Incoloy 800 wire is a high-temperature nickel-iron-chromium alloy wire known for its excellent resistance to oxidation, carburization, and general corrosion at elevated temperatures. It is commonly used in electric heating elements, thermocouple sheaths, furnace wiring, and thermal processing equipment. Incoloy 800 wires are manufactured to precise diameters and mechanical properties, typically in accordance with ASTM B408 or customer-specific standards. Leading manufacturers in China, India, the USA, and Europe supply Incoloy 800 wire in annealed, hard-drawn, or bright conditions for industrial and high-temperature applications.

Specifications of Incoloy 800 Wire

Incoloy 800 wire is available in a variety of sizes, spool types, and tempers depending on the intended application.

| Diameter Range | Standard | Temper | Packaging |

|---|---|---|---|

| 0.05mm – 6.0mm | ASTM B408, UNS N08800 | Annealed, Hard-Drawn | Coils, Spools, Straight Lengths |

Top Incoloy 800 Wire Manufacturers

These manufacturers produce and export Incoloy 800 wire globally, supplying various industrial sectors:

| Manufacturer | Location | Key Products |

|---|---|---|

| Jiangsu Nickel Alloy Co., Ltd. | China | Bright and annealed Incoloy wire, spools |

| Shanghai Tankii Alloy Material Co., Ltd. | China | High-precision resistance and heating wires |

| Ulbrich Stainless Steels & Special Metals | USA | Custom-drawn nickel alloy fine wire |

| VDM Metals GmbH | Germany | High-temperature wire for aerospace and energy |

| Bhansali Nickel Alloys | India | Weld wire, heating elements, thermocouple wires |

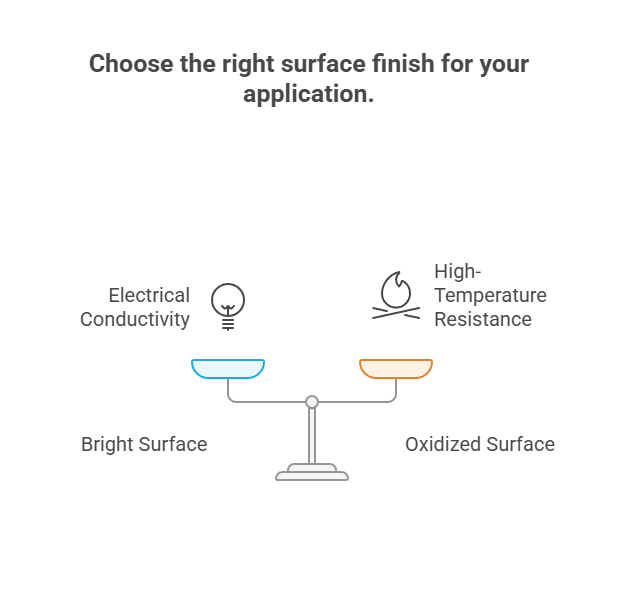

Surface Finishes and Coil Forms

Incoloy 800 wire is supplied in different surface conditions and winding formats:

| Finish | Description |

|---|---|

| Bright | Surface-cleaned, suitable for electrical applications |

| Oxidized | Used for high-temperature, open-air applications |

| Matte | Slightly roughened, general industrial use |

| Form | Use |

|---|---|

| Loose Coil | For furnace rebuilding and general industrial wiring |

| Plastic Spool | For resistance welding, precision coiling |

| Straight Lengths | Used in thermocouples and fixed assemblies |

Common Applications of Incoloy 800 Wire

Due to its corrosion and thermal resistance, Incoloy 800 wire is used in a variety of high-stress environments:

| Industry | Application |

|---|---|

| Thermal Processing | Furnace elements, tray wiring |

| Electric Heating | Strip heaters, tubular heating wires |

| Instrumentation | Thermocouple wire sheathing |

| Chemical Industry | Resistance wires for corrosive gas environments |

Certifications and Quality Control

Reputable manufacturers ensure each spool of Incoloy 800 wire complies with international specifications:

| Certification | Purpose |

|---|---|

| ASTM B408 | Standard for Incoloy 800 rod and wire |

| EN 10204 3.1 | Mill Test Certificate with test results |

| ISO 9001 | Quality assurance certification |

| RoHS / CE | Environmental and European compliance |

FAQs About Incoloy 800 Wire Manufacturers

What is the smallest diameter Incoloy 800 wire available?

Manufacturers can supply fine wire down to 0.05mm, especially for heater elements and thermocouples.

Can Incoloy 800 wire be used for electric heating?

Yes, it is commonly used in strip heaters and tubular heaters due to its high-temperature strength and corrosion resistance.

Where are Incoloy 800 wire manufacturers located?

Top producers are located in China, India, Germany, and the United States, all capable of exporting globally.