Inconel 625 is a premium-grade nickel-based superalloy recognized for its excellent corrosion resistance, high strength, and resistance to extreme temperatures. Due to its unique chemical composition and complex manufacturing process, the cost of Inconel 625 is significantly higher than standard stainless steels or industrial alloys. This article provides a comprehensive breakdown of the current Inconel 625 costs by form, influencing factors, and trusted suppliers in 2025.

Average Cost of Inconel 625 in 2025

| Form | Common Sizes | Cost Range (USD/KG) | Notes |

|---|---|---|---|

| Sheet / Plate | 1.0 – 10 mm thick | 45 – 65 | Available in ASTM B443 |

| Bar / Rod | 10 – 100 mm dia | 50 – 70 | ASTM B446 standard |

| Pipe / Tube | 6 – 219 mm OD | 55 – 75 | Seamless pipes are more expensive |

| Wire | 0.5 – 3.2 mm | 60 – 85 | Used for welding and springs |

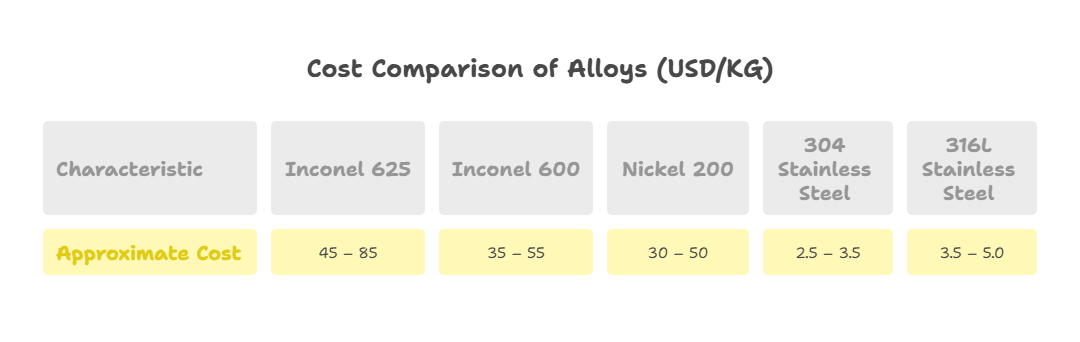

Cost Comparison with Other Alloys

| Alloy | Approximate Cost (USD/KG) | Notes |

|---|---|---|

| Inconel 625 | 45 – 85 | Premium nickel alloy |

| Inconel 600 | 35 – 55 | Lower molybdenum content |

| Nickel 200 | 30 – 50 | Purer nickel, less strength |

| 304 Stainless Steel | 2.5 – 3.5 | Basic stainless alloy |

| 316L Stainless Steel | 3.5 – 5.0 | Marine-grade SS |

Major Cost Factors of Inconel 625

• Nickel Content: With about 58% nickel, price is heavily affected by LME nickel rates.

• Alloying Elements: Molybdenum, chromium, niobium also add to cost.

• Manufacturing Method: Seamless tubes, cold-rolled sheets, or precision wire increase production costs.

• Certification: Items meeting ASTM B443/B444/B446 and EN standards are priced higher.

• Origin & Logistics: Products from the US and EU are costlier than those from China or India.

Inconel 625 Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20.0 – 23.0 |

| Molybdenum (Mo) | 8.0 – 10.0 |

| Niobium (Nb) | 3.15 – 4.15 |

| Iron (Fe) | 5.0 max |

Top Global Suppliers of Inconel 625

| Company | Country | Main Products | Certifications |

|---|---|---|---|

| Special Metals | USA | Inconel bars, sheets, pipes | ASTM, ISO, ASME |

| VDM Metals | Germany | Plates, coils, wires | EN, PED, ISO |

| Jiangsu Nickel-Tech | China | Sheets, forged bars | ASTM B443/B446 |

| Yuhong Group | China | Seamless pipes and fittings | ISO 9001, API 5L |

| Metline Industries | India | Alloy pipes and flanges | ASTM, PED |

Market Trends in 2025

Due to increased demand in aerospace, LNG, and energy sectors, the global demand for Inconel 625 continues to rise. The prices are expected to remain elevated in 2025 compared to 2023–2024 due to strong raw material costs and energy prices. Price volatility is closely tied to global nickel production and geopolitical supply chain risks.

Applications That Justify the High Cost

• Aerospace: Jet engines, afterburners, exhaust ducts

• Oil & Gas: Subsea equipment, sour gas tubing

• Marine: Heat exchangers, seawater components

• Chemical Processing: Acid storage tanks, reactors

Related Questions

What is the current cost of Inconel 625 per kg?

As of 2025, the cost ranges from $45 to $85 per kg depending on product form and supplier.

Why is Inconel 625 expensive?

It contains a high percentage of costly nickel and molybdenum, and involves complex processing standards.

Is Inconel 625 more expensive than stainless steel?

Yes, it is significantly more expensive, often 10 to 20 times the price of 304 or 316 stainless steel.