The pricing of Hastelloy C-series alloys (including C276, C22, C2000, and C-4) fluctuates based on nickel market dynamics, manufacturing processes, and global demand. This comprehensive guide examines current price structures across product forms, analyzes key cost drivers, and provides procurement strategies for these premium corrosion-resistant alloys used in chemical processing, pollution control, and oil/gas industries.

Current Market Prices by Product Form (2024)

Price ranges for common Hastelloy C-series products:

| Alloy | Sheet/Plate ($/kg) | Bar Stock ($/kg) | Pipe/Tube ($/kg) | Wire ($/kg) |

|---|---|---|---|---|

| C276 | $45-$65 | $50-$75 | $60-$90 | $70-$110 |

| C22 | $50-$70 | $55-$80 | $65-$95 | $75-$120 |

| C2000 | $60-$85 | $65-$90 | $75-$110 | $85-$130 |

| C-4 | $40-$60 | $45-$70 | $55-$85 | $65-$100 |

Note: Prices reflect standard sizes in commercial quantities (100+ kg), with 20-40% premium for small orders or special dimensions.

Key Price Determinants

Factors influencing Hastelloy C-series pricing:

| Factor | Impact Range | Details |

|---|---|---|

| Nickel Prices | 50-60% of cost | LME nickel price fluctuations |

| Molybdenum Prices | 15-20% of cost | Critical alloying element |

| Manufacturing Process | ±25% variance | VIM vs. ESR melting methods |

| Product Form | 30-50% spread | Wire vs. plate cost differences |

| Certifications | +10-30% | NACE, PED, nuclear grades |

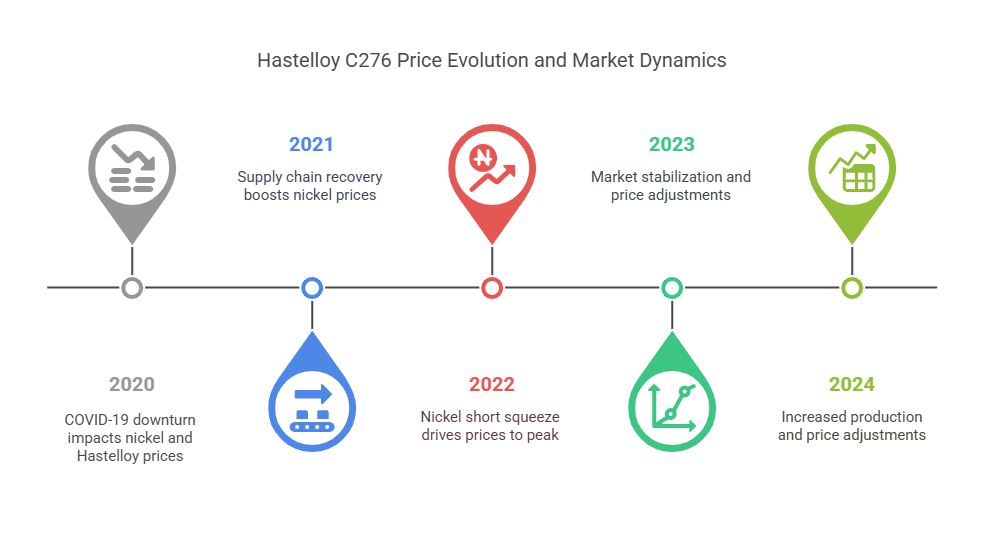

Historical Price Trends

Five-year price movement for Hastelloy C276:

| Year | Avg Plate Price ($/kg) | Nickel Price ($/mt) | Market Conditions |

|---|---|---|---|

| 2020 | $35-$45 | $13,000 | COVID downturn |

| 2021 | $40-$50 | $18,000 | Supply chain recovery |

| 2022 | $55-$75 | $25,000 | Nickel short squeeze |

| 2023 | $50-$70 | $21,000 | Market stabilization |

| 2024 | $45-$65 | $17,000 | Increased production |

Regional Price Variations

Geographical price differences for C276 plate:

| Region | Price Range ($/kg) | Key Factors |

|---|---|---|

| North America | $45-$65 | Domestic production |

| Europe | €50-€70 | Import costs |

| Asia | $40-$60 | Lower labor costs |

| Middle East | $55-$75 | Project-driven demand |

Price Comparison to Alternatives

Relative cost of corrosion-resistant alloys:

| Material | Price Relative to C276 | Corrosion Resistance |

|---|---|---|

| 316L Stainless | 15-20% | Moderate |

| Alloy 20 | 40-50% | Good |

| Inconel 625 | 80-90% | Excellent |

| Titanium Gr2 | 120-150% | Excellent (different) |

Procurement Strategies

Cost optimization approaches:

| Strategy | Potential Savings | Considerations |

|---|---|---|

| Volume Contracts | 10-20% | Annual commitments |

| Standard Sizes | 15-30% | Avoids custom milling |

| Local Sourcing | 5-15% | Reduces logistics |

| Secondary Alloys | 20-40% | With proper certification |

Related Questions

Why is Hastelloy C22 more expensive than C276?

Hastelloy C22 typically costs 5-15% more than C276 due to its higher chromium content (20-22.5% vs 14.5-16.5%) and optimized chemistry that provides better performance in oxidizing environments, justifying the premium for critical applications.

How often do Hastelloy prices change?

Hastelloy prices typically adjust quarterly based on nickel market fluctuations, though major suppliers may issue price adjustments more frequently during periods of high metal price volatility (monthly or even weekly during market disruptions).

Can I get discounts for large Hastelloy orders?

Yes, most suppliers offer volume discounts of 10-25% for orders exceeding 1,000 kg, with additional negotiation possible for multi-ton purchases or long-term contracts, especially when timed during lower nickel price periods.