Inconel is a family of nickel-chromium-based superalloys widely used in aerospace, marine, nuclear, and chemical industries due to its excellent resistance to extreme temperatures, oxidation, and corrosion. In 2025, the price of Inconel varies by grade, form, region, and market demand. This article explores the typical per-pound cost of Inconel alloys in 2025, with detailed breakdowns by grade, product form, and influencing factors.

Average Inconel Price Per Pound in 2025

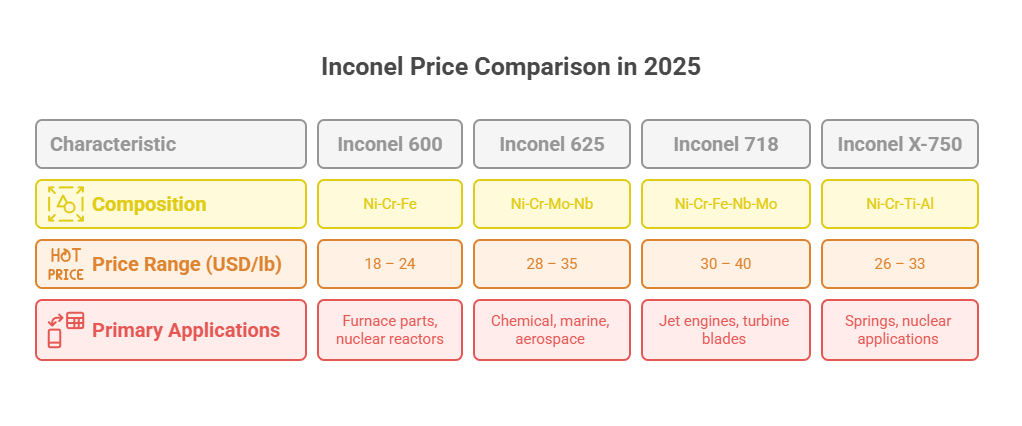

| Inconel Grade | Typical Composition | Price Range (USD/lb) | Primary Applications |

|---|---|---|---|

| Inconel 600 | Ni-Cr-Fe | 18 – 24 | Furnace parts, nuclear reactors |

| Inconel 625 | Ni-Cr-Mo-Nb | 28 – 35 | Chemical, marine, aerospace |

| Inconel 718 | Ni-Cr-Fe-Nb-Mo | 30 – 40 | Jet engines, turbine blades |

| Inconel X-750 | Ni-Cr-Ti-Al | 26 – 33 | Springs, nuclear applications |

Inconel Price by Product Form

| Product Form | Price Range (USD/lb) | Notes |

|---|---|---|

| Round Bar | 28 – 40 | Common for aerospace & oil tools |

| Plate/Sheet | 25 – 38 | Flat products with tight tolerances |

| Wire | 30 – 45 | Higher cost due to processing |

| Powder | 60 – 100 | Used in additive manufacturing |

Factors Affecting Inconel Prices in 2025

1. Alloying Elements: Inconel contains expensive elements like nickel (≥50%), molybdenum, niobium, and chromium, all of which contribute significantly to its price.

2. Grade-Specific Strength: Precipitation-hardened grades like Inconel 718 cost more due to complex heat treatments and aerospace certification needs.

3. Market Demand: Increased use in aerospace, nuclear, and green energy sectors is driving up prices in 2025.

4. Supplier Region: Inconel sourced from USA or Europe is priced higher than from China or India due to labor and compliance costs.

5. Order Volume: Large-volume orders benefit from lower unit pricing, while small batches include cutting, certification, and minimum charges.

Regional Price Comparison for Inconel 625 (USD/lb)

| Region | Average Price | Notes |

|---|---|---|

| USA | 30 – 35 | Certified aerospace and nuclear-grade supply |

| Europe | 32 – 38 | Strict quality control and traceability |

| China | 25 – 31 | Competitive for industrial-grade material |

| India | 26 – 33 | Strong in pipe, bar, and sheet exports |

Scrap and Recycled Inconel Pricing

Recycled Inconel scrap prices are much lower than virgin alloy, averaging USD 5 – 8/lb depending on grade, cleanliness, and alloy type. However, scrap is mostly reused in foundries and is not suitable for precision aerospace or nuclear applications.

Tips for Getting Best Price

• Request mill test certificates (MTC) with chemical analysis to verify alloy.

• Consider sourcing from secondary processors for non-critical applications.

• Buy standard lengths and forms to avoid custom surcharges.

• Compare FOB vs. CIF pricing to evaluate full landed cost.

Related Questions and Answers

What is the current price of Inconel 625 per pound in 2025?

In 2025, Inconel 625 averages between USD 28 to 35 per pound depending on supplier, region, and form (bar, sheet, wire).

Why is Inconel more expensive than stainless steel?

Inconel contains a high percentage of nickel, molybdenum, and other costly elements, and it undergoes more complex heat treatments and certifications than standard stainless steels.

Where can I buy Inconel at the best price?

Industrial buyers can find competitive pricing from certified suppliers in China or India, especially for large-volume orders or non-aerospace use. U.S. and European suppliers are preferred for certified, high-spec applications.