Incoloy 825 threaded fittings are corrosion-resistant alloy components designed for use in high-stress and chemically aggressive environments. Manufactured from a nickel-iron-chromium alloy with molybdenum, copper, and titanium, these fittings offer excellent resistance to acid attack, pitting, and chloride-induced corrosion. Threaded fittings are commonly used in low-pressure pipelines, chemical injection systems, offshore platforms, and marine installations. This article introduces the types of Incoloy 825 threaded fittings, key manufacturers, and their certifications.

Types of Incoloy 825 Threaded Fittings

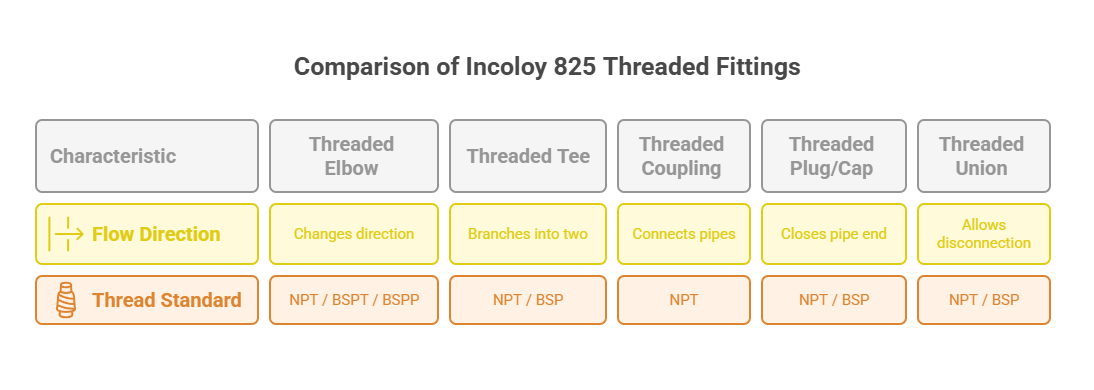

Threaded fittings come in various shapes and sizes to support pipe connections, direction changes, and terminations.

| Fitting Type | Description | Thread Standard |

|---|---|---|

| Threaded Elbow (45° / 90°) | Changes direction of flow | NPT / BSPT / BSPP |

| Threaded Tee | Branches flow into two directions | NPT / BSP |

| Threaded Coupling / Half Coupling | Connects two male threaded pipes | NPT |

| Threaded Plug / Cap | Closes end of threaded pipe | NPT / BSP |

| Threaded Union | Allows disconnection of pipelines | NPT / BSP |

Top Manufacturers of Incoloy 825 Threaded Fittings

These companies specialize in the production of high-quality Incoloy 825 threaded pipe fittings:

| Manufacturer | Country | Capabilities |

|---|---|---|

| Ramesh Steel & Alloys | India | Forged threaded fittings per ASTM B564 |

| Jiangsu Haohua Industry Group | China | Custom Incoloy 825 NPT/BSP fittings with inspection |

| NeoNickel | UK / EU | Precision-machined threaded components |

| Special Metals Corporation | USA | Original alloy developer, OEM-grade components |

| Rajtilak Metal | India | Wide range of Incoloy threaded and socket weld fittings |

Certifications and Quality Standards

Manufacturers follow international testing and inspection protocols to ensure quality and compliance:

| Standard / Certificate | Purpose |

|---|---|

| ASTM B564 | Standard for forged nickel alloy fittings |

| ASME B16.11 | Forged fittings dimension and tolerance |

| EN 10204 3.1 / 3.2 | Mill Test Certificate with chemical/mechanical data |

| PMI Test | Material composition verification |

| ISO 9001 | Quality Management System Certification |

Applications of Incoloy 825 Threaded Fittings

These fittings are used in piping systems where welding is not feasible or allowed due to site or safety conditions:

| Industry | Application |

|---|---|

| Chemical Processing | Acid lines, corrosive fluid control systems |

| Oil & Gas | Offshore skids, chemical injection lines |

| Power Generation | Steam and condensate lines |

| Marine Industry | Seawater handling systems |

FAQs About Incoloy 825 Threaded Fittings Manufacturers

Do manufacturers offer both NPT and BSP thread types?

Yes, most Incoloy 825 fitting manufacturers support both NPT (American) and BSP (British) thread standards upon request.

Can Incoloy 825 fittings be used in high-pressure systems?

Threaded fittings are suitable for low- to medium-pressure applications; for high-pressure use, socket weld or butt weld fittings are preferred.

Are MTC and third-party inspections available?

Reputable manufacturers provide Mill Test Certificates and offer third-party inspections (like SGS or BV) as per customer requirements.