Hastelloy C276 sheet is a premium nickel‑molybdenum‑chromium alloy with outstanding corrosion resistance across a wide range of aggressive environments, including reducing, oxidizing, and chlorinated media. Because of these properties, Hastelloy C276 sheet is widely used in chemical processing, pollution control, marine engineering, oil & gas, and power generation industries. Choosing a reliable supplier is crucial to ensure material quality, traceability, and certification support. In this article, we explore Hastelloy C276 sheet properties, applications, and top suppliers in the market.

What Is Hastelloy C276 Sheet?

Hastelloy C276 is a nickel‑based corrosion‑resistant alloy combining molybdenum, chromium, and iron. This unique chemistry gives exceptional resistance to pitting, crevice corrosion, and stress corrosion cracking in harsh environments such as sulfuric, phosphoric, and hydrochloric acids. The sheet form allows the material to be used for fabrications such as tanks, liners, cladding, and flanges where flat stock is needed for forming or welding.

Key Properties of Hastelloy C276 Sheet

| Property | Performance Benefit |

| Corrosion Resistance | Excellent in reducing and oxidizing environments |

| Stress Corrosion Cracking Resistance | Superior resistance in chloride‑containing environments |

| Pitting & Crevice Corrosion | High resistance over wide temperature ranges |

| Fabricability | Good for forming, welding, and machining |

| Heat Resistance | Stable at high service temperatures |

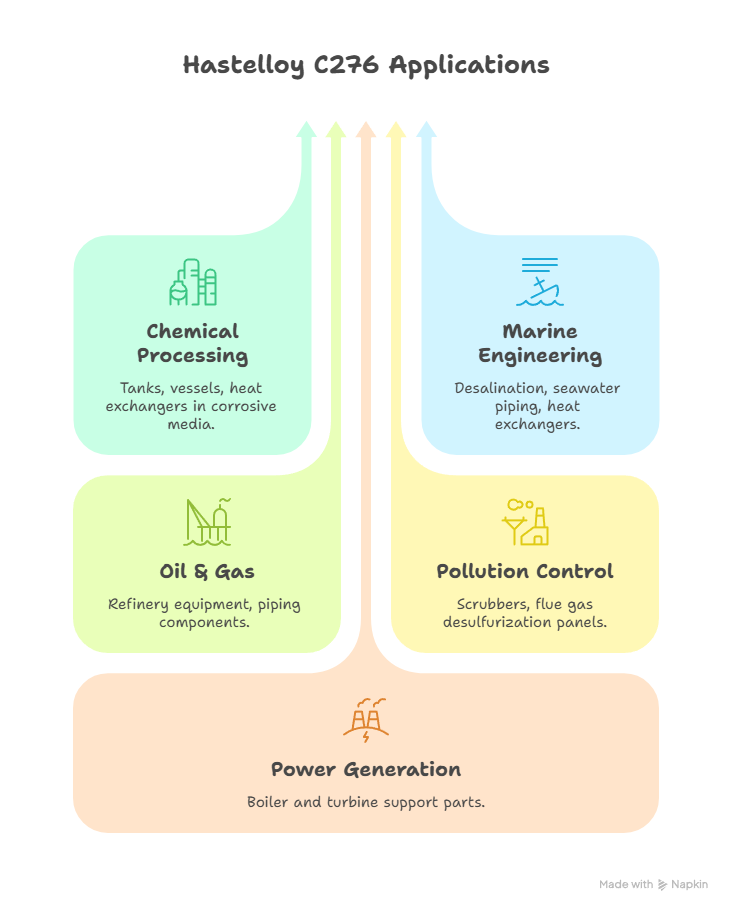

Common Applications of Hastelloy C276 Sheet

Hastelloy C276 sheet is ideal for applications exposed to corrosive chemicals, seawater, and mixed environments that would attack standard steels and alloys.

| Industry | Typical Use |

| Chemical Processing | Tanks, vessels, heat exchanger panels |

| Marine Engineering | Desalination equipment, seawater piping, heat exchangers |

| Oil & Gas | Refinery process equipment, piping components |

| Pollution Control | Scrubbers, flue gas desulfurization panels |

| Power Generation | Boiler and turbine support parts |

Supplier Selection Criteria

When selecting a supplier for Hastelloy C276 sheet, consider quality, certification, material traceability, stock availability, and support services like cutting and processing.

| Selection Factor | Why It Matters |

| Material Certification | Ensures alloy meets ASTM/ASME standards with full traceability |

| Available Inventory | Reduces lead time; ready stock of thicknesses and sizes |

| Customization Services | Cut‑to‑length, edge preparation, precision sizing |

| Technical Support | Material selection and fabrication guidance |

| Delivery & Logistics | Reliable shipping and documentation for global projects |

Top Hastelloy C276 Sheet Suppliers

Below are reputable suppliers and manufacturers of Hastelloy C276 sheet that provide certified material and support services:

- Ncalloys: Ncalloys is a trusted supplier of Hastelloy C276 sheets, offering a full range of thicknesses, sizes, and custom cutting services. Materials are provided with complete certification and quality assurance for chemical processing, marine, and industrial applications. Contact [email protected] for a quote and technical support.

- Haynes International: A leading producer of corrosion‑resistant alloys, including Hastelloy C276. They offer sheet products with full traceability and global supply support.

- Special Metals: Known for high‑performance superalloys, Special Metals supplies Hastelloy C276 sheets with industry certifications and quality documentation suitable for critical service environments.

- Rolled Alloys: Rolled Alloys stocks Hastelloy C276 sheet in various thicknesses and sizes, providing rapid delivery and customer support for fabrication and engineering projects.

- Vallourec & Mannesmann Stainless Tubes (VMST): A global supplier of alloy sheets and plates, offering Hastelloy C276 with a comprehensive inventory and distribution network for international projects.

Available Sheet Sizes and Thicknesses

Hastelloy C276 sheet is typically provided in a range of thicknesses and flat sizes to suit various fabrication and welding requirements. Common offerings include:

| Thickness | Typical Use |

| 0.5 – 3 mm | Thin panels and liners |

| 4 – 10 mm | Process equipment panels, fabricated parts |

| 10 – 25 mm | Heavy corrosion‑resistant structures |

| Custom Thickness | Special engineering requirements |

Why Choose Hastelloy C276 Sheet

Hastelloy C276 sheet combines corrosion resistance, fabricability, and long service life, making it ideal for environments where mixed corrosion, chlorides, and elevated temperatures are present. Its versatility and durability set it apart from many stainless steels and ordinary nickel alloys.

Related Questions

1. What industries commonly use Hastelloy C276 sheet?

Hastelloy C276 sheet is widely used in chemical processing, marine engineering, pollution control, oil & gas, and power generation due to its resistance to corrosive environments.

2. Can Hastelloy C276 sheet be welded?

Yes, Hastelloy C276 sheet is weldable using standard nickel‑based filler metals and common welding processes; proper procedures ensure minimal distortion and excellent joint integrity.

3. How do I request a quote for Hastelloy C276 sheets?

You can contact a supplier like Ncalloys at [email protected] with your required dimensions, thicknesses, and certification needs to receive a tailored quotation.