Heat resistant nickel alloy plates are engineered to perform under extreme temperatures and corrosive environments. These alloys—such as Inconel 600, Inconel 625, Inconel 718, Hastelloy X, and Nickel 201—are widely used in aerospace, petrochemical, furnace, power generation, and nuclear sectors. In 2025, the price of heat resistant nickel alloy plates varies based on alloy composition, thickness, region, certification, and global raw material costs. This article breaks down the latest pricing for these specialized plates by grade, thickness, and origin.

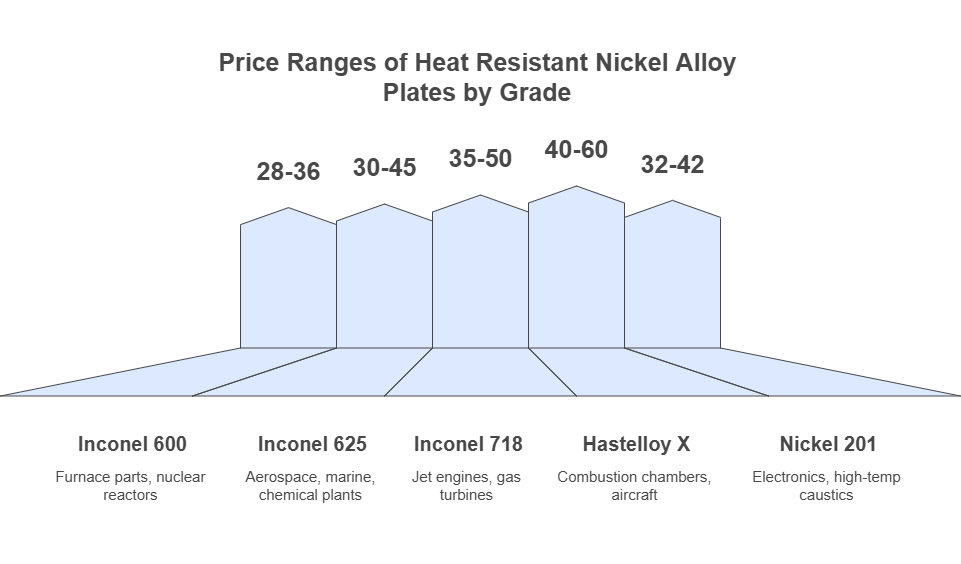

Price of Heat Resistant Nickel Alloy Plates by Grade (USD/kg)

| Alloy | Heat Resistance | Price Range (USD/kg) | Common Applications |

|---|---|---|---|

| Inconel 600 | Up to 1150°C | 28 – 36 | Furnace parts, nuclear reactors |

| Inconel 625 | Up to 1000°C | 30 – 45 | Aerospace, marine, chemical plants |

| Inconel 718 | Up to 700°C (high strength) | 35 – 50 | Jet engines, gas turbines |

| Hastelloy X | Up to 1175°C | 40 – 60 | Combustion chambers, aircraft |

| Nickel 201 | Good thermal resistance | 32 – 42 | Electronics, high-temp caustics |

Heat Resistant Nickel Plate Price by Thickness

| Thickness (mm) | Standard Size (mm) | Price Range (USD/kg) | Notes |

|---|---|---|---|

| 0.5 – 1.5 | 1000 x 2000 | 35 – 55 | Thin plate for insulation and liners |

| 1.5 – 3.0 | 1200 x 2400 | 33 – 48 | General high-temp equipment |

| 3.0 – 6.0 | 1500 x 3000 | 30 – 45 | Structural components, baffles |

| 6.0 – 10.0 | Custom | 28 – 43 | Furnace bases, heat shields |

Global Price Comparison for Heat Resistant Nickel Plates (2025, USD/kg)

| Country | Common Alloys | Average Price Range | Comments |

|---|---|---|---|

| China | 600, 625, 718 | 28 – 42 | Most affordable for standard orders |

| India | 600, 625, X | 30 – 45 | Rising quality with good pricing |

| USA | 625, 718, X | 38 – 55 | Preferred for certified, aerospace-grade material |

| Germany | 718, X | 42 – 60 | High-performance, low-tolerance supply |

Influencing Factors for Heat Resistant Nickel Plate Pricing

1. Alloying Elements: High contents of Ni, Cr, Mo, Nb, Co, and Fe contribute significantly to material cost.

2. Surface Condition: Bright annealed, ground, or polished plates may cost 5–20% more than mill finish.

3. Certifications: Pricing increases when plates are certified to ASTM B443, AMS 5599, or NACE MR0175 standards.

4. Order Size: Large bulk orders (over 1 ton) typically receive factory-level discounts of 5–10% per kg.

5. Cutting and Packaging: Special sizes, laser cutting, or export packaging (wood crates, fumigation) add cost per unit.

Examples of Estimated Plate Cost by Alloy and Size

| Alloy | Size (mm) | Thickness (mm) | Weight (kg) | Approx. Cost (USD) |

|---|---|---|---|---|

| Inconel 600 | 1000 x 2000 | 2.0 | ≈ 32 kg | 900 – 1150 |

| Inconel 625 | 1200 x 2400 | 3.0 | ≈ 86 kg | 2800 – 3700 |

| Hastelloy X | 1500 x 3000 | 5.0 | ≈ 180 kg | 7200 – 10800 |

Related Questions and Answers

What is the most affordable heat resistant nickel alloy plate in 2025?

Inconel 600 offers reliable heat resistance at the lowest cost, with factory prices starting around USD 28–30/kg.

Which alloy is best for extreme high-temperature resistance?

Hastelloy X and Inconel 600 are among the best for temperatures exceeding 1100°C in industrial applications.

Where can I find certified heat resistant nickel alloy plates?

Certified suppliers are located in the USA, Germany, China, and India. Look for ASTM B443, AMS, or NORSOK certifications depending on your sector.