Copper nickel tube manufacturers produce high-performance copper-nickel alloy tubes used in marine, HVAC, desalination, chemical processing, and offshore applications. These tubes are valued for excellent corrosion resistance, high thermal conductivity, and durability in seawater and aggressive environments. Ncalloys is a trusted copper nickel tube manufacturer offering customized tube sizes, certification support, and global delivery to meet industrial requirements.

About Ncalloys Copper Nickel Tubes

Ncalloys specializes in manufacturing copper nickel alloy tubes with precise dimensions, consistent quality, and documentation for international standards. Our copper nickel tubes are designed to withstand long-term exposure to seawater, salt spray, and corrosive fluids, making them ideal for shipbuilding, power plants, and marine heat exchangers.

Manufacturer: Ncalloys

Contact Email: [email protected]

Copper Nickel Tube Materials Offered

Copper nickel tubes are available in various alloy grades, each optimized for specific corrosion resistance and mechanical properties.

| Alloy | Typical Composition | Common Use |

|---|---|---|

| Copper Nickel 70/30 (Cu-Ni 70/30) | 70% Cu, 30% Ni | Marine piping, seawater systems |

| Copper Nickel 90/10 (Cu-Ni 90/10) | 90% Cu, 10% Ni | Heat exchangers, desalination tubes |

| Cu-Ni with Fe/Mn Additions | 90/10 + Fe/Mn | Improved strength and corrosion resistance |

Key Features of Copper Nickel Tubes

Copper nickel tubes combine mechanical strength, corrosion resistance, and thermal performance.

| Feature | Benefit |

|---|---|

| Corrosion Resistance | Outstanding resistance to seawater and chloride stress corrosion |

| Thermal Conductivity | High conductivity for heat exchanger applications |

| Mechanical Strength | Good strength at elevated temperatures |

| Low Fouling | Resists marine growth and deposits |

Applications of Copper Nickel Tubes

Copper nickel tubes are widely used in industries where long-term corrosion resistance and durability are critical.

| Industry | Application |

|---|---|

| Marine & Shipbuilding | Seawater piping, cooling lines, heat exchangers |

| Power Generation | Condenser tubes and cooling systems |

| Desalination | Reverse osmosis and heat transfer tubes |

| HVAC | Air conditioning and refrigeration systems |

Manufacturing Capabilities

Ncalloys offers comprehensive copper nickel tube manufacturing capabilities to satisfy custom industrial requirements.

| Service | Description |

|---|---|

| Custom Diameter & Thickness | Precise sizing for specific system requirements |

| Cut-to-Length Options | Tubes supplied ready for fabrication |

| Testing & Inspection | Hydrostatic, dimensional, and material analysis |

| Documentation Support | Mill test certificates and compliance reports |

Quality Standards and Certification

Ncalloys ensures compliance with international specifications for copper nickel tube materials.

| Standard | Purpose |

|---|---|

| ASTM B111 | Copper-Nickel Seamless Condenser and Heat Exchanger Tubes |

| ASTM B466 | Seamless and Welded Copper-Nickel Tubes |

| ISO 9001 | Quality management system certification |

| EN / DIN Standards | European market compliance |

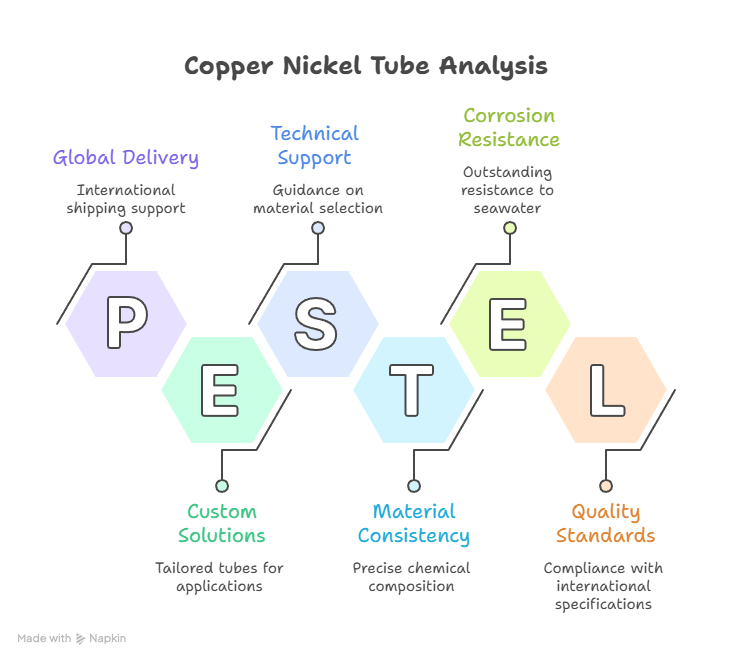

Why Choose Ncalloys Copper Nickel Tubes

Ncalloys offers not only material supply but also engineering support and reliable delivery.

| Advantage | Benefit |

|---|---|

| Material Consistency | Precise chemical composition and mechanical performance |

| Custom Solutions | Tailored tubes for unique applications |

| Technical Support | Guidance on material selection and application conditions |

| Global Logistics | Fast response and international shipping support |

Related Questions

1. What industries commonly use copper nickel tubes?

Copper nickel tubes are commonly used in marine, power generation, desalination, and HVAC systems due to their corrosion resistance and thermal conductivity.

2. What copper nickel alloy grades are used for tubes?

The most common grades are 70/30 (70% copper, 30% nickel) and 90/10 (90% copper, 10% nickel), with optional Fe/Mn for improved strength.

3. How do I contact Ncalloys for copper nickel tube inquiries?

You can contact Ncalloys by email at [email protected] for pricing, technical support, and order details.