Haynes 25, also known as L605 or UNS R30605, is a cobalt-based high-temperature alloy widely used in aerospace, gas turbines, industrial furnaces, and wear-resistant components. Due to its excellent strength at elevated temperatures, oxidation resistance, and sulfidation resistance, Haynes 25 is typically produced only by specialized superalloy factories with advanced melting, forging, and heat-treatment capabilities. Understanding what a Haynes 25 factory can produce and how the material is manufactured helps buyers source reliable and certified alloy products.

What Is Haynes 25 Alloy?

Haynes 25 is a cobalt-chromium-tungsten-nickel alloy designed for high-temperature and high-stress environments. It maintains mechanical strength and surface stability at elevated temperatures while offering good resistance to oxidation, thermal fatigue, and wear.

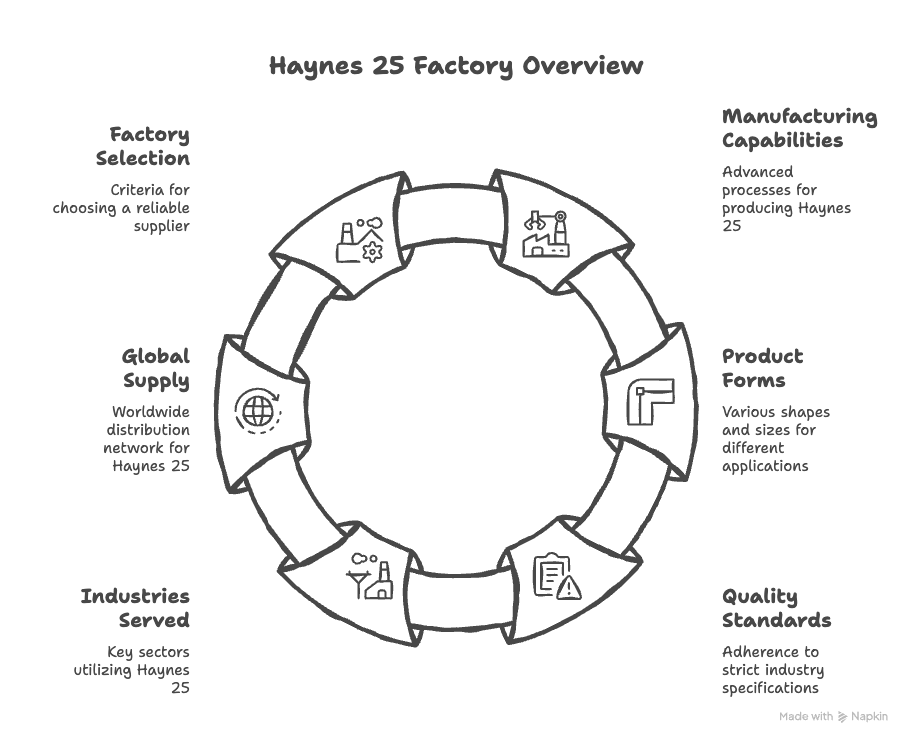

Who Produces Haynes 25?

Haynes 25 is originally developed and commercially produced by established superalloy manufacturers. These producers operate dedicated alloy facilities capable of melting cobalt-based alloys and processing them into certified industrial forms. In addition to original alloy developers, qualified regional alloy factories and metal processors may supply Haynes 25 in finished or semi-finished forms based on mill-produced material.

Haynes 25 Factory Manufacturing Capabilities

A qualified Haynes 25 factory typically offers the following capabilities:

Vacuum or controlled atmosphere melting to ensure precise chemical composition and alloy cleanliness.

Hot forging and rolling to produce bars, plates, and billets with uniform mechanical properties.

Solution heat treatment to optimize strength, ductility, and high-temperature performance.

Precision machining and finishing for tight dimensional tolerance requirements.

Inspection and testing including chemical analysis, mechanical testing, and non-destructive examination.

Available Product Forms from Haynes 25 Factories

Haynes 25 is commonly supplied in multiple product forms to meet different industrial needs:

| Product Form | Typical Use |

|---|---|

| Round bar / rod | Machined aerospace and turbine components |

| Sheet / plate | Heat shields, furnace parts, formed components |

| Wire | Springs, welding consumables, precision parts |

| Forgings / billets | High-strength structural components |

Quality Standards and Specifications

Haynes 25 products are usually manufactured to strict industry standards depending on the product form. Common specifications include aerospace material standards for bar, sheet, and welding wire. Certified factories provide full material traceability, mill test certificates, and compliance documentation.

Typical Industries Served by Haynes 25 Factories

Aerospace and Gas Turbines: turbine blades, combustion components, fasteners.

Industrial Furnaces: heat-resistant fixtures, trays, and support structures.

Power Generation: high-temperature wear components.

Medical and Precision Engineering: specialized wear-resistant or high-strength parts.

Global Supply and Factory Distribution

Haynes 25 is produced primarily in regions with advanced alloy manufacturing infrastructure. Some factories focus on primary melting and rolling, while others specialize in secondary processing such as cutting, machining, or custom fabrication. Buyers may source Haynes 25 directly from mills, through authorized distributors, or from export-oriented alloy factories offering customized dimensions.

How to Choose a Reliable Haynes 25 Factory

Manufacturing capability: Ensure the factory can handle cobalt-based alloy melting or certified downstream processing.

Certification: Verify compliance with ASTM, AMS, or customer-specific standards.

Experience: Look for proven experience supplying aerospace or high-temperature industries.

Customization: Confirm the ability to produce non-standard sizes or special heat treatment conditions.

Related Questions

Is Haynes 25 produced by many factories?

No, Haynes 25 is typically produced by specialized superalloy manufacturers and qualified processing factories due to its cobalt-based composition.

What forms can a Haynes 25 factory supply?

Bars, plates, sheets, wire, forgings, and custom-machined components are commonly available.

Can Haynes 25 be custom-made by factories?

Yes, many factories offer customized sizes, heat treatment, and finishing based on customer requirements.