Hastelloy C276 is a nickel-molybdenum-chromium alloy designed for extreme corrosion resistance, especially in reducing and mixed environments. A professional C276 plate factory usually has melting, hot-rolling, heat-treatment and precision-cutting capabilities to ensure stable mechanical properties and uniform structure. Plates are commonly used in chemical plants, exhaust-gas treatment systems, seawater equipment, reactor vessels, and high-temperature corrosive service.

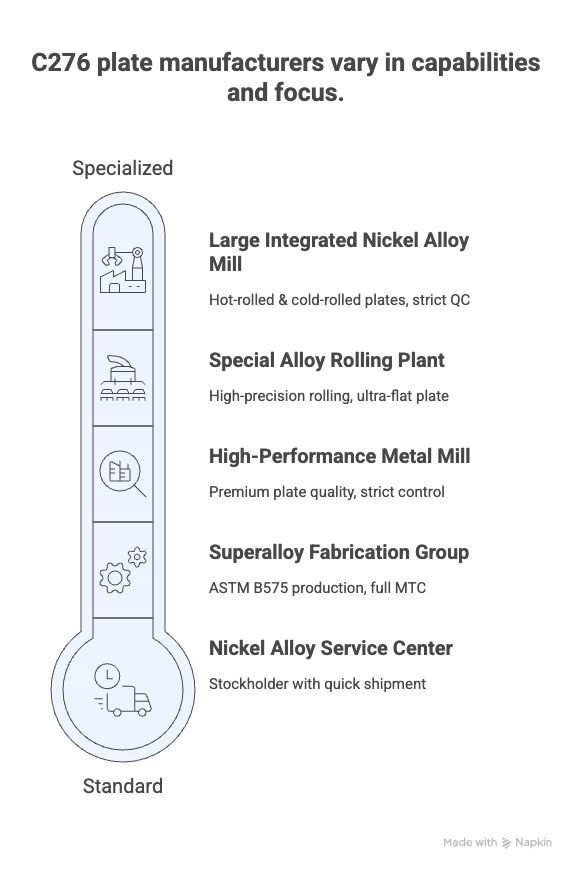

Main C276 Plate Manufacturers

| Factory | Region | Capabilities |

|---|---|---|

| Large Integrated Nickel Alloy Mill | China | Hot-rolled & cold-rolled plates, cut-to-size, strict QC, fast delivery for export projects. |

| Special Alloy Rolling Plant | China | High-precision rolling, ultra-flat plate, customized heat treatment. |

| Superalloy Fabrication Group | India | ASTM B575 production, full MTC, thickness up to 100 mm. |

| Nickel Alloy Service Center | Middle East | Stockholder with quick shipment, polishing & surface finishing available. |

| High-Performance Metal Mill | Europe | Premium plate quality, strict dimensional control, used in petrochemical projects. |

Typical C276 Plate Sizes

| Specification | Typical Range |

|---|---|

| Thickness | 0.3 mm – 120 mm |

| Width | 1000 mm – 2500 mm |

| Length | 2000 mm – 6000 mm (customizable) |

| Standard | ASTM B575 / ASME SB575 |

| Surface | 2B, No.4, bright-annealed, polished |

Factory Price Range

| Thickness | Typical Factory Price (USD/kg) |

|---|---|

| 0.5–3 mm | ≈ 45 – 55 USD/kg |

| 3–10 mm | ≈ 48 – 60 USD/kg |

| 10–30 mm | ≈ 50 – 65 USD/kg |

| 30–60 mm | ≈ 55 – 70 USD/kg |

| >60 mm | Custom quotation based on size & heat treatment |

Quality Control in a C276 Plate Factory

- Vacuum melting or ESR for purity and low inclusions

- Solution annealing to ensure corrosion resistance

- Ultrasonic testing for plate integrity

- Mechanical testing: tensile, yield, elongation

- Full chemical composition analysis

- Heat-number traceability

Applications of C276 Plate

| Industry | Application |

|---|---|

| Chemical Processing | Reactor wall plates, acid pipeline systems |

| Pollution Control | Scrubber components, flue-gas equipment |

| Marine & Offshore | Corrosion-resistant structural parts |

| Pharmaceutical & Pulp | High-purity tanks and vessels |

| Energy & Power | Heat-exchanger shell plates |

How to Select a Reliable Factory

- Check if the mill can produce according to ASTM B575

- Confirm they can provide complete MTC and testing reports

- Evaluate thickness tolerance and flatness control

- Ask about rolling method (hot-rolled / cold-rolled)

- Confirm export-grade packaging and delivery time