Hastelloy refers to a family of high‑performance nickel‑based alloys known for exceptional corrosion resistance, oxidation stability, and mechanical strength in harsh environments. These properties make Hastelloy alloys indispensable in chemical processing, marine engineering, power generation, oil & gas, and pollution control. Choosing the right Hastelloy suppliers is essential to ensure material quality, traceability, certification, and reliable delivery for critical applications. This article provides an overview of Hastelloy alloy types, key applications, and leading suppliers worldwide.

What Is Hastelloy?

Hastelloy is a trademarked group of nickel alloys that contain chromium, molybdenum, iron, and other elements to deliver outstanding corrosion resistance. Different grades — such as Hastelloy C‑276, C‑22, B‑2, B‑3, and others — are tailored for specific environments, including reducing acids, oxidizing acids, chloride‑rich conditions, and extreme temperatures.

Common Hastelloy Grades and Their Uses

| Hastelloy Grade | Primary Features | Typical Use |

|---|---|---|

| C‑276 | Excellent all‑around corrosion resistance | Tanks, piping, heat exchangers |

| C‑22 | Advanced resistance to pitting and crevice corrosion | Severe chemical environments |

| B‑2 | Excellent resistance to hydrochloric acid | Acid processing equipment |

| B‑3 | Enhanced resistance in reducing environments | Specialized acid applications |

| C‑2000 | High strength and chloride resistance | Oil & gas, marine systems |

Key Applications for Hastelloy Alloys

| Industry | Application Examples |

|---|---|

| Chemical Processing | Reactors, vessels, piping, heat exchangers |

| Marine & Offshore | Seawater handling systems, desalination |

| Oil & Gas | Sour service, acid gas environments |

| Power Generation | Boilers, turbines, condensers |

| Pollution Control | Scrubbers, flue gas desulfurization systems |

Why Choosing a Reputable Hastelloy Supplier Matters

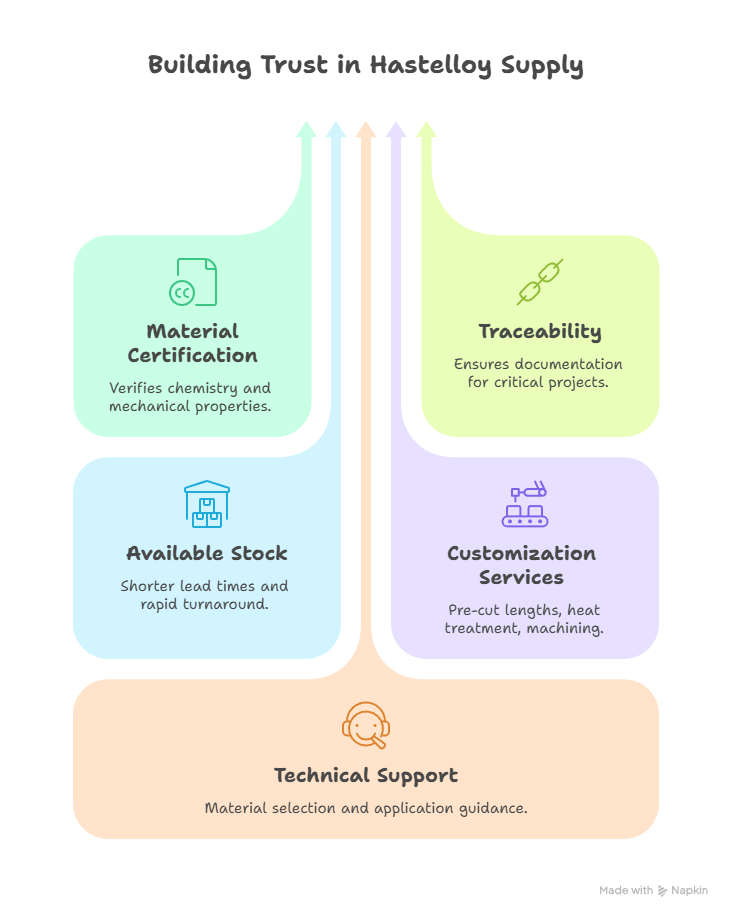

High‑performance materials like Hastelloy must meet stringent standards to ensure corrosion resistance and structural integrity. Reliable suppliers provide:

| Supplier Capability | Importance |

|---|---|

| Full Material Certification | Verifies chemistry and mechanical properties |

| Traceability | Ensures documentation for critical projects |

| Available Stock | Shorter lead times and rapid turnaround |

| Customization Services | Pre‑cut lengths, heat treatment, machining |

| Technical Support | Material selection and application guidance |

Leading Hastelloy Suppliers

Below are reputable global suppliers and manufacturers of Hastelloy alloys that provide certified material for industrial needs:

- Ncalloys: Ncalloys is a trusted supplier of Hastelloy alloys such as C‑276, C‑22, B‑2, and B‑3 in sheets, plates, tubes, bars, and custom fabricated components. We offer full certifications, traceability, and technical support for chemical, marine, and industrial applications. Contact [email protected] for quotes and specifications.

- Haynes International: A global leader in high‑performance nickel alloys, Haynes International produces a wide range of Hastelloy grades with full quality documentation and international supply networks.

- Special Metals (AMETEK): Provides Hastelloy materials with rigorous testing and certifications. Known for precision quality and reliability for critical applications.

- Rolled Alloys: Stocks a broad selection of Hastelloy bars, sheets, and tubes with competitive delivery times and customer service for fabrication projects.

- Vallourec & Mannesmann Stainless Tubes (VMST): A global supplier of specialty alloys including Hastelloy, offering various forms and sizes with strong inventory and logistics support.

- Future Metals: A distributor of high‑performance alloys with global reach, offering Hastelloy C‑276, C‑22, and other grades with fast delivery and custom processing services.

- Acme Metals: Offers Hastelloy alloy products with comprehensive stock and fabrication services including cutting, machining, and heat treatment.

How to Request Hastelloy Material

When requesting material from Hastelloy suppliers, make sure to provide:

| Information Needed | Purpose |

| Alloy Grade | Selects appropriate corrosion and temperature performance |

| Product Form (sheet, tube, bar) | Affects manufacturing process and cost |

| Dimensions & Tolerance | Ensures fit for fabrication or assembly |

| Certifications Required | Verifies compliance to ASTM/ASME/ISO standards |

| Quantity and Delivery Schedule | Determines pricing and lead time |

Related Questions

1. What is the most corrosion‑resistant Hastelloy grade?

Hastelloy C‑22 is generally the most resistant to pitting and crevice corrosion among common Hastelloy grades, especially in mixed environments.

2. Can Hastelloy alloys be welded?

Yes, Hastelloy alloys are weldable using appropriate nickel‑based filler metals; proper procedures ensure integrity and corrosion resistance across the weld.

3. How does Hastelloy compare with stainless steel?

Hastelloy alloys typically outperform stainless steels in severe corrosive environments, especially with reducing acids and chloride exposure.