Factory price nickel alloy bar is one of the most demanded products in the metal industry due to its excellent corrosion resistance, high mechanical strength, and ability to perform under extreme conditions. Nickel alloy bars are produced in various grades such as Nickel 200/201, Monel 400, Inconel 600/625, Hastelloy C22/C276, and Incoloy 800/825. These materials are widely used in aerospace, chemical processing, marine, power generation, and oil & gas industries. Understanding the factors affecting factory price nickel alloy bar helps buyers make informed purchasing decisions.

Nickel Alloy Bar Grades and Chemical Composition

Different nickel alloy grades provide varying performance. The following table summarizes key grades and their main elements:

| Alloy | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) | Copper (Cu) |

|---|---|---|---|---|---|

| Nickel 200/201 | 99 min | – | – | 0.40 max | 0.25 max |

| Monel 400 | 63 min | – | – | 2.50 max | 28-34 |

| Inconel 600 | 72 min | 14-17 | – | 6-10 | – |

| Inconel 625 | 58 min | 20-23 | 8-10 | 5 max | – |

| Incoloy 825 | 38-46 | 19.5-23.5 | 2.5-3.5 | 22 max | 1.5-3.0 |

| Hastelloy C276 | 50-57 | 14.5-16.5 | 15-17 | 4-7 | – |

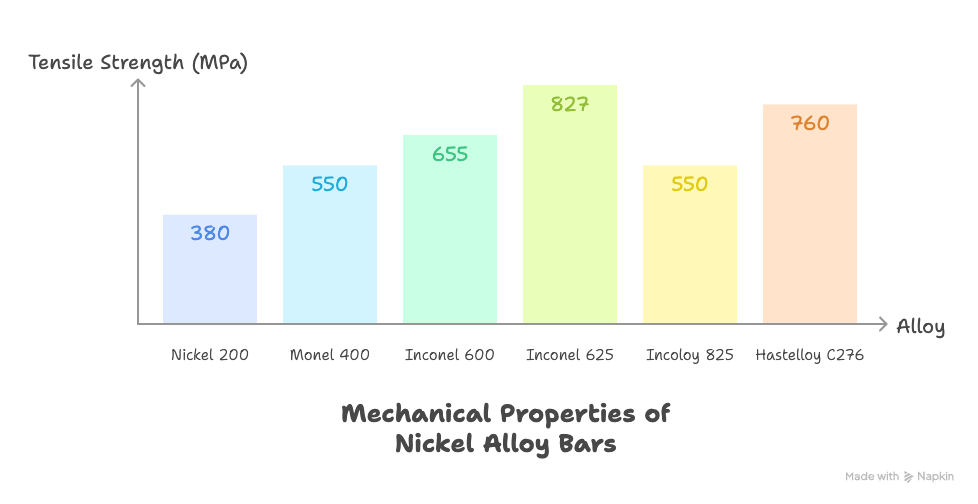

Mechanical Properties of Nickel Alloy Bars

Nickel alloy bars deliver high strength and toughness across a wide temperature range. The mechanical properties vary by grade, as shown below:

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HRB) |

|---|---|---|---|---|

| Nickel 200 | 380 | 105 | 40 | 60 |

| Monel 400 | 550 | 240 | 35 | 65 |

| Inconel 600 | 655 | 310 | 30 | 85 |

| Inconel 625 | 827 | 414 | 30 | 92 |

| Incoloy 825 | 550 | 220 | 30 | 80 |

| Hastelloy C276 | 760 | 283 | 40 | 95 |

Factors Affecting Factory Price Nickel Alloy Bar

The cost of nickel alloy bars depends on multiple factors, including:

- Nickel and molybdenum market price fluctuations

- Grade and alloy composition (higher alloy content means higher cost)

- Bar diameter, length, and surface finish (bright, black, or polished)

- Manufacturing process (hot rolled, forged, or cold drawn)

- Order volume and supplier certifications (ISO, ASTM, ASME compliance)

- Logistics, delivery terms, and location of the factory

Applications of Nickel Alloy Bars

Nickel alloy bars are widely applied in environments requiring corrosion resistance, strength, and heat stability:

| Industry | Applications |

|---|---|

| Chemical Processing | Reactor vessels, mixing shafts, pump shafts |

| Oil & Gas | Drilling equipment, valves, downhole tools |

| Aerospace | Engine shafts, turbine blades, exhaust components |

| Marine | Propeller shafts, seawater equipment, offshore structures |

| Power Generation | Nuclear reactor components, steam generator parts |

Advantages of Buying Direct from Factory

Purchasing nickel alloy bars directly from a factory offers clear benefits:

- Lower prices without middleman margins

- Customization in dimensions, grades, and finishes

- Reliable quality control with mill test certificates

- Faster delivery schedules

- Access to technical support and after-sales service

Related Questions and Answers

What is the price of nickel alloy bar per kg?

The price of nickel alloy bar per kg depends on the alloy grade, size, and market conditions, usually higher than stainless steel due to its nickel and molybdenum content.

Where can I buy nickel alloy bars at factory price?

You can purchase directly from manufacturers or certified suppliers who offer mill test certificates and competitive bulk pricing.

Which nickel alloy bar is best for high-temperature use?

Inconel 625 and Hastelloy C276 bars are highly recommended for high-temperature and corrosive environments due to their superior strength and oxidation resistance.