Nickel 200 tubing is widely recognized for its excellent corrosion resistance, high thermal conductivity, and outstanding mechanical properties. It is commonly used in chemical processing, marine applications, and heat exchangers. Purchasing Nickel 200 tubing at factory prices allows manufacturers and end-users to reduce costs while ensuring material quality. In this article, we provide a comprehensive overview of Nickel 200 tubing, including specifications, advantages, applications, and pricing trends.

Overview of Nickel 200 Tubing

Nickel 200, also known as UNS N02200, is a commercially pure nickel grade with over 99% nickel content. It is highly resistant to alkalis, acids, and various chemical environments. Tubing made from Nickel 200 can be supplied in various forms, including seamless and welded tubes, to meet diverse industrial requirements.

Specifications

| Property | Specification |

|---|---|

| Material | Nickel 200 (UNS N02200) |

| Standard | ASTM B161 / B165 / B162 |

| Form | Seamless / Welded |

| Diameter Range | OD: 6–100 mm, ID: 2–95 mm |

| Wall Thickness | 0.5–5 mm |

| Temper | Annealed (soft), Cold Drawn |

| Surface Finish | Mill Finish / Polished |

Advantages of Nickel 200 Tubing

Nickel 200 tubing offers several key benefits, which make it suitable for high-demand industrial applications:

| Advantage | Description |

|---|---|

| Corrosion Resistance | Exceptional resistance to acids, alkalis, and reducing agents, ideal for chemical plants and seawater applications. |

| High Thermal Conductivity | Efficient heat transfer makes it suitable for heat exchangers and boilers. |

| Mechanical Strength | Maintains structural integrity at elevated temperatures up to 600°C. |

| Fabrication Ease | Can be easily welded, bent, and formed without cracking. |

| Longevity | Durable under aggressive industrial conditions, reducing maintenance costs. |

Applications of Nickel 200 Tubing

Nickel 200 tubing is used across multiple industries due to its unique combination of properties:

| Industry | Application |

|---|---|

| Chemical Processing | Reaction vessels, heat exchangers, piping for acids and alkalis |

| Marine & Offshore | Seawater piping, condensers, desalination plants |

| Aerospace | Fuel systems, high-temperature exhaust components |

| Electronics | Vacuum equipment, batteries, and connectors |

| Food & Beverage | Processing lines exposed to corrosive cleaning agents |

Pricing Trends for Factory Nickel 200 Tubing

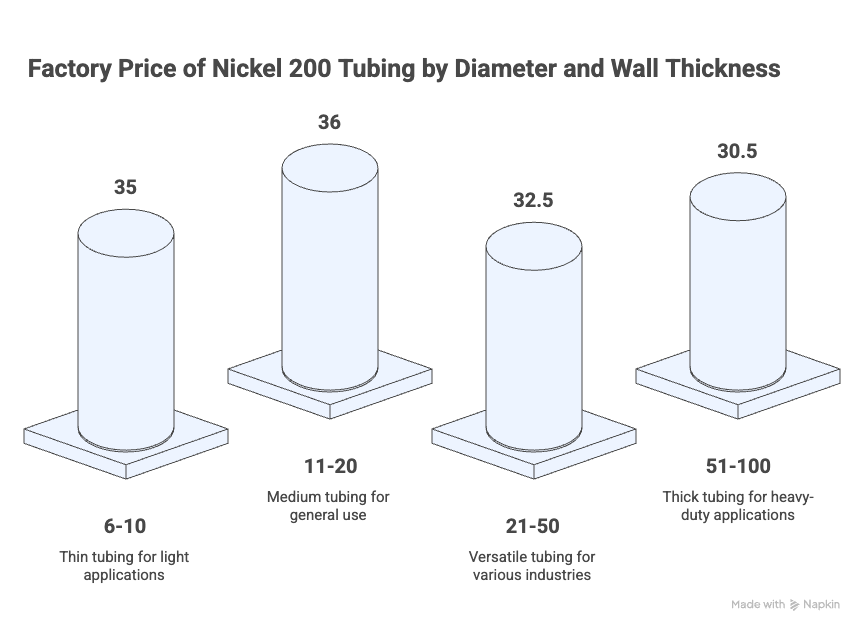

Factory pricing for Nickel 200 tubing depends on material thickness, diameter, and order quantity. Purchasing directly from factories often reduces costs compared to distributors.

| Diameter (mm) | Wall Thickness (mm) | Price per kg (USD) |

|---|---|---|

| 6–10 | 0.5–1 | 35–40 |

| 11–20 | 1–2 | 33–38 |

| 21–50 | 2–3 | 30–35 |

| 51–100 | 3–5 | 28–33 |

Tips for Buying Nickel 200 Tubing at Factory Prices

To ensure you get the best value:

- Request a direct quotation from certified factories.

- Check the material certification (ASTM/UNS standard).

- Consider bulk orders to lower unit cost.

- Compare seamless vs welded tubes based on application.

- Evaluate shipping and import costs when purchasing internationally.

Maintenance and Handling

Nickel 200 tubing requires minimal maintenance. However, proper handling ensures long service life:

- Avoid exposure to highly oxidizing acids like nitric acid.

- Store in a dry environment to prevent surface contamination.

- Clean with non-abrasive agents to maintain surface finish.

- Inspect periodically for cracks or mechanical damage.

Related Questions:

1. What is the price of Nickel 200 tubing per kilogram?

The factory price of Nickel 200 tubing ranges from approximately $28 to $40 per kg depending on the diameter and wall thickness.

2. What are the main applications of Nickel 200 tubing?

Nickel 200 tubing is commonly used in chemical processing, marine environments, aerospace fuel systems, electronics, and food & beverage processing.

3. What standards should Nickel 200 tubing comply with?

Nickel 200 tubing should comply with ASTM B161/B165/B162 standards and the UNS N02200 specification to ensure material quality and performance.