Nickel 200 and Nickel 201 are both commercially pure wrought nickel alloys commonly used in chemical processing, electrical applications, aerospace, and food handling. Although similar in composition, the main difference between Nickel 200 and 201 lies in their carbon content, which significantly affects their temperature stability and mechanical performance. This article compares the two grades in terms of composition, physical properties, corrosion resistance, and recommended applications in 2025.

Chemical Composition Comparison of Nickel 200 vs. Nickel 201

| Element | Nickel 200 (UNS N02200) | Nickel 201 (UNS N02201) | Effect |

|---|---|---|---|

| Nickel (Ni) | ≥ 99.5% | ≥ 99.5% | Base element |

| Carbon (C) | ≤ 0.15% | ≤ 0.02% | Lower carbon in 201 prevents embrittlement at high temp |

| Iron (Fe) | ≤ 0.40% | ≤ 0.40% | Minor impurity |

| Sulfur (S) | ≤ 0.01% | ≤ 0.01% | Affects corrosion and formability |

Mechanical Properties Comparison

| Property | Nickel 200 | Nickel 201 | Remarks |

|---|---|---|---|

| Tensile Strength (MPa) | ≥ 380 | ≥ 370 | Nickel 200 slightly stronger at room temperature |

| Yield Strength (MPa) | ≥ 100 | ≥ 85 | Nickel 200 better suited for structural applications |

| Elongation (%) | ≥ 45 | ≥ 50 | Nickel 201 offers better ductility |

| Melting Point (°C) | 1435 | 1435 | Same for both |

Key Differences Between Nickel 200 and 201

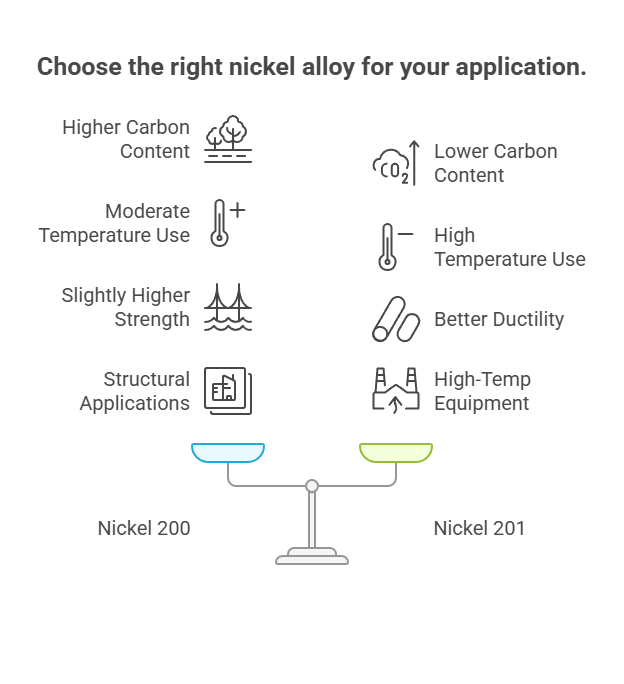

1. Carbon Content: Nickel 201 has significantly lower carbon (≤ 0.02%) than Nickel 200 (≤ 0.15%), making it more resistant to graphitization at elevated temperatures above 315°C.

2. Temperature Performance: Nickel 201 is recommended for high-temperature applications (above 315°C), while Nickel 200 is more suitable for low to moderate temperature environments.

3. Applications: Nickel 200 is often used in structural parts, electronics, and general corrosion-resistant components. Nickel 201 is used in high-temperature processing equipment, such as caustic evaporators and thermocouple sheaths.

4. Price: Prices are generally similar, but Nickel 201 can be slightly more expensive due to its controlled low-carbon composition and special use cases in high-temp environments.

Applications Comparison

| Application | Nickel 200 | Nickel 201 |

|---|---|---|

| Battery terminals | ✓ | ✓ |

| Caustic evaporators | ✗ | ✓ |

| Electrical components | ✓ | ✓ |

| Thermocouple protection tubes | ✗ | ✓ |

| Food processing | ✓ | ✓ |

Which Alloy Should You Choose?

Choose Nickel 200: If your application involves moderate temperatures, requires slightly higher strength, and doesn’t exceed 300°C.

Choose Nickel 201: If the operating temperature is above 315°C or involves prolonged exposure to high-heat conditions where carbon-induced embrittlement must be avoided.

Related Questions and Answers

Is Nickel 201 better than Nickel 200?

Nickel 201 is better for high-temperature applications due to its lower carbon content. However, Nickel 200 provides better mechanical strength at room temperature, making it ideal for general structural and electrical uses.

Can Nickel 200 and Nickel 201 be used interchangeably?

They are often interchangeable for room-temperature applications, but for elevated temperatures, only Nickel 201 should be used to avoid graphitization and material failure.

Is there a price difference between Nickel 200 and 201 in 2025?

The price difference is minimal, usually within 3–5%. Nickel 201 may be slightly higher due to stricter carbon controls and niche applications.