Inconel 600 and Inconel 601 are both nickel-based superalloys known for their excellent high-temperature strength, oxidation resistance, and corrosion resistance. While they share a similar nickel-chromium base, subtle differences in alloying elements make each suited for different industrial applications, including chemical processing, aerospace, power generation, and high-temperature furnaces. Understanding the distinctions between these two alloys ensures optimal material selection for engineering projects.

Chemical Composition Comparison

The composition differences affect mechanical properties, oxidation resistance, and high-temperature performance.

| Alloy | Nickel (Ni) | Chromium (Cr) | Iron (Fe) | Aluminum (Al) | Copper / Other |

|---|---|---|---|---|---|

| Inconel 600 | 72% | 14–17% | 6–10% | Trace | C, Mn, Si trace |

| Inconel 601 | 58–63% | 21–25% | ≤6% | 1–1.5% | C, Mn, Si trace |

Mechanical Properties Comparison

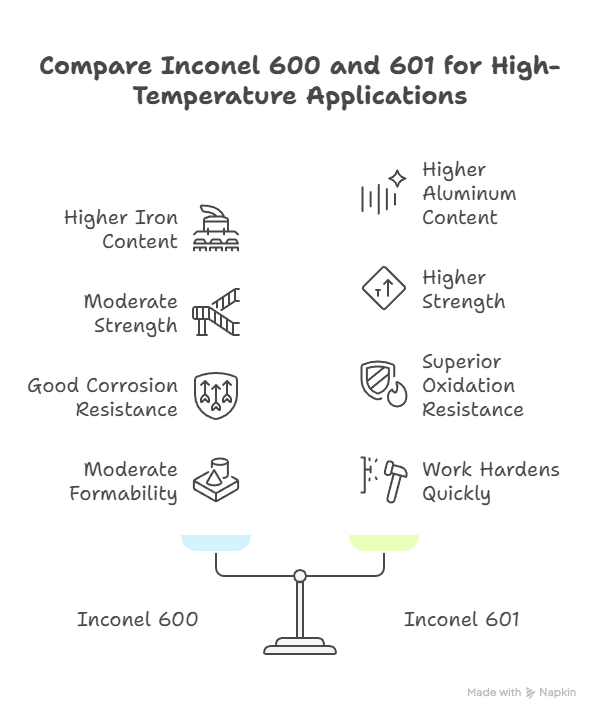

Inconel 601 was developed to improve oxidation resistance at very high temperatures, while Inconel 600 maintains a balance of strength and corrosion resistance.

| Property | Inconel 600 | Inconel 601 |

|---|---|---|

| Yield Strength (MPa) | 138–275 | 205–310 |

| Tensile Strength (MPa) | 275–515 | 515–760 |

| Elongation (%) | 30–40 | 25–40 |

| Hardness (HRB) | 75–95 | 85–95 |

| Service Temperature (°C) | Up to 1100°C | Up to 1200°C |

Corrosion and Oxidation Resistance

Both alloys resist oxidation and corrosion, but Inconel 601 offers superior high-temperature oxidation resistance due to its aluminum content.

| Environment | Inconel 600 | Inconel 601 |

|---|---|---|

| Oxidizing Atmosphere | Excellent | Superior at >1100°C |

| Corrosive / Chemical Media | Good resistance to acids and alkalis | Good resistance, slightly better than 600 at high temperature |

| Marine / Seawater | Moderate resistance | Moderate resistance |

Fabrication and Machinability

Both alloys can be fabricated and welded, but 601 requires some precautions due to work hardening at elevated temperatures.

| Factor | Inconel 600 | Inconel 601 |

|---|---|---|

| Weldability | Good with standard nickel-based filler metals | Good, may require preheating for thick sections |

| Formability | Moderate, hot and cold forming possible | Moderate, work hardens quickly |

| Machinability | Moderate, sharp tools recommended | Moderate, slightly harder than 600 |

Typical Applications

Inconel 600 and 601 are applied in high-temperature, corrosive, or oxidizing environments depending on alloy performance requirements.

| Application Area | Inconel 600 | Inconel 601 |

|---|---|---|

| Furnace Components | Heaters, heat exchangers, furnace parts | High-temperature furnace elements, radiant tubes |

| Chemical Processing | Reactors, piping, exchangers | High-temperature reactors, chemical vessels |

| Aerospace | Moderate stress engine parts | High-temperature oxidation-resistant components |

| Industrial Heating | Heat treatment fixtures | Thermocouple protection tubes, heating elements |

Ncalloys Inconel Supply

Ncalloys supplies both Inconel 600 and 601 in bars, sheets, tubes, wires, and custom machined parts with full certification and quality control.

Manufacturer: Ncalloys

Contact Email: [email protected]

Related Questions

1. Which alloy is better for very high-temperature oxidation?

Inconel 601 is superior due to the addition of aluminum, which forms a protective oxide layer at extreme temperatures.

2. Can both alloys be welded easily?

Yes, both alloys are weldable with nickel-based filler metals, but Inconel 601 may require preheating for thick sections.

3. Which alloy is stronger at high temperatures?

Inconel 601 generally has higher high-temperature strength and better oxidation resistance than Inconel 600, making it suitable for furnace and industrial heating applications.