Incoloy 800 plate is a high-performance nickel-iron-chromium alloy product known for its excellent resistance to high-temperature oxidation and carburization. It is widely used in heat exchangers, furnace components, chemical processing, and power generation. Incoloy 800 plates are manufactured in thicknesses ranging from 3mm to over 100mm and are typically produced to meet standards such as ASTM B409 and ASME SB409. China, India, the U.S., and Europe all host factories capable of producing Incoloy 800 plates for global industrial applications. This guide focuses on the key manufacturers, plate specifications, and common industrial uses.

Specifications of Incoloy 800 Plates

Factories manufacture Incoloy 800 plates in a range of dimensions and surface finishes, suitable for both structural and pressure-containing applications.

| Thickness | Width | Length | Standards |

|---|---|---|---|

| 3mm – 100mm+ | 1000mm – 2500mm | 2000mm – 6000mm (or custom) | ASTM B409 / ASME SB409 |

Top Incoloy 800 Plate Factories

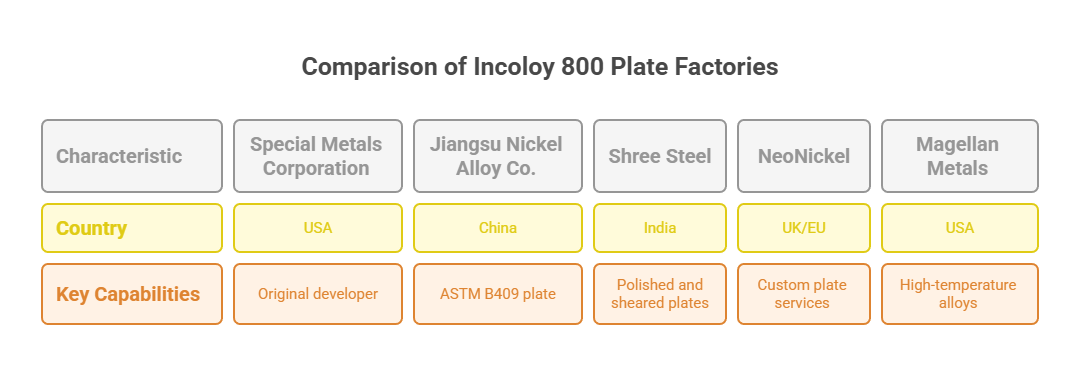

The following manufacturers are globally recognized for their production of high-quality Incoloy 800 plates:

| Factory Name | Country | Key Capabilities |

|---|---|---|

| Special Metals Corporation | USA | Original developer of Incoloy 800 alloy plates |

| Jiangsu Nickel Alloy Co., Ltd. | China | ASTM B409 Incoloy plate, cut-to-size |

| Shree Steel India | India | Polished and sheared Incoloy 800/800H/800HT plates |

| NeoNickel | UK/EU | Custom plate cutting, machining, and stocking |

| Magellan Metals | USA | High-temperature nickel alloy plates and sheets |

Surface Finishes and Processing Services

Factories offer Incoloy 800 plates in various finishes depending on application requirements:

| Finish | Description | Application |

|---|---|---|

| Hot Rolled (HR) | Mill scale surface, suitable for structural use | Furnaces, reactor linings |

| Cold Rolled (CR) | Smooth, refined surface with tighter tolerances | Heat exchanger shells |

| Pickled & Annealed | Scale removed, soft and clean surface | Fabrication and welding |

| Polished (No. 4, No. 8) | Mirror or brushed finish | Sanitary and architectural use |

Industries Using Incoloy 800 Plates

Due to their mechanical stability and resistance to high-temperature corrosion, Incoloy 800 plates are utilized across many sectors:

| Industry | Application |

|---|---|

| Heat Treatment | Furnace liners, trays, baskets |

| Chemical Processing | Acid tanks, pressure vessels |

| Oil & Gas | Reformer tubes, transfer lines |

| Power Generation | Steam generator shrouds and covers |

Certifications and Quality Control

Incoloy 800 plate factories offer quality certification and traceability for each batch produced:

| Certification | Purpose |

|---|---|

| ASTM B409 / ASME SB409 | Compliance with material standards |

| EN 10204 3.1 / 3.2 | Mill Test Certificates with test results |

| ISO 9001 | Quality management system certification |

| CE / PED | EU conformity for pressure equipment |

FAQs About Incoloy 800 Plate Factories

Which countries have major Incoloy 800 plate factories?

China, India, the USA, and EU nations are home to major factories supplying Incoloy 800 plates globally.

What is the standard specification for Incoloy 800 plates?

Incoloy 800 plates are typically manufactured to ASTM B409 or ASME SB409 standards for flat-rolled products.

What surface finishes are available for Incoloy 800 plates?

Common finishes include hot rolled, cold rolled, pickled & annealed, and polished (No. 4 or No. 8) depending on the application.