Copper‑nickel alloy pipe fittings (commonly 90/10 or 70/30 Cu‑Ni, and Monel variants) are essential in marine, offshore, chemical, and power applications due to their outstanding corrosion resistance—especially in seawater—and mechanical durability. Choosing the right manufacturer ensures compliance with industry standards, quality procurement, and reliable supply chains. This guide highlights top manufacturers, key specifications, production standards, and sourcing strategies.

What Are Copper‑Nickel Pipe Fittings?

Copper‑nickel pipe fittings connect sections of Cu‑Ni piping systems and include elbows, tees, reducers, caps, couplings, flanges, and more. Alloys such as C70600 (90/10), C71500 (70/30) and Monel 400 are selected for their resistance to seawater corrosion, biofouling, and acidic/alkaline environments.

Global Manufacturers Overview

| Manufacturer | Country | Alloys | Details |

|---|---|---|---|

| Kwality Pipe & Tube Industries | India | C70600 (90/10), C71500 (70/30) | Seamless/welded buttweld & forged fittings in sizes ¼”–28″ ASME/ASTM certified |

| Honesty Metal Industries | India | C70600, C71500 | Seamless, welded & fabricated; exports to 60+ countries; ISO 9001, PED |

| Technoforge Pipe & Fittings | India | 90/10, 70/30 | Buttweld, socket weld, threaded; marine/oil‑gas focus |

| Copperry | China | CuNi 90/10, 70/30 | Factory-direct pricing; CCS, LR, DNV-GL, ABS approved |

| Tork Systems | USA | 70/30 & 90/10 | Backing rings, 70/30 elbows up to 12″, MIL‑SPEC compliant |

| McMaster‑Carr | USA | Unspecified Cu‑Ni | Stock threaded/socket welded fittings; REACH & RoHS compliant |

| Alaskan Copper & Brass Co. | USA (West Coast) | 90/10, 70/30 | Seamless/welded fittings & tubing; marine focus |

Specifications & Product Range

| Specification | Coverage |

|---|---|

| Alloy Grades | C70600 (90/10), C71500 (70/30), Monel 400 |

| Fitting Types | Elbows (45°, 90°, long/short radius), tees (equal/unequal), reducers (eccentric/concentric), caps, couplings, flanges, backing rings, forged/socket/threaded components |

| Size Range | From ¼″ up to 28″ NB (Sch 10S–XXS) |

| Standards | ASTM B466/467/151/152, ASME B16.9/B16.28, MSS SP‑43/B16.3, MIL‑SPEC, PED, CCS, DNV‑GL, ABS |

Applications of Cu‑Ni Fittings

Marine & Naval Systems: Condensers, seawater piping, heat exchangers; resist biofouling due to protective film formation

Power Plants: Used in condensers, chillers, brine systems, undergoing continuous seawater exposure

Oil & Gas / Offshore: Handles splash-zone piping, hydraulic lines, and sour-water service; MIL‑SPEC and NACE requirements are vital

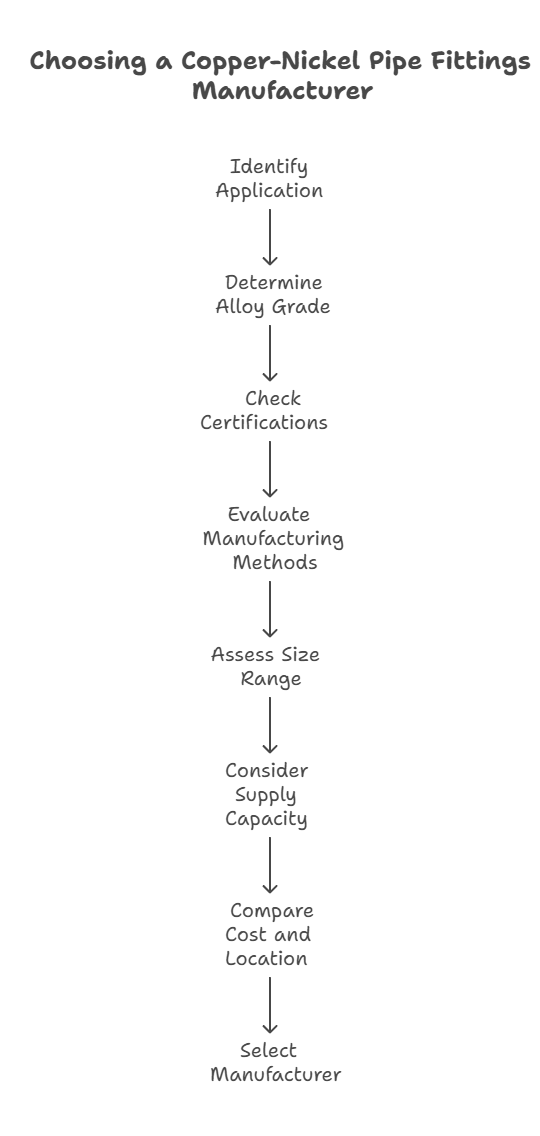

Choosing a Manufacturer

Certification & Quality: Look for ISO 9001, PED, NAVSEA/MIL‑SPEC, CCS/DNV‑GL/ABS approvals for marine services.

Manufacturing Methods: Seamless fittings offer structural integrity; forged and socket-weld fittings ensure pressure resilience.

Range & Sizes: Prefer suppliers offering up to 28″ sizes and XXS schedules.

Supply & Export Capacity: Suppliers like Kwality and Honesty have proven export reach; McMaster offers local inventory.

Cost & Location: Indian and Chinese manufacturers offer competitive pricing, but also consider freight, duties, and lead times.

Frequently Asked Questions

What grades of Cu‑Ni are commonly used for pipe fittings?

The most common grades are C70600 (90% copper / 10% nickel) and C71500 (70/30 Cu‑Ni). These alloys resist seawater corrosion and biofouling, making them ideal for marine and industrial applications .

Which manufacturers supply Cu‑Ni fittings to marine and offshore sectors?

Major suppliers include Kwality Pipe & Tube Industries and Honesty Metal (India), Technoforge (India), Copperry (China), Tork Systems (USA), and Alaskan Copper & Brass Co. (USA West Coast). Many hold certifications like CCS, DNV-GL, ABS, MIL‑SPEC, and PED .

How do I verify the quality of Cu‑Ni fittings?

Check for compliance with ASTM/ASME/MIL specs, confirm alloy grade and certificates (MTRs), ensure proper manufacturing type (seamless or forged), and confirm approvals like ABS, NAVSEA, PED, or DNV-GL depending on application.