Hastelloy C22 and C276 are two of the most widely used nickel-chromium-molybdenum superalloys in corrosive environments. Both alloys offer exceptional resistance to a wide range of aggressive chemicals, making them popular choices for chemical processing, pollution control, and other demanding applications. This article provides an in-depth comparison of these two high-performance alloys, examining their chemical compositions, mechanical properties, corrosion resistance, and typical applications.

Chemical Composition Comparison

The primary difference between Hastelloy C22 and C276 lies in their chemical compositions:

| Element | Hastelloy C22 (%) | Hastelloy C276 (%) |

|---|---|---|

| Nickel | 56 (min) | 52 (min) |

| Chromium | 20.0-22.5 | 14.5-16.5 |

| Molybdenum | 12.5-14.5 | 15.0-17.0 |

| Tungsten | 2.5-3.5 | 3.0-4.5 |

| Iron | 2.0-6.0 | 4.0-7.0 |

| Cobalt | ≤2.5 | ≤2.5 |

Key differences: C22 has higher chromium content but slightly lower molybdenum compared to C276. The increased chromium in C22 provides better resistance to oxidizing environments, while C276’s higher molybdenum content enhances resistance to reducing acids.

Corrosion Resistance Comparison

Both alloys offer excellent corrosion resistance, but with some notable differences:

| Environment | Hastelloy C22 Performance | Hastelloy C276 Performance |

|---|---|---|

| Pitting Resistance | Excellent (PREN ≈ 68) | Excellent (PREN ≈ 69) |

| Crevice Corrosion | Superior resistance | Very good resistance |

| Oxidizing Media | Better performance | Good performance |

| Reducing Acids | Good resistance | Slightly better resistance |

| Chloride Stress Corrosion | Highly resistant | Highly resistant |

Notable advantage: C22 demonstrates superior performance in environments containing oxidizing chlorides and other oxidizing media due to its higher chromium content. C276 performs slightly better in pure reducing acid environments.

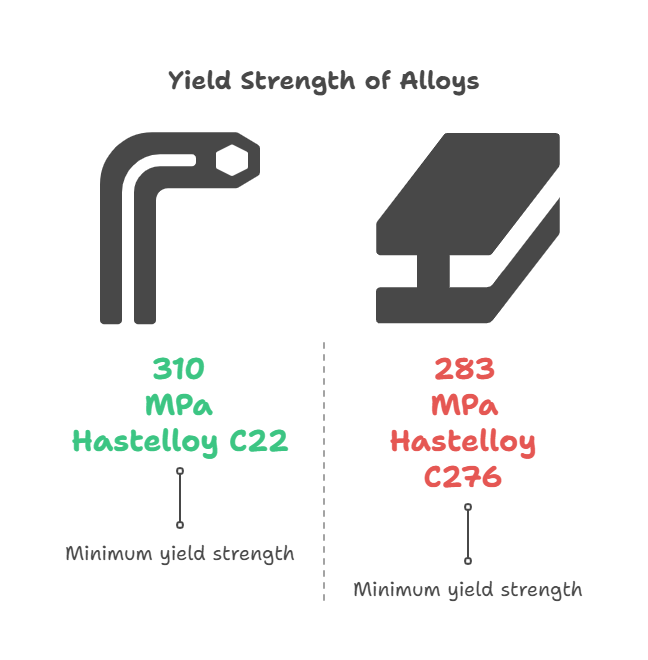

Mechanical Properties

The mechanical properties of these alloys at room temperature:

| Property | Hastelloy C22 | Hastelloy C276 |

|---|---|---|

| Tensile Strength (MPa) | 690 min | 690 min |

| Yield Strength (MPa) | 310 min | 283 min |

| Elongation (%) | 40 min | 40 min |

| Hardness (Rockwell B) | ≤100 | ≤100 |

Key point: While both alloys have similar mechanical properties, C22 typically shows slightly higher yield strength values in practice due to its optimized composition.

Temperature Capabilities

Both alloys maintain good mechanical properties at elevated temperatures:

| Temperature Range | Hastelloy C22 | Hastelloy C276 |

|---|---|---|

| Continuous Service | Up to 600°C (1112°F) | Up to 593°C (1100°F) |

| Short-term Service | Up to 1040°C (1904°F) | Up to 1038°C (1900°F) |

Important note: Both alloys should not be used in sulfur-bearing environments above 540°C (1000°F) due to potential embrittlement issues.

Fabrication and Welding Characteristics

The fabrication characteristics of these alloys:

| Process | Hastelloy C22 | Hastelloy C276 |

|---|---|---|

| Hot Working | 1150-1200°C (2100-2200°F) | 1120-1200°C (2050-2200°F) |

| Cold Working | Excellent workability | Good workability |

| Welding | Excellent weldability | Excellent weldability |

| Post-Weld Heat Treatment | Generally not required | Generally not required |

Fabrication advantage: C22 is generally considered slightly easier to work with due to its optimized composition, particularly in welding applications where it shows less susceptibility to hot cracking.

Typical Applications

The common applications for each alloy:

| Industry | Hastelloy C22 Applications | Hastelloy C276 Applications |

|---|---|---|

| Chemical Processing | Reactors, scrubbers, heat exchangers | Reactors, columns, piping systems |

| Pollution Control | Flue gas desulfurization systems | Waste incineration systems |

| Pharmaceutical | High-purity systems | Process equipment |

| Oil & Gas | Downhole components | Offshore platform components |

Application guidance: C22 is often preferred for new designs where maximum corrosion resistance is required, while C276 remains popular for legacy systems and applications where its long-term performance is well documented.

Cost Considerations

The cost factors between these alloys:

| Factor | Hastelloy C22 | Hastelloy C276 |

|---|---|---|

| Material Cost | Typically 5-15% higher | Slightly lower |

| Availability | Widely available | Extremely available |

| Lifecycle Cost | Potentially lower in aggressive environments | Proven long-term performance |

Cost-benefit analysis: While C22 commands a premium price, its superior performance in many environments can lead to lower total lifecycle costs in demanding applications.

Related Questions

Which is better for seawater applications, Hastelloy C22 or C276?

Both alloys perform well in seawater, but Hastelloy C22 generally offers better resistance to crevice corrosion in chloride-containing environments like seawater. Its higher chromium content provides superior protection against localized corrosion in marine applications.

Can Hastelloy C276 be used as a direct replacement for C22?

While C276 can sometimes replace C22, it’s not always a direct substitute. C22’s superior resistance to oxidizing environments means it may perform better in certain applications. A thorough evaluation of the specific service environment is recommended before substitution.

How do Hastelloy C22 and C276 compare to stainless steels in terms of corrosion resistance?

Both C22 and C276 far surpass standard stainless steels (even super austenitic grades) in corrosion resistance, particularly in aggressive chloride environments and reducing acid conditions. Their nickel-chromium-molybdenum-tungsten compositions provide protection in environments where stainless steels would rapidly corrode.