Incoloy 825 pipe is a corrosion-resistant alloy pipe made from a nickel-iron-chromium base with additions of molybdenum, copper, and titanium. It is especially effective in handling sulfuric acid, phosphoric acid, and seawater corrosion, making it ideal for chemical processing, marine, pollution control, and nuclear fuel applications. Chinese factories are among the largest global producers of Incoloy 825 pipes, offering seamless and welded options in compliance with ASTM B423 and other international standards. This article highlights leading factories, manufacturing capabilities, and technical specifications.

Common Specifications of Incoloy 825 Pipes

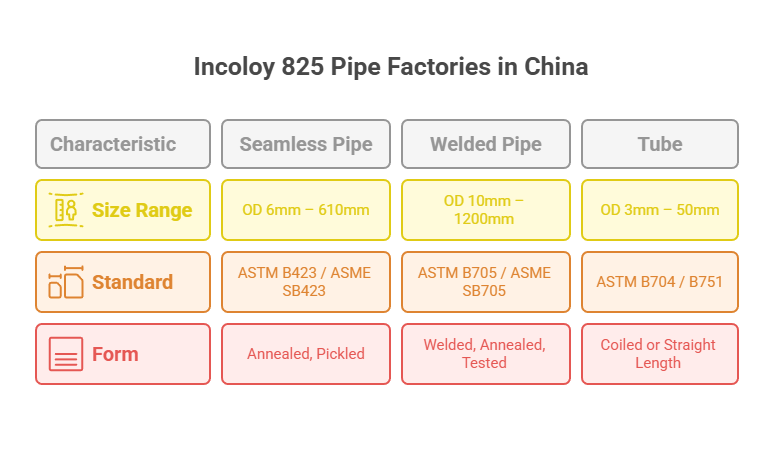

Chinese pipe factories produce Incoloy 825 pipes in a variety of dimensions and manufacturing processes:

| Type | Size Range | Standard | Form |

|---|---|---|---|

| Seamless Pipe | OD 6mm – 610mm | ASTM B423 / ASME SB423 | Annealed, Pickled |

| Welded Pipe | OD 10mm – 1200mm | ASTM B705 / ASME SB705 | Welded, Annealed, Tested |

| Tube | OD 3mm – 50mm | ASTM B704 / B751 | Coiled or Straight Length |

Top Incoloy 825 Pipe Factories in China

These Chinese manufacturers are known for producing and exporting Incoloy 825 pipes globally:

| Factory Name | Location | Key Capabilities |

|---|---|---|

| Jiangsu Huacheng Industry Pipe Making Co., Ltd. | Jiangyin, China | Seamless and welded Incoloy pipes, large OD range |

| Wuxi Xinfeng Pipe Industry Co., Ltd. | Wuxi, China | Precision tube rolling, custom lengths, NDT testing |

| Zhejiang Zhongda Special Steel Co., Ltd. | Zhejiang, China | ASTM B423/705 compliant alloy piping systems |

| Shanghai Fortune Group | Shanghai, China | Export-grade Incoloy pipes, MTC with each batch |

| Jiangsu Nickel Alloy Co., Ltd. | Suzhou, China | Nickel alloy seamless pipe production with bright annealing |

Certifications and Quality Control

Chinese Incoloy 825 pipe factories maintain high-quality standards and testing procedures:

| Certification | Description |

|---|---|

| ASTM B423 / B705 | Material specification for Incoloy 825 pipe |

| EN 10204 3.1 / 3.2 | Mill Test Certificates with full traceability |

| ISO 9001 | Quality management certification |

| Ultrasonic Testing (UT) | Internal defect detection |

| Hydrostatic / PMI Testing | Pressure integrity and material verification |

Applications of Incoloy 825 Pipes

Due to its resistance to acids and seawater, Incoloy 825 pipe is widely used in critical process environments:

| Industry | Application |

|---|---|

| Chemical Processing | Acid transport piping, heat exchangers |

| Oil & Gas | Sour gas pipelines, downhole tubing |

| Marine Engineering | Seawater piping, desalination units |

| Pollution Control | Flue gas scrubber pipelines |

FAQs About Incoloy 825 Pipe Factories in China

Do Chinese factories provide custom lengths and wall thicknesses?

Yes, most factories offer custom OD, wall thickness, and cut-to-length services based on client drawings or project requirements.

Are Chinese Incoloy 825 pipes tested before delivery?

Reputable Chinese factories conduct hydrostatic, ultrasonic, and PMI tests to verify pressure resistance and material composition.

Can Chinese factories export Incoloy 825 pipe globally?

Yes, leading factories in China have export licenses and provide complete shipping, packaging, and documentation support for global orders.