Incoloy 825 bolts are high-performance fasteners made from a nickel-iron-chromium alloy with added molybdenum, copper, and titanium. These bolts offer excellent resistance to oxidizing and reducing acids, stress corrosion cracking, and pitting in chloride-rich environments. They are widely used in chemical processing, offshore platforms, pollution control equipment, and nuclear fuel reprocessing. Suppliers offer Incoloy 825 bolts in various types, sizes, and standards, often manufactured to ASTM B425 and ASME specifications. This article outlines key suppliers, available bolt types, and relevant certifications.

Specifications of Incoloy 825 Bolts

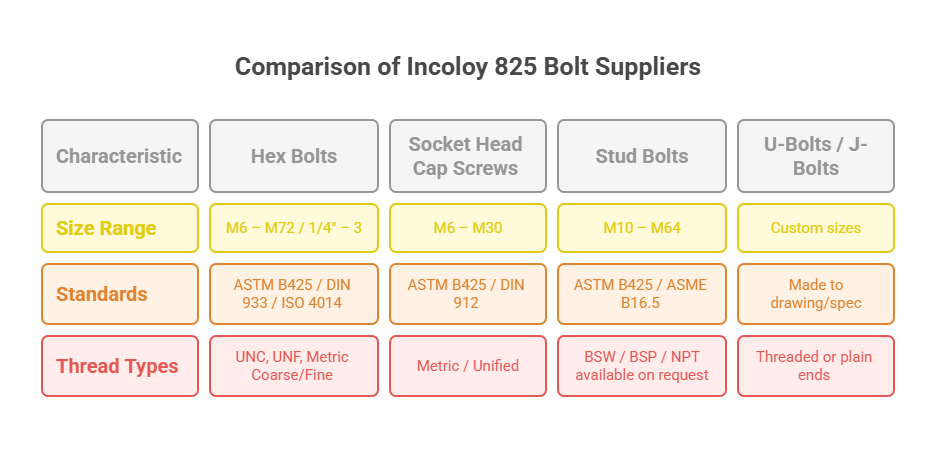

Incoloy 825 bolts are available in several configurations to suit industrial applications requiring high corrosion resistance.

| Type | Size Range | Standards | Thread Types |

|---|---|---|---|

| Hex Bolts | M6 – M72 / 1/4″ – 3″ | ASTM B425 / DIN 933 / ISO 4014 | UNC, UNF, Metric Coarse/Fine |

| Socket Head Cap Screws | M6 – M30 | ASTM B425 / DIN 912 | Metric / Unified |

| Stud Bolts | M10 – M64 | ASTM B425 / ASME B16.5 | BSW / BSP / NPT available on request |

| U-Bolts / J-Bolts | Custom sizes | Made to drawing/spec | Threaded or plain ends |

Top Global Suppliers of Incoloy 825 Bolts

These suppliers specialize in Incoloy 825 fasteners, offering custom and standard configurations for global industries.

| Supplier Name | Location | Specialization |

|---|---|---|

| Kalp Industries | India | Full range of Incoloy fasteners including 825 bolts |

| Jiangsu Nickel Alloy Co., Ltd. | China | Custom machined alloy bolts and nuts |

| NeoNickel | UK / EU | High-spec alloy bolts for aerospace and chemical sectors |

| Raaj Sagar Steels | India | Metric and inch bolts in Incoloy 825, with coatings |

| Magellan Metals | USA | Incoloy 825 bolts with material traceability |

Surface Finish and Coating Options

Suppliers offer various surface treatments and coatings to enhance corrosion resistance or meet application needs:

| Finish | Description |

|---|---|

| Plain (Uncoated) | Natural finish, typically used in high-temperature systems |

| Passivated | Enhanced corrosion resistance via acid treatment |

| PTFE Coated | Low-friction and anti-galling properties |

| Electro-Polished | Mirror finish for cleanroom and sanitary use |

Industries Using Incoloy 825 Bolts

Incoloy 825 bolts are used where high strength and resistance to acids, seawater, and aggressive chemicals are essential:

| Industry | Application |

|---|---|

| Chemical Processing | Reactors, tanks, and acid-handling systems |

| Marine & Offshore | Flange bolting, submerged fittings |

| Oil & Gas | Downhole equipment, pipelines, wellheads |

| Power Generation | Heat exchangers, scrubbers, condensers |

Certifications and Quality Control

Suppliers provide certified documentation with each batch to ensure compliance with international standards:

| Certification | Description |

|---|---|

| ASTM B425 | Specification for Incoloy 825 bar used in bolt production |

| EN 10204 3.1 / 3.2 | Mill test certificates with chemical & mechanical properties |

| ISO 9001 | Quality management systems certification |

| CE / PED | Compliance for pressure-bearing components in the EU |

FAQs About Incoloy 825 Bolt Suppliers

What types of Incoloy 825 bolts are most commonly supplied?

Hex bolts, socket cap screws, stud bolts, and U-bolts are among the most commonly requested types, available in both metric and imperial sizes.

Do suppliers offer custom sizes or threading options?

Yes, most suppliers can machine Incoloy 825 bolts to custom lengths, diameters, and thread types, including metric fine, UNC, or BSP as needed.

Which countries have leading Incoloy 825 bolt suppliers?

India, China, the USA, and select European countries such as Germany and the UK are home to reliable manufacturers and exporters of Incoloy 825 bolts.