Hastelloy and Inconel are two high-performance nickel-based alloys widely used in chemical processing, aerospace, marine, and industrial applications. Both offer excellent corrosion resistance and mechanical strength, but they are designed for different environments. Understanding their differences is essential for selecting the right alloy for high-stress, high-temperature, or corrosive conditions.

Overview of Hastelloy

Hastelloy is a family of nickel-molybdenum alloys designed for superior corrosion resistance in highly aggressive chemical environments. Common grades include Hastelloy C-22, C-276, and B-2. These alloys resist strong oxidizers, reducing agents, and a wide range of acids, making them ideal for chemical reactors, marine environments, and wastewater treatment equipment.

Overview of Inconel

Inconel is a family of nickel-chromium-based superalloys that maintain high strength, oxidation resistance, and mechanical stability at elevated temperatures. Common grades include Inconel 600, 625, and 718. Inconel is widely used in aerospace engines, turbines, chemical plants, and marine equipment where high-temperature performance and corrosion resistance are required.

Chemical Composition Comparison

| Property | Hastelloy (C-276) | Inconel (625) |

|---|---|---|

| Nickel (Ni) | 57 min | 58 min |

| Chromium (Cr) | 14.5–16.5 | 20–23 |

| Molybdenum (Mo) | 15–17 | 8–10 |

| Iron (Fe) | 5 max | ≤5 |

| Cobalt (Co) | ≤2 | ≤1 |

| Carbon (C) | ≤0.08 | ≤0.10 |

| Other Elements | Tungsten, Manganese, Silicon traces | Niobium + Tantalum |

Mechanical Properties Comparison

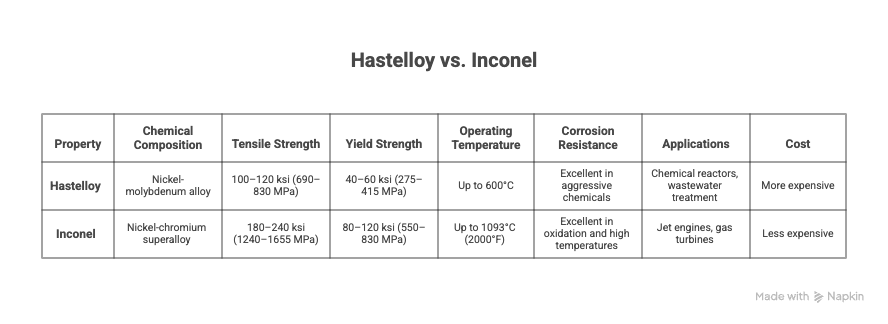

While both alloys offer good strength and corrosion resistance, their mechanical behavior differs:

| Property | Hastelloy C-276 | Inconel 625 |

|---|---|---|

| Tensile Strength | ≈ 100–120 ksi (690–830 MPa) | ≈ 180–240 ksi (1240–1655 MPa) |

| Yield Strength | ≈ 40–60 ksi (275–415 MPa) | ≈ 80–120 ksi (550–830 MPa) |

| Elongation | ≈ 35–40% | ≈ 30–50% |

| Operating Temperature | Up to 600°C | Up to 1093°C (2000°F) |

Corrosion Resistance

Both alloys are corrosion-resistant, but their strengths differ by environment:

– Hastelloy: Exceptional resistance to oxidizing and reducing acids, strong chemical environments, and seawater. Excellent choice for highly aggressive chemical processes.

– Inconel: Excellent resistance to oxidation, high temperatures, and moderate chemical exposure. More suitable for high-temperature environments and marine equipment under stress.

Applications Comparison

Hastelloy and Inconel are used in different industries based on their strengths:

Hastelloy: Chemical reactors, acid storage tanks, wastewater treatment equipment, marine equipment in aggressive chemical exposure.

Inconel: Jet engine components, gas turbines, heat exchangers, chemical processing equipment under high temperatures, and marine pumps.

Key Differences

– Temperature Performance: Inconel withstands higher temperatures than Hastelloy, making it ideal for aerospace and turbine applications.

– Corrosion Resistance: Hastelloy excels in highly corrosive chemical environments; Inconel excels in oxidizing and high-temperature conditions.

– Mechanical Strength: Inconel 625 generally has higher tensile and yield strength, particularly at elevated temperatures.

– Cost Consideration: Hastelloy is often more expensive due to high molybdenum content and corrosion resistance in aggressive chemicals.

Related Questions

Which is better for chemical corrosion, Hastelloy or Inconel?

Hastelloy is superior for chemical corrosion, especially in strong acids, oxidizers, and reducing environments.

Which alloy performs better at high temperatures?

Inconel is better suited for high-temperature applications such as jet engines and turbines.

Can both Hastelloy and Inconel be welded?

Yes, both alloys can be welded using specialized techniques, but Hastelloy requires more careful welding procedures due to its high molybdenum content.