Incoloy 825 bar is a high-performance nickel-iron-chromium alloy product with additional elements like molybdenum, copper, and titanium, designed for superior resistance to acid attack, especially sulfuric and phosphoric acids. Incoloy 825 bars are widely used in chemical processing, pollution control, marine, and oil & gas industries. These bars are produced in round, square, hex, and flat shapes, usually conforming to ASTM B425 or ASME SB425 standards. This article explores the capabilities of top Incoloy 825 bar factories, material specifications, and product applications.

Specifications of Incoloy 825 Bars

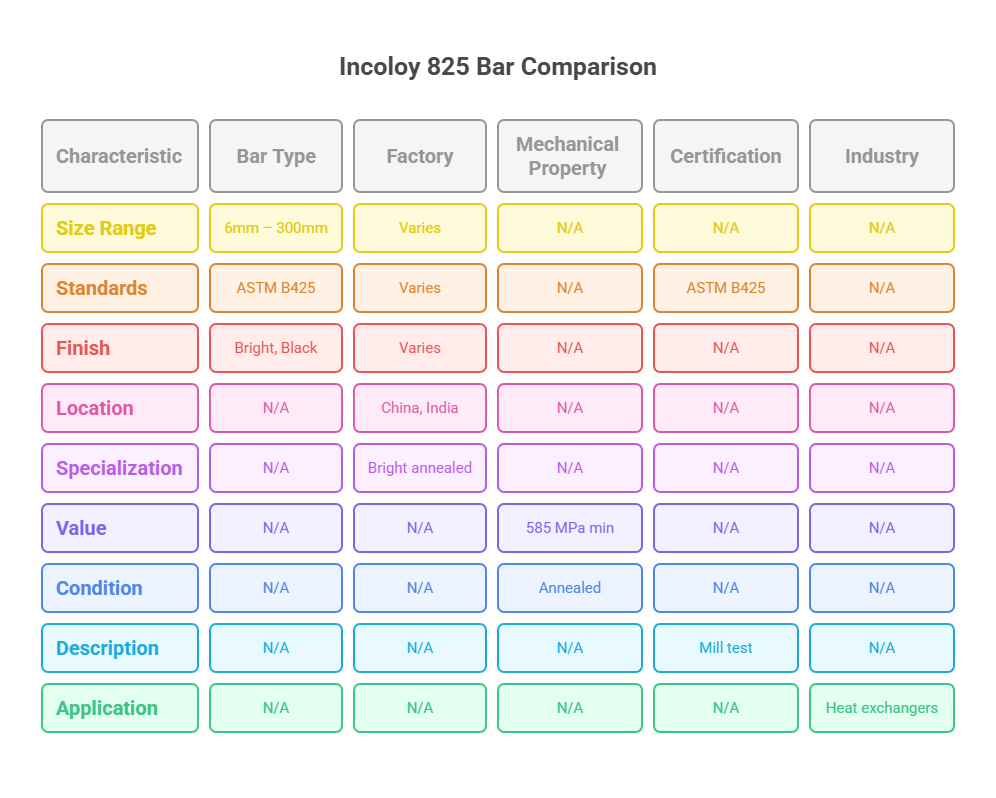

Bar factories offer a wide range of sizes, shapes, and mechanical conditions to meet industrial needs.

| Bar Type | Size Range | Standards | Finish |

|---|---|---|---|

| Round Bar | 6mm – 300mm | ASTM B425 / ASME SB425 | Bright, Black, Peeled, Ground |

| Square Bar | 10mm – 100mm | ASTM B425 | Hot Rolled / Cold Drawn |

| Hex Bar | Across flats 10mm – 75mm | ASTM B425 | Polished / Annealed |

| Flat Bar | Width 10mm – 200mm | ASTM B425 | Hot Rolled / Pickled |

Top Incoloy 825 Bar Factories

These factories are known for their advanced production capabilities, global export support, and strict quality control.

| Factory Name | Location | Specialization |

|---|---|---|

| Jiangsu Nickel Alloy Co., Ltd. | China | Bright annealed & turned Incoloy bars |

| Wenzhou Chiron Alloy Materials Co., Ltd. | China | Round, hex, and flat bar production |

| NeoNickel | UK / EU | Precision machined alloy bars |

| Piyush Steel | India | ASTM B425 Incoloy bars & export packaging |

| Special Metals | USA | Original alloy developer and mill production |

Mechanical Properties of Incoloy 825 Bars

Typical mechanical properties of Incoloy 825 bar in the annealed condition:

| Property | Value | Condition |

|---|---|---|

| Tensile Strength | 585 MPa min | Annealed |

| Yield Strength (0.2%) | 220 MPa min | Annealed |

| Elongation | 30% min | Annealed |

| Hardness | ≤ 80 HRB | Annealed |

Certifications and Quality Assurance

Incoloy 825 bar factories provide international certifications to ensure material traceability and compliance:

| Certification | Description |

|---|---|

| ASTM B425 | Standard specification for rod, bar, and wire |

| EN 10204 3.1 / 3.2 | Mill test certificates with mechanical/chemical analysis |

| ISO 9001 | Certified quality management system |

| CE / PED | European Pressure Equipment Directive compliance |

Industries Using Incoloy 825 Bars

The corrosion resistance and strength of Incoloy 825 bars make them ideal for use in various sectors:

| Industry | Application |

|---|---|

| Chemical Processing | Heat exchangers, tanks, pipelines |

| Marine Engineering | Seawater piping and shafts |

| Pollution Control | Flue gas scrubbers, exhaust systems |

| Oil & Gas | Downhole tools, control lines |

FAQs About Incoloy 825 Bar Factories

What shapes of Incoloy 825 bars are available from factories?

Factories supply round, hexagonal, square, and flat bars depending on the end-use requirement.

What certifications are typically provided with Incoloy 825 bars?

Bars usually come with ASTM B425 compliance and EN 10204 3.1 or 3.2 Mill Test Certificates, along with ISO 9001 and CE/PED certification if required.

Where are the major Incoloy 825 bar factories located?

Major factories are located in China, India, the USA, and Europe, with extensive global export experience and support for custom machining and surface finishing.