Hastelloy and Inconel are two prominent families of high-performance nickel-based alloys used in corrosive, high-temperature, and demanding industrial environments. While both offer superior corrosion resistance and strength compared with many other materials, Hastelloy alloys generally carry a higher price tag than Inconel alloys. This price difference results from alloy chemistry, manufacturing costs, performance capabilities, and application requirements. Understanding how Hastelloy and Inconel pricing compares—and the factors affecting cost—can help engineers, buyers, and procurement teams make informed material choices.

Overview of Hastelloy and Inconel

Hastelloy refers to a family of nickel-chromium-molybdenum alloys (e.g., C276, C22, X) engineered for exceptional corrosion resistance in aggressive chemical environments, including strong acids and mixed corrosive media.

Inconel refers to a group of nickel-chromium alloys (e.g., 600, 625, 718) designed for a balance of corrosion resistance, mechanical strength, and high temperature performance.

Typical Price Comparison

In most markets, **Hastelloy alloys are priced higher than Inconel alloys** due to their more complex alloying content and broader corrosion resistance capabilities. Below is a general comparison across common product forms such as pipes, plates, and bar stock:

| Material | Typical Relative Price Level | Price Influence |

|---|---|---|

| Inconel (e.g., 625) | Moderate | High nickel content and balanced performance |

| Inconel (e.g., 718) | Moderate to High | Precipitation-hardened, aerospace use |

| Hastelloy C276 | High | High molybdenum and chromium for extreme corrosion resistance |

| Hastelloy C22 | Very High | Optimized for highly aggressive mixed acid environments |

On a broad scale, material cost levels often trend as follows (indicative ranges):

• Inconel alloys—**lower to moderate cost**

• Hastelloy alloys—**high to very high cost**

Examples of Price Levels by Product Form

The specific pricing of Hastelloy and Inconel varies by product form (e.g., pipe, sheet, plate, bar) and by manufacturer, but typical relative relationships include:

| Product Form | Inconel Typical Price | Hastelloy Typical Price |

|---|---|---|

| Pipe/Tubing (per kg) | $40 – $80 | $80 – $150+ |

| Sheet/Plate (per kg) | $38 – $75 | $75 – $160+ |

| Bar/Round (per kg) | $45 – $85 | $85 – $170+ |

These figures represent general industrial pricing ranges; actual quotes vary based on size, specification, finish, and order quantity. In many markets, Hastelloy products can cost **2× or more** than equivalent Inconel products, especially for high-alloy grades like C22 or C263.

Factors Influencing Hastelloy and Inconel Prices

Alloy Chemistry: Hastelloy alloys often contain higher percentages of costly elements such as molybdenum and chromium, increasing base material cost compared with Inconel. Higher nickel content alone also impacts price.

Performance Requirements: Hastelloy is designed for extreme corrosion resistance (e.g., strong acids, chloride environments), which requires stricter composition control and testing.

Manufacturing Complexity: Certain grades require specialized melting, forging, heat treatment, or finishing steps, which increase production cost.

Standards and Certification: ASTM/ASME compliance, NACE certification, or aerospace standards increase testing and documentation costs.

Surface Finish: Polished, pickled, or electropolished finishes add to material costs.

Order Quantity: Bulk purchasing often yields lower unit pricing, while small orders may have a cost premium.

Regional and Market Variations

Prices for Hastelloy and Inconel vary geographically due to labor costs, local supply chain factors, tariffs, and freight. For example:

• Factory pricing in low-cost manufacturing regions may seem lower, but landed cost (including shipping and duties) must be factored in.

• Distributor pricing in North America or Europe may be higher due to storage, testing, and certification overhead.

Application Considerations and Total Lifecycle Cost

Although Hastelloy has a higher upfront cost, its superior corrosion resistance can reduce maintenance, downtime, and replacement expenses over the long term, especially in aggressive chemical environments. In contrast, Inconel often represents a more cost-effective choice when corrosion demands are moderate and high mechanical strength or high-temperature capability is needed.

How to Choose Based on Price and Performance

Choose Inconel if:

• Corrosion conditions are moderate (e.g., seawater, oxidizing environments)

• Mechanical strength and temperature performance are critical

• Cost sensitivity is a key factor

Choose Hastelloy if:

• The service environment includes strong acids or mixed corrosion media

• Long service life and minimal maintenance are priorities

• Lifecycle cost outweighs initial material cost

Related Questions

Is Hastelloy always more expensive than Inconel?

Generally yes—Hastelloy alloys typically cost more because of their higher alloying content and advanced corrosion resistance design.

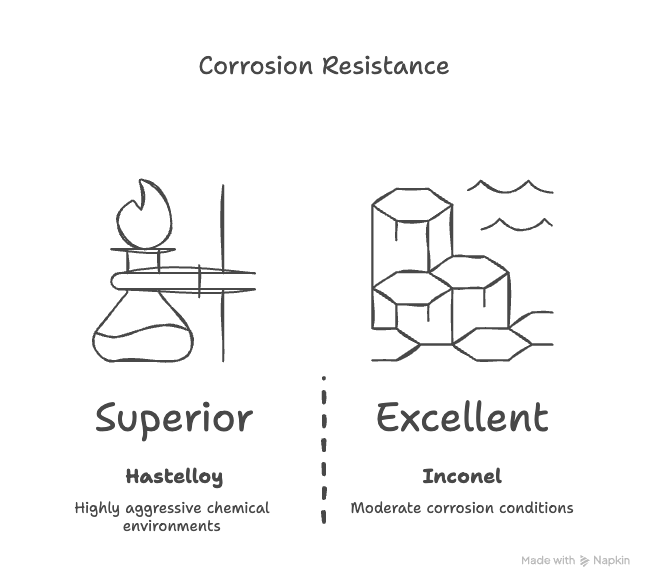

Which alloy offers better corrosion resistance?

Hastelloy usually provides superior corrosion resistance in highly aggressive chemical environments, while Inconel offers excellent resistance in a broader range of less aggressive conditions.

Can Inconel be substituted for Hastelloy to reduce cost?

Only in environments where corrosion demands are moderate. In highly corrosive conditions, Hastelloy’s performance may justify its higher price.