Haynes 282 and Inconel 718 are both high-performance nickel-based alloys widely used in aerospace, power generation, and high-temperature applications. While they share similarities such as excellent corrosion resistance and strength at elevated temperatures, they differ significantly in terms of mechanical properties, thermal stability, and fabrication characteristics. This article provides a detailed comparison between Haynes 282 and Inconel 718 to help engineers and designers make informed material selection decisions.

Chemical Composition

Haynes 282 primarily consists of nickel (~55%), chromium (~19%), cobalt (~8%), molybdenum (~2.5%), with small additions of aluminum, titanium, and iron. In contrast, Inconel 718 is composed of nickel (50–55%), chromium (17–21%), iron (balance), niobium (4.75–5.5%), molybdenum (2.8–3.3%), and minor amounts of titanium and aluminum. The higher cobalt content in Haynes 282 enhances high-temperature strength and oxidation resistance, whereas the niobium in Inconel 718 provides precipitation strengthening.

Mechanical Properties

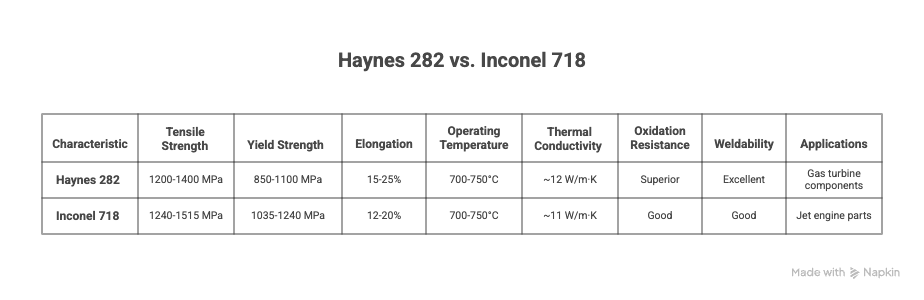

Both alloys exhibit excellent mechanical strength, but differences exist:

- Tensile Strength: Inconel 718 typically ranges from 1,240–1,515 MPa, while Haynes 282 achieves around 1,200–1,400 MPa at room temperature, with superior retention of strength at temperatures above 650°C.

- Yield Strength: Inconel 718: 1,035–1,240 MPa; Haynes 282: 850–1,100 MPa.

- Elongation: Haynes 282 exhibits slightly higher ductility (15–25%) compared to Inconel 718 (12–20%), making it easier to form complex geometries.

- Hardness: Both alloys have comparable hardness ranges, with Inconel 718 slightly harder in aged conditions.

Thermal Properties

Haynes 282 is designed for high-temperature creep resistance and stability:

- Operating Temperature: Haynes 282 can operate effectively up to 700–750°C, similar to Inconel 718.

- Melting Point: Haynes 282: ~1,345–1,370°C; Inconel 718: ~1,360–1,370°C.

- Thermal Expansion: Haynes 282: 13.0 × 10⁻⁶ /°C; Inconel 718: 13.0 × 10⁻⁶ /°C, showing similar expansion behavior under thermal cycling.

- Thermal Conductivity: Slightly higher in Haynes 282 (~12 W/m·K) compared to Inconel 718 (~11 W/m·K), which can reduce thermal gradients in some components.

Corrosion and Oxidation Resistance

Both alloys resist oxidation and corrosion at high temperatures. Inconel 718 is particularly resistant to chloride-induced stress corrosion cracking, while Haynes 282 demonstrates superior oxidation resistance in air and combustion environments due to its cobalt and aluminum content, which forms a stable protective oxide layer.

Fabrication and Weldability

Haynes 282 is known for its excellent weldability and lower tendency to cracking during fabrication. It can be readily formed into complex geometries without extensive post-weld heat treatment. Inconel 718, although weldable, requires careful control of heat input and post-weld aging to avoid hot cracking and retain strength, making fabrication more challenging.

Applications

Both alloys find use in extreme environments, but with slightly different focuses:

- Haynes 282: Gas turbine engine components, combustor liners, structural aerospace parts requiring long-term high-temperature creep resistance.

- Inconel 718: Jet engine parts, rocket motor cases, turbine blades, and chemical processing equipment where high strength and corrosion resistance are critical.

Related Questions

Which is stronger, Haynes 282 or Inconel 718? Inconel 718 generally has higher tensile and yield strength at room temperature, but Haynes 282 maintains strength better at very high temperatures.

Which alloy is easier to weld? Haynes 282 is easier to weld with lower risk of cracking, whereas Inconel 718 requires careful heat treatment after welding.

Can Haynes 282 replace Inconel 718? It depends on the application: Haynes 282 is preferable for high-temperature creep and oxidation resistance, while Inconel 718 is ideal for applications demanding maximum strength and corrosion resistance at elevated temperatures.