Factory price Inconel 718 bar is an ideal choice for buyers seeking high-strength, corrosion-resistant nickel-based superalloy bars directly from the manufacturing source. Inconel 718 (UNS N07718 / W.Nr. 2.4668) is widely used in aerospace, marine, petrochemical, and power generation industries due to its exceptional mechanical properties and outstanding resistance to heat and oxidation. Purchasing Inconel 718 bars at factory price ensures better cost efficiency, traceable quality, and reliable delivery from certified manufacturers.

Overview of Inconel 718 Bar

Inconel 718 bar is a precipitation-hardened nickel-chromium alloy containing niobium, molybdenum, titanium, and aluminum. It provides excellent tensile, creep, and rupture strength at temperatures up to 700°C. Factories producing Inconel 718 bars strictly follow standards such as ASTM B637 and AMS 5662, ensuring consistent metallurgical quality and performance.

| Grade | Standard | UNS | W.Nr. |

|---|---|---|---|

| Inconel 718 | ASTM B637 / AMS 5662 / AMS 5663 | N07718 | 2.4668 |

Chemical Composition of Inconel 718 Bar

| Element | Percentage (%) |

|---|---|

| Nickel (Ni) | 50–55 |

| Chromium (Cr) | 17–21 |

| Niobium + Tantalum (Nb + Ta) | 4.75–5.50 |

| Molybdenum (Mo) | 2.80–3.30 |

| Titanium (Ti) | 0.65–1.15 |

| Aluminum (Al) | 0.20–0.80 |

| Iron (Fe) | Balance |

Mechanical Properties of Inconel 718 Bar

| Property | Typical Value | Condition |

|---|---|---|

| Tensile Strength | 1375 MPa | Heat Treated |

| Yield Strength | 1100 MPa | Heat Treated |

| Elongation | 12% | Room Temperature |

| Hardness | Rockwell C 40 | Typical |

Available Sizes and Dimensions

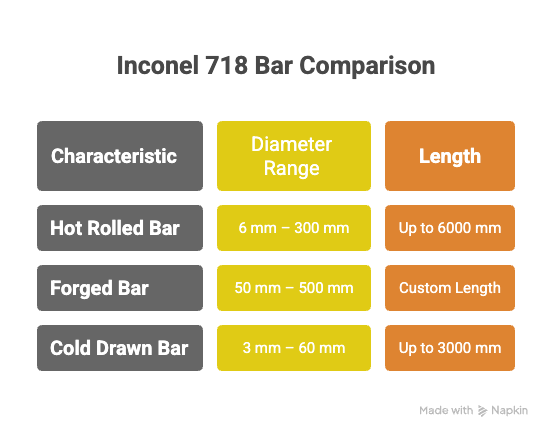

Factories can produce Inconel 718 bars in both hot-rolled and forged forms, customized to specific requirements for aerospace or industrial applications.

| Type | Diameter Range | Length |

|---|---|---|

| Hot Rolled Bar | 6 mm – 300 mm | Up to 6000 mm |

| Forged Bar | 50 mm – 500 mm | Custom Length |

| Cold Drawn Bar | 3 mm – 60 mm | Up to 3000 mm |

Factory Price Advantage

Buying directly from an Inconel 718 bar factory helps reduce intermediary costs and ensures a consistent price-to-quality ratio. Prices vary depending on bar size, production process, and surface finish, but factory supply guarantees competitive rates and certified quality.

| Parameter | Influence on Price |

|---|---|

| Diameter | Larger diameters cost more due to higher material input. |

| Heat Treatment | Aged bars are more expensive than annealed ones. |

| Surface Finish | Polished bars cost more than black surface bars. |

| Order Quantity | Bulk orders enjoy factory discounts. |

Manufacturing Process of Inconel 718 Bar

Top factories adopt advanced metallurgical processes to ensure the bar’s homogeneity, strength, and durability under extreme conditions.

| Step | Process Description |

|---|---|

| 1. Melting | Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR) for purity and consistency. |

| 2. Forging | Hot forged to improve grain structure and toughness. |

| 3. Heat Treatment | Solution annealing followed by aging for precipitation hardening. |

| 4. Machining | Precision machining for dimensional tolerance. |

| 5. Inspection | Ultrasonic and hardness testing ensure defect-free quality. |

Applications of Inconel 718 Bar

Due to its high strength and corrosion resistance, Inconel 718 bar is used in several demanding environments:

- Aerospace turbine shafts and jet engine components

- Oil and gas drilling tools

- High-strength bolts and fasteners

- Nuclear reactor structural parts

- Chemical processing machinery

Why Choose a Certified Inconel 718 Bar Factory

Factories certified under ISO 9001, AS9100, and NADCAP offer assurance of superior quality control and traceability.

| Certification | Purpose |

|---|---|

| ISO 9001 | Ensures consistent quality and process control. |

| AS9100 | Meets aerospace and defense material standards. |

| NADCAP | Guarantees accredited heat treatment and inspection processes. |

Related Questions

1. What is the factory price of Inconel 718 bar per kilogram?

The factory price of Inconel 718 bar generally ranges between $45 and $70 per kilogram depending on size, condition, and quantity, with bulk orders offering significant discounts.

2. What sizes are available for Inconel 718 bar?

Factories typically produce Inconel 718 bars in diameters ranging from 3 mm to 500 mm, suitable for machining, forging, and aerospace components.

3. How does heat treatment affect the price of Inconel 718 bar?

Heat-treated or aged Inconel 718 bars cost more than annealed ones due to the additional processing and enhanced mechanical properties achieved during aging.