Haynes 230 and Inconel 625 are two well-known nickel-based superalloys designed for demanding high-temperature and corrosive environments. While both alloys offer excellent oxidation and corrosion resistance, they are optimized for different service conditions. Haynes 230 is primarily engineered for extreme high-temperature strength and oxidation resistance, whereas Inconel 625 is widely valued for its combination of corrosion resistance, mechanical strength, and fabrication flexibility. Understanding the differences between Haynes 230 and Inconel 625 helps engineers and buyers select the most suitable material for aerospace, power generation, chemical processing, and industrial furnace applications.

Alloy Design Philosophy

Haynes 230 is a solid-solution strengthened nickel-chromium-tungsten-molybdenum alloy specifically developed for long-term exposure to very high temperatures. Its composition focuses on excellent thermal stability, oxidation resistance, and resistance to nitriding and carburization.

Inconel 625 is a nickel-chromium-molybdenum-niobium alloy designed to deliver high strength and outstanding corrosion resistance across a broad range of temperatures, including cryogenic and moderately high-temperature environments.

Chemical Composition Comparison

| Element | Haynes 230 | Inconel 625 |

|---|---|---|

| Nickel (Ni) | Balance | ≥ 58% |

| Chromium (Cr) | 20 – 24% | 20 – 23% |

| Molybdenum (Mo) | 1 – 3% | 8 – 10% |

| Tungsten (W) | 13 – 15% | — |

| Niobium (Nb) | — | 3.15 – 4.15% |

| Iron (Fe) | ≤ 3% | ≤ 5% |

| Carbon (C) | 0.05 – 0.15% | ≤ 0.10% |

The high tungsten content in Haynes 230 provides exceptional strength and microstructural stability at elevated temperatures, while the high molybdenum and niobium content in Inconel 625 enhances corrosion resistance and mechanical strength.

Mechanical Properties

Haynes 230 offers excellent creep resistance and stress rupture strength at temperatures exceeding 900°C, making it suitable for continuous high-temperature service.

Inconel 625 provides very high tensile and yield strength at room temperature and maintains good mechanical performance up to moderate high temperatures without requiring precipitation hardening.

| Property | Haynes 230 | Inconel 625 |

|---|---|---|

| Room Temperature Strength | Moderate | High |

| High-Temperature Strength | Excellent | Good |

| Creep Resistance | Outstanding | Moderate |

| Thermal Stability | Excellent | Good |

High-Temperature Performance

Haynes 230 is specifically designed for service temperatures up to approximately 1150°C. It maintains oxidation resistance and mechanical integrity during long-term exposure to heat, making it ideal for furnace components and gas turbine combustion hardware.

Inconel 625 typically performs well up to around 980°C, but its primary advantage lies in corrosion resistance rather than prolonged extreme-temperature exposure.

Corrosion and Oxidation Resistance

Haynes 230 exhibits excellent resistance to oxidation, nitriding, and carburization in high-temperature atmospheres. It is particularly effective in air and combustion gas environments.

Inconel 625 excels in resistance to pitting, crevice corrosion, chloride-induced stress corrosion cracking, and a wide range of acidic environments, including seawater and chemical processing fluids.

Fabrication and Weldability

Haynes 230 has good weldability and formability for a high-temperature alloy, but its high tungsten content can increase machining difficulty.

Inconel 625 is known for excellent weldability and fabrication versatility. It can be welded without post-weld heat treatment in many applications, although it tends to work-harden during machining.

Typical Applications

Haynes 230 Applications:

Industrial furnace components, heat shields, combustion liners, transition ducts, gas turbine hardware, thermal processing equipment, and high-temperature heat exchangers.

Inconel 625 Applications:

Offshore oil and gas piping, subsea systems, chemical processing equipment, heat exchangers, aerospace components, marine hardware, and nuclear industry applications.

Cost Comparison

Haynes 230 is generally priced higher for applications requiring long-term exposure to extreme temperatures due to its tungsten content and specialized performance characteristics.

Inconel 625 is more cost-effective for corrosion-resistant and high-strength applications that do not require continuous operation at ultra-high temperatures.

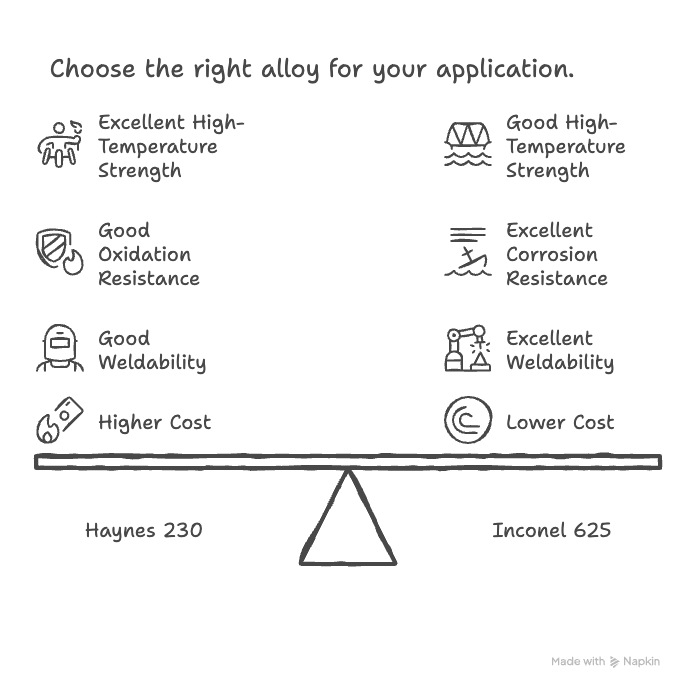

How to Choose Between Haynes 230 and Inconel 625

Choose Haynes 230 if: the application involves sustained exposure to very high temperatures, oxidation, or carburizing environments.

Choose Inconel 625 if: high corrosion resistance, mechanical strength, and fabrication flexibility are required across a wide range of temperatures.

Related Questions

Is Haynes 230 stronger than Inconel 625 at high temperatures?

Yes, Haynes 230 provides superior creep resistance and strength at very high temperatures compared with Inconel 625.

Which alloy is better for corrosion resistance?

Inconel 625 generally offers better resistance to aqueous corrosion and chloride environments.

Can Haynes 230 replace Inconel 625?

No, Haynes 230 is optimized for high-temperature environments, while Inconel 625 is better suited for corrosion-resistant structural applications.