Hastelloy bolts command premium pricing due to their exceptional corrosion resistance in aggressive environments. This guide examines current market pricing structures, identifies leading global suppliers, and analyzes key factors affecting costs for various Hastelloy grades including C276, C22, B2, and B3 bolts used in chemical processing, oil/gas, and marine applications.

Price Ranges by Alloy and Grade (2024)

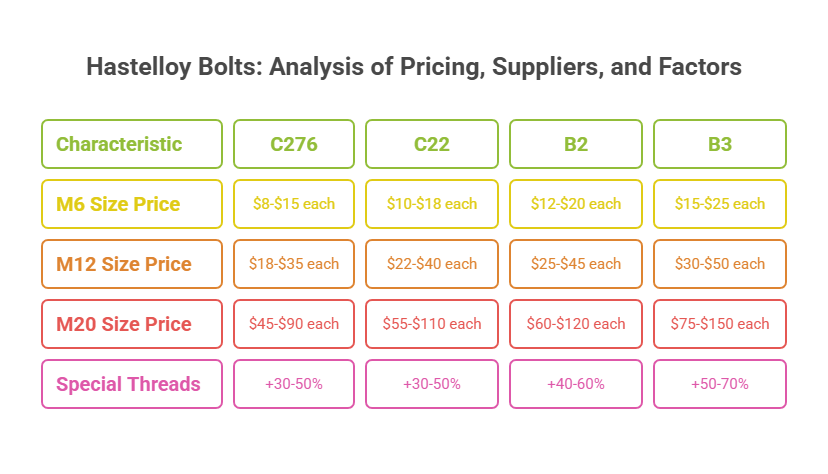

Current market pricing for standard hex head bolts:

| Alloy | M6 Size | M12 Size | M20 Size | Special Threads |

|---|---|---|---|---|

| C276 | $8-$15 each | $18-$35 each | $45-$90 each | +30-50% |

| C22 | $10-$18 each | $22-$40 each | $55-$110 each | +30-50% |

| B2 | $12-$20 each | $25-$45 each | $60-$120 each | +40-60% |

| B3 | $15-$25 each | $30-$50 each | $75-$150 each | +50-70% |

Note: Prices reflect standard ASME B16.5/B18.2.1 compliant bolts in quantities of 100+, with 20-30% premium for smaller orders.

Leading Global Suppliers

Major certified Hastelloy bolt manufacturers:

| Supplier | Headquarters | Specializations | Certifications |

|---|---|---|---|

| Haynes International | USA | Full alloy range | ASME, NACE, PED |

| Special Metals | UK/USA | Large diameter | ISO 9001, API |

| NeoNickel | UK | Custom fasteners | DNV, Lloyds |

| Penn Engineering | USA | High-strength | NAS, MIL-SPEC |

| Nippon Steel | Japan | Precision bolts | JIS, ISO |

Cost Breakdown Factors

Components affecting final bolt pricing:

| Cost Component | Percentage | Variables |

|---|---|---|

| Raw Material | 45-60% | Nickel market price |

| Manufacturing | 25-35% | Size, quantity, complexity |

| Testing/Cert | 10-15% | ASTM/NACE requirements |

| Profit Margin | 15-25% | Supplier positioning |

Procurement Considerations

Key purchasing factors for Hastelloy bolts:

| Consideration | Options | Cost Impact |

|---|---|---|

| Quantity | 1-50: +30% 50-500: Base 500+: -15% |

High volume discounts |

| Lead Time | Standard: 8-12 weeks Expedited: 4-6 weeks |

+50-100% for rush |

| Certifications | Basic: Mill certs Full: NACE MR0175 |

+15-30% for full certs |

| Packaging | Bulk: Standard VCI: +10% Indiv: +25% |

Special packaging adds cost |

Regional Market Variations

Geographical price differences (C276 M12 example):

| Region | Price Range | Factors |

|---|---|---|

| North America | $22-$40 | Mature supply chain |

| Europe | €25-€45 | Higher labor costs |

| Middle East | $30-$50 | Import duties |

| Asia | $15-$30 | Lower labor costs |

Related Questions

Why are Hastelloy C276 bolts more expensive than stainless steel 316 bolts?

Hastelloy C276 bolts cost 5-8 times more than 316 stainless due to their high nickel content (52-62%), specialized manufacturing processes, and superior corrosion resistance in extreme environments like hydrochloric acid service or seawater applications.

What certifications should I look for when purchasing Hastelloy bolts?

Key certifications include ASTM B574 (material standard), NACE MR0175 for sour service, PED 2014/68/EU for pressure equipment, and manufacturer’s test reports showing chemical analysis and mechanical properties verification.

How can I verify the authenticity of Hastelloy bolts?

Authentic Hastelloy bolts should have proper mill test reports, visible heat numbers on each bolt, PMI (positive material identification) verification available, and come from authorized distributors with traceable documentation back to the original manufacturer.