Hastelloy C276 springs command premium pricing due to the alloy’s exceptional corrosion resistance and high nickel content. The price for these specialized springs varies significantly based on quantity, size, design complexity, and market conditions. This article examines the key factors influencing Hastelloy C276 spring costs, provides typical price ranges, and offers guidance for procurement.

Price Range Overview

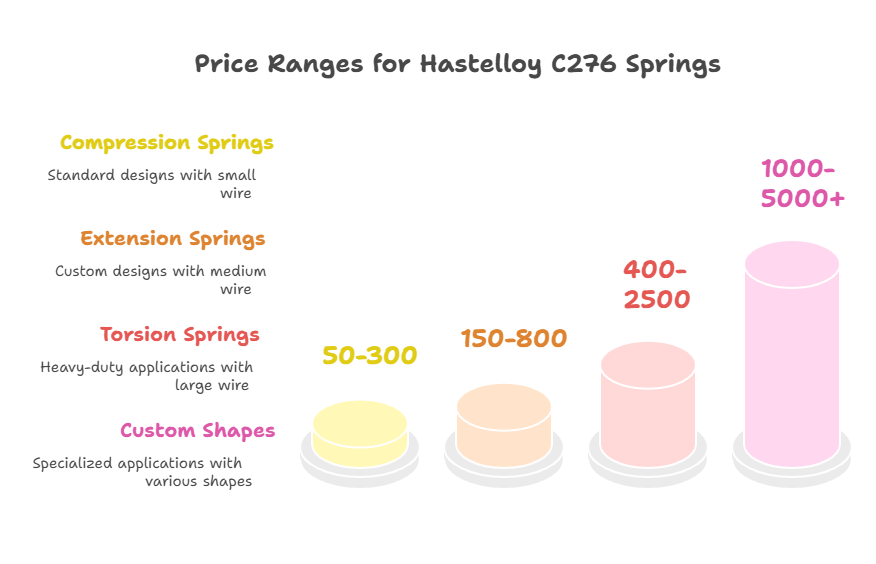

Current market prices for Hastelloy C276 springs (2024):

| Spring Type | Size Range | Price Range (USD) | Notes |

|---|---|---|---|

| Compression Springs | Small (0.5-5mm wire) | $50-$300 each | Standard designs |

| Extension Springs | Medium (5-15mm wire) | $150-$800 each | Custom designs |

| Torsion Springs | Large (15-30mm wire) | $400-$2,500 each | Heavy-duty applications |

| Custom Shapes | Various | $1,000-$5,000+ | Specialized applications |

Note: Prices can fluctuate ±20% based on nickel market prices and manufacturing complexity.

Key Price Factors

Major elements affecting Hastelloy C276 spring pricing:

| Factor | Price Impact | Details |

|---|---|---|

| Material Costs | High (40-60% of total) | Nickel price volatility directly affects costs |

| Wire Diameter | Exponential increase | Thicker wire requires more material and energy |

| Quantity | Volume discounts | Orders >100 units typically get 15-30% discount |

| Surface Finish | 10-50% premium | Electropolishing or special coatings add cost |

| Tolerances | Up to 100% more | Precision aerospace specs cost significantly more |

Manufacturing Process Costs

Breakdown of production cost components:

| Process Step | Cost Contribution | Challenges with C276 |

|---|---|---|

| Wire Production | 25-35% | Specialized nickel alloy drawing |

| Spring Forming | 30-40% | Hard material requires premium tooling |

| Heat Treatment | 15-25% | Precise temperature control needed |

| Testing/QA | 10-20% | Extensive corrosion testing often required |

Regional Price Variations

Geographical differences in pricing:

| Region | Price Premium | Reasons |

|---|---|---|

| North America | Base Price | Mature supply chain |

| Europe | +10-15% | Higher labor costs |

| Asia | -15-30% | Lower labor but quality varies |

| Middle East | +20-40% | Import costs for oil/gas projects |

Cost Comparison to Alternatives

Relative pricing to other materials:

| Material | Price Relative to C276 | Corrosion Resistance |

|---|---|---|

| 316 Stainless | 15-20% of C276 | Moderate |

| Alloy 20 | 40-50% of C276 | Good |

| Hastelloy C22 | 90-110% of C276 | Excellent |

| Titanium | 120-150% of C276 | Excellent (different profile) |

Procurement Strategies

Ways to optimize Hastelloy C276 spring purchases:

| Strategy | Potential Savings | Considerations |

|---|---|---|

| Consolidated Orders | 15-25% | Reduces setup charges |

| Standard Designs | 20-40% | Avoids custom tooling |

| Long-term Contracts | 10-15% | Locks in material prices |

| Alternative Finishes | 5-15% | May affect performance |

Related Questions

Why are Hastelloy C276 springs so expensive compared to stainless steel?

Hastelloy C276 springs cost significantly more due to the high nickel content (52-62%) in the alloy, specialized manufacturing processes required for nickel alloys, and the material’s premium corrosion-resistant properties that justify the price in demanding applications.

How often do Hastelloy C276 spring prices change?

Prices typically adjust quarterly based on nickel market fluctuations, but can change more frequently during periods of high metal price volatility. Most manufacturers offer price protection for 30-90 days on quotes.

Can you get cheaper Hastelloy C276 springs from overseas suppliers?

While Asian suppliers may offer 15-30% lower prices, quality consistency, lead times, and import duties often offset apparent savings. For critical applications, certified domestic suppliers usually provide better value despite higher initial costs.