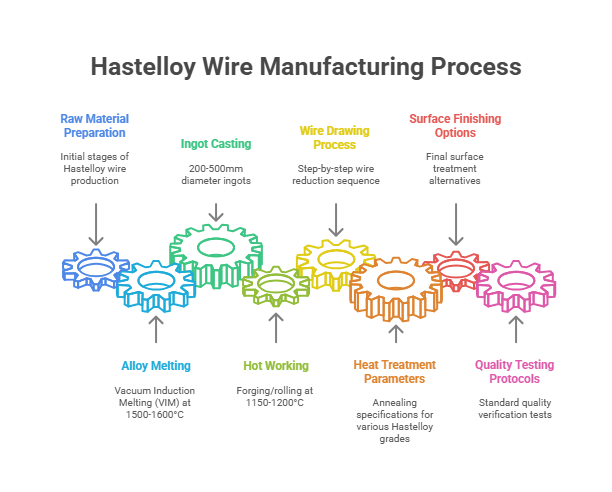

The production of Hastelloy wire is a specialized metallurgical process requiring precise control of composition, thermomechanical treatments, and surface finishing. This article details the complete manufacturing workflow for Hastelloy alloys (including C276, C22, B2, and X), from raw material selection to final wire products, highlighting the unique challenges of processing these high-performance nickel-based superalloys.

Raw Material Preparation

Initial stages of Hastelloy wire production:

| Process Step | Technical Parameters | Quality Control |

|---|---|---|

| Alloy Melting | Vacuum Induction Melting (VIM) at 1500-1600°C | Chemical analysis within ASTM B575 specs |

| Electroslag Remelting | Secondary refining process | Reduces inclusions and improves homogeneity |

| Ingot Casting | 200-500mm diameter ingots | Macro-etch testing for segregation |

| Hot Working | Forging/rolling at 1150-1200°C | Grain structure examination |

Critical factor: Maintaining precise control of molybdenum (15-17% for C276) and chromium (14.5-16.5% for C276) during melting is essential for achieving specified corrosion resistance properties.

Wire Drawing Process

Step-by-step wire reduction sequence:

| Stage | Diameter Reduction | Process Details |

|---|---|---|

| Rod Breakdown | 8mm → 5mm | Hot rolled then peeled |

| Intermediate Drawing | 5mm → 2mm | Lubricated dies, multi-pass |

| Fine Drawing | 2mm → 0.5mm | Diamond dies, controlled speed |

| Precision Drawing | 0.5mm → 0.1mm | Ultra-clean conditions |

Key challenges: Hastelloy’s work hardening rate requires frequent intermediate annealing (every 15-25% reduction) to maintain ductility and prevent cracking during drawing operations.

Heat Treatment Parameters

Annealing specifications for various Hastelloy grades:

| Alloy | Temperature Range | Atmosphere | Cooling Rate |

|---|---|---|---|

| C276 | 1065-1121°C | Hydrogen or Vacuum | Rapid (water quench) |

| C22 | 1038-1121°C | Hydrogen or Vacuum | Rapid (water quench) |

| B2 | 1038-1065°C | Hydrogen | Rapid (water quench) |

| X | 1177-1232°C | Hydrogen | Air cool |

Process control: Maintaining precise temperature uniformity (±10°C) during annealing is critical to prevent sensitization (chromium carbide precipitation) which would impair corrosion resistance.

Surface Finishing Options

Final surface treatment alternatives:

| Finish Type | Process Method | Surface Roughness (Ra) | Applications |

|---|---|---|---|

| Bright Annealed | Hydrogen atmosphere | 0.2-0.4μm | Medical, semiconductor |

| Pickled | Acid cleaning | 0.4-0.8μm | General industrial |

| Electropolished | Electrolytic polishing | 0.1-0.2μm | Ultra-clean systems |

| Oxide Scale | Controlled oxidation | 1.0-2.0μm | High temp applications |

Special consideration: Electropolishing removes the work-affected surface layer (5-10μm) that may contain residual stresses and microcracks from drawing operations.

Quality Testing Protocols

Standard quality verification tests:

| Test Type | Standard Reference | Acceptance Criteria | Frequency |

|---|---|---|---|

| Chemical Analysis | ASTM E1473 | Within alloy specs | Per heat/lot |

| Tensile Testing | ASTM E8 | UTS ≥690MPa (C276) | Per size/lot |

| Corrosion Test | ASTM G28 | ≤0.5mm/year | Quarterly |

| Microcleanliness | ASTM E45 | ≤1.5 non-metallics | Per heat |

Critical test: The ASTM G28 Method A test in ferric sulfate-sulfuric acid solution verifies the intergranular corrosion resistance which is essential for Hastelloy performance in chemical environments.

Production Challenges

Technical difficulties in Hastelloy wire manufacturing:

| Challenge | Impact | Mitigation Strategy |

|---|---|---|

| Work Hardening | Limited cold workability | Frequent intermediate annealing |

| Die Wear | Increased surface defects | Polycrystalline diamond dies |

| Residual Stresses | Dimensional instability | Stress relief annealing |

| Surface Oxidation | Drawing lubricant breakdown | Controlled atmosphere annealing |

Specialized requirement: Hastelloy’s high hot strength necessitates using premium tool steels or ceramic materials for hot working operations to withstand the extreme pressures required.

Related Questions

What makes Hastelloy wire manufacturing different from stainless steel wire production?

Hastelloy wire manufacturing requires significantly more controlled processes including vacuum melting, strict intermediate annealing protocols, specialized drawing lubricants, and more frequent quality testing due to the material’s work hardening characteristics and premium performance requirements.

How small can Hastelloy wire be drawn?

With proper process controls, Hastelloy alloys can be drawn down to 0.025mm (25 microns) diameter for specialized applications, though most commercial production stops at 0.1mm due to increasing breakage risks and exponentially higher costs.

Why does Hastelloy wire require hydrogen atmosphere annealing?

Hydrogen atmosphere annealing prevents surface oxidation while providing reducing conditions that help remove any existing oxide scale. This is particularly important for Hastelloy alloys to maintain their chromium content at the surface for optimal corrosion resistance.