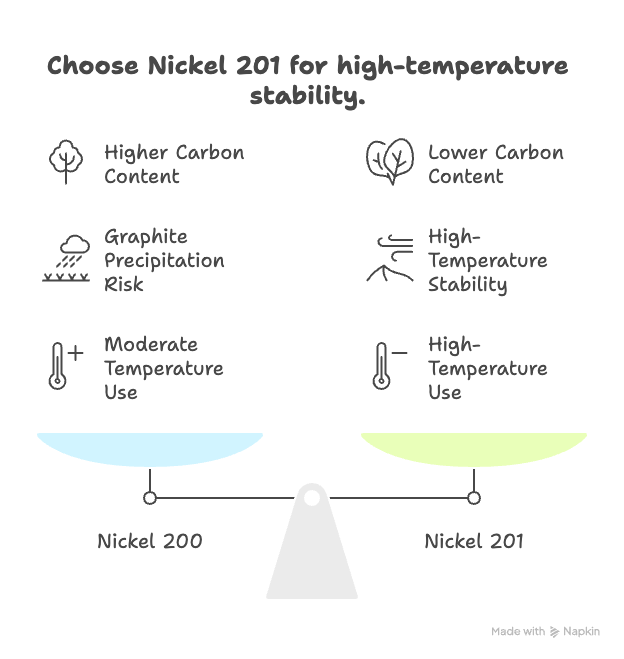

Nickel 200 and Nickel 201 are commercially pure nickel alloys that are very similar in composition, corrosion resistance, and mechanical properties. The primary difference between them is carbon content, which directly affects their performance at elevated temperatures. Choosing the correct grade depends mainly on the service temperature and long-term thermal stability requirements.

Basic Definition of Nickel 200 and Nickel 201

Nickel 200 is a commercially pure wrought nickel alloy with a minimum nickel content of 99.0%. It offers excellent corrosion resistance in reducing environments and good mechanical properties at room and moderate temperatures.

Nickel 201 is a low-carbon version of Nickel 200. It retains the same high nickel purity but significantly reduces carbon content to improve performance at higher temperatures and prevent material degradation.

Chemical Composition Difference

The key chemical difference lies in carbon content, while other elements remain nearly identical.

| Element | Nickel 200 | Nickel 201 |

|---|---|---|

| Nickel (Ni) | 99.0 min | 99.0 min |

| Carbon (C) | ≤ 0.15 | ≤ 0.02 |

| Iron (Fe) | ≤ 0.40 | ≤ 0.40 |

| Manganese (Mn) | ≤ 0.35 | ≤ 0.35 |

| Silicon (Si) | ≤ 0.35 | ≤ 0.35 |

| Copper (Cu) | ≤ 0.25 | ≤ 0.25 |

High-Temperature Performance Difference

The most important practical difference between Nickel 200 and Nickel 201 is their behavior at elevated temperatures.

Nickel 200 is susceptible to graphite precipitation when exposed to temperatures above 315°C (600°F) for extended periods. This precipitation can reduce ductility and negatively affect mechanical performance.

Nickel 201, with its much lower carbon content, eliminates the risk of graphite formation. As a result, it is suitable for continuous service at temperatures up to about 600°C (1110°F).

Mechanical Properties Comparison

At room temperature, both alloys show nearly identical mechanical properties.

| Property | Nickel 200 | Nickel 201 |

|---|---|---|

| Tensile Strength | ≈ 480–585 MPa | ≈ 480–585 MPa |

| Yield Strength | ≈ 140–240 MPa | ≈ 140–240 MPa |

| Elongation | ≈ 30–45% | ≈ 30–45% |

| Recommended Max Service Temp | 315°C | 600°C |

Corrosion Resistance

Nickel 200 and Nickel 201 offer essentially the same corrosion resistance because their chemical compositions are nearly identical aside from carbon.

Both alloys perform very well in caustic alkalis, organic acids, dry gases, and reducing environments. They also show good resistance to corrosion in controlled marine and chemical processing conditions.

Fabrication and Weldability

Both Nickel 200 and Nickel 201 are easy to fabricate. They can be cold-formed, hot-worked, and welded using standard nickel alloy welding procedures.

Nickel 201 is generally preferred for welded components that will operate at high temperatures because it maintains ductility and structural stability after prolonged heat exposure.

Typical Applications

Nickel 200: Chemical processing equipment, food processing components, electronics, battery components, heat exchangers operating at moderate temperatures.

Nickel 201: High-temperature chemical equipment, furnace components, heat treatment baskets, aerospace and industrial parts exposed to sustained heat.

How to Choose Between Nickel 200 and Nickel 201

If the operating temperature stays below 315°C and cost is a consideration, Nickel 200 is usually sufficient. For applications involving prolonged exposure to higher temperatures, Nickel 201 is the safer and more reliable choice.

Related Questions

What is the main difference between Nickel 200 and Nickel 201?

The main difference is carbon content, which gives Nickel 201 better high-temperature stability.

Can Nickel 200 and Nickel 201 be used interchangeably?

They can be interchangeable at low temperatures, but Nickel 201 should be used for high-temperature applications.

Why is Nickel 201 preferred for high-temperature service?

Its ultra-low carbon content prevents graphite precipitation, preserving ductility and mechanical integrity at elevated temperatures.