Cobalt alloy strips are precision-rolled materials made from cobalt-based alloys known for their exceptional heat resistance, corrosion resistance, and high strength. These strips are widely used in aerospace, medical implants, electronics, and energy industries. This article introduces major global and Chinese suppliers, available cobalt strip grades, production standards, and applications. It also provides key selection factors and export capabilities.

Popular Grades of Cobalt Alloy Strips

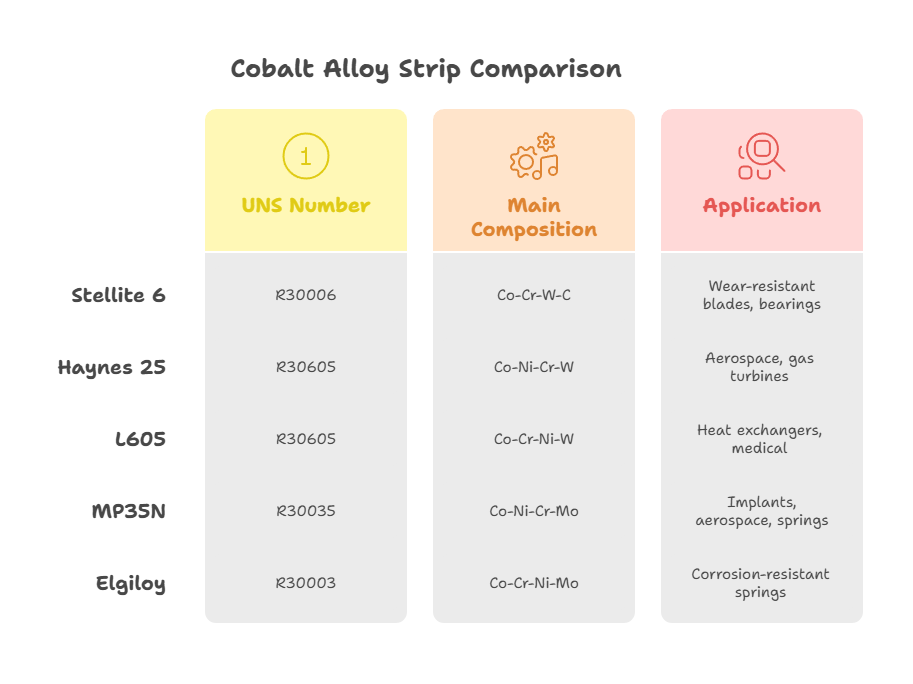

| Grade | UNS Number | Main Composition | Application |

|---|---|---|---|

| Stellite 6 | R30006 | Co-Cr-W-C | Wear-resistant blades, bearings |

| Haynes 25 | R30605 | Co-Ni-Cr-W | Aerospace, gas turbines |

| L605 | R30605 | Co-Cr-Ni-W | Heat exchangers, medical |

| MP35N | R30035 | Co-Ni-Cr-Mo | Implants, aerospace, springs |

| Elgiloy | R30003 | Co-Cr-Ni-Mo | Corrosion-resistant springs |

Major Cobalt Alloy Strip Suppliers

| Company | Location | Grades Offered | Certifications |

|---|---|---|---|

| Ulbrich Stainless Steels & Special Metals | USA | MP35N, L605, Elgiloy | ISO 9001, AS9100 |

| Haynes International | USA | Haynes 25, L605 | NADCAP, ISO |

| AMETEK Specialty Metal Products | USA/UK | MP35N, Cobalt-Chrome | AMS, ISO |

| Baosteel Special Metals | China | Stellite 6, Haynes 25 | ISO 9001, PED |

| Hunan Fushun Metal | China | MP35N, Elgiloy | ISO, SGS |

| Shanghai HY Industry | China | Haynes 25, L605, Stellite | EN10204 3.1, ISO |

Available Strip Sizes

| Thickness Range | Width Range | Tolerance | Hardness |

|---|---|---|---|

| 0.03 mm – 2.5 mm | 3 mm – 400 mm | ±0.005 mm | Annealed to Spring Temper |

Production Standards

ASTM F562: Covers MP35N and Elgiloy strips for surgical implants and aerospace use.

AMS 5537: Standard for Haynes 25 sheet and strip used in aerospace engines.

ASTM F90: Cobalt-Chromium implant strip standard (e.g., for heart valves).

Applications of Cobalt Alloy Strip

• Aerospace: High-temperature components, engine seals

• Medical: Cardiovascular implants, stents, surgical instruments

• Electronics: High-strength contact strips and springs

• Energy: Fuel cell separators, heat exchanger fin materials

Packaging & Export

| Packing Method | Lead Time | MOQ | Shipping Method |

|---|---|---|---|

| Plastic + Wooden Box | 7–30 days | 10 kg – 50 kg | DHL, FedEx, Sea |

How to Choose a Cobalt Strip Supplier

• Certifications: Ensure ISO, PED, or ASTM-compliant materials

• Tolerance Control: Look for ±0.01 mm or better in strip thickness

• Custom Widths: Check if slit-to-width service is offered

• Technical Support: Reliable suppliers offer alloy selection guidance and material data sheets

Related Questions

Who are reliable suppliers of cobalt alloy strips?

Top suppliers include Ulbrich (USA), Haynes (USA), Shanghai HY (China), and Fushun Metal (China), offering high-quality MP35N, L605, and Elgiloy strips.

What sizes are available for cobalt alloy strips?

Strips typically range from 0.03 mm to 2.5 mm thick and 3 mm to 400 mm wide, with options for annealed or cold-rolled spring temper.

Which cobalt alloys are best for medical and aerospace use?

MP35N and Elgiloy are ideal for medical implants, while Haynes 25 and L605 are widely used in aerospace applications due to heat resistance.