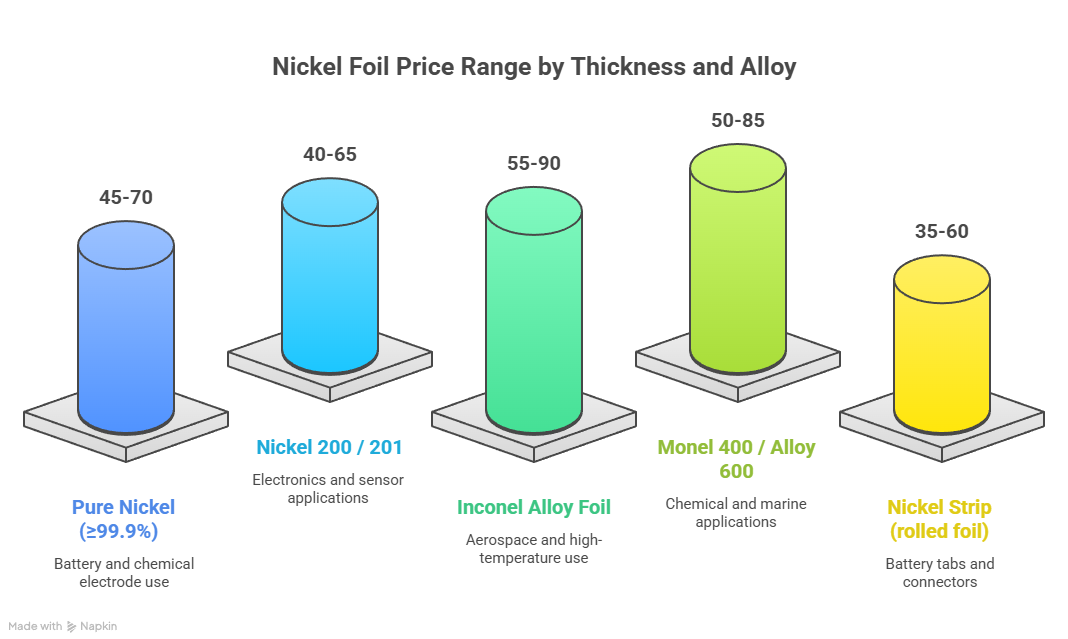

The price of nickel foil in China depends on its thickness, alloy composition, and surface treatment. High-purity nickel foil and nickel-based alloy foils are priced higher due to production complexity and quality control standards.

| Thickness (mm) | Alloy Type | Approx. Price (USD/kg) | Application |

|---|---|---|---|

| 0.01 – 0.03 | Pure Nickel (≥99.9%) | 45 – 70 | Battery, chemical electrode |

| 0.03 – 0.10 | Nickel 200 / 201 | 40 – 65 | Electronics, sensors |

| 0.10 – 0.20 | Inconel Alloy Foil | 55 – 90 | Aerospace, high temperature |

| 0.20 – 0.30 | Monel 400 / Alloy 600 | 50 – 85 | Chemical and marine applications |

| Above 0.30 | Nickel Strip (rolled foil) | 35 – 60 | Battery tabs, connectors |

Production Capabilities of Chinese Nickel Foil Factories

Chinese nickel foil manufacturers use advanced cold rolling and precision slitting technologies to produce uniform, ultra-thin foils. Their capabilities are summarized as follows:

| Production Feature | Typical Specification |

|---|---|

| Thickness Range | 0.005 mm to 0.3 mm |

| Width Range | Up to 400 mm |

| Surface Finish | Bright annealed, matte, or polished |

| Purity | ≥99.9% for pure nickel |

| Annual Capacity | 200 – 800 tons per year |

| Quality Standards | ISO 9001, ASTM B162, GB/T 2059 |

Applications of Nickel Foil Made in China

Nickel foil produced by Chinese manufacturers is widely used in multiple industries thanks to its superior mechanical and chemical performance.

| Industry | Application | Specification Example |

|---|---|---|

| Battery Manufacturing | Current collectors for lithium and hydrogen batteries | 0.02mm thick, high purity Ni 99.9% |

| Electronics | Electromagnetic shielding and sensors | 0.05mm bright foil |

| Aerospace | Heat shielding and fuel system components | Alloy 600, 0.1mm |

| Chemical Equipment | Corrosion-resistant lining | Nickel 201 foil, 0.2mm |

| Medical Devices | Precision conductive components | 0.03mm Ni foil, polished |

Advantages of Choosing Chinese Nickel Foil Factories

Chinese nickel foil factories offer competitive pricing, scalable production, and strict quality control. The country’s well-developed metal supply chain enables consistent raw material sourcing and cost efficiency.

| Advantage | Description |

|---|---|

| Cost Efficiency | Lower labor and production costs compared to Western manufacturers. |

| Technological Capability | Advanced precision rolling, vacuum annealing, and surface treatment facilities. |

| Customization | Flexible options for thickness, width, and packaging based on customer needs. |

| Export Experience | Many factories regularly export to North America, Europe, and Asia-Pacific regions. |

| Stable Supply Chain | Integrated production from nickel refining to foil rolling ensures consistent quality. |

How to Choose the Right China Nickel Foil Factory

When sourcing from China, buyers should carefully evaluate suppliers based on production capacity, certification, and export experience. Below are the main criteria:

| Selection Criterion | Why It Matters |

|---|---|

| Material Certification | Ensure compliance with ASTM or GB standards to verify quality. |

| Minimum Order Quantity (MOQ) | Factories vary in MOQ requirements from 50 kg to 500 kg. |

| Sample Availability | Request samples before placing bulk orders to confirm material consistency. |

| Lead Time | Typical delivery period ranges from 2 to 6 weeks depending on order size. |

| After-Sales Support | Choose suppliers offering technical assistance and documentation. |

Market Trends of Nickel Foil in China

The Chinese nickel foil market is growing rapidly, driven by electric vehicle battery production and advanced electronics manufacturing. Government investment in new energy industries is boosting demand for high-purity nickel foil. However, raw material price fluctuations and export restrictions can affect overall pricing. Technological improvements in rolling mills and foil processing are expected to stabilize prices over the next few years.

Related Questions

1. What is the price of nickel foil from China?<b