Inconel 625 pipe price is a common concern for engineers, procurement managers, and project owners who work in extreme environments. As a nickel-chromium-molybdenum alloy, Inconel 625 is designed to perform under high temperature, high pressure, and severe corrosion conditions. Its superior performance directly results in a higher price compared to stainless steel, duplex steel, or standard nickel alloys. Understanding how Inconel 625 pipe pricing is formed helps buyers make better material and sourcing decisions.

What Is the Average Inconel 625 Pipe Price?

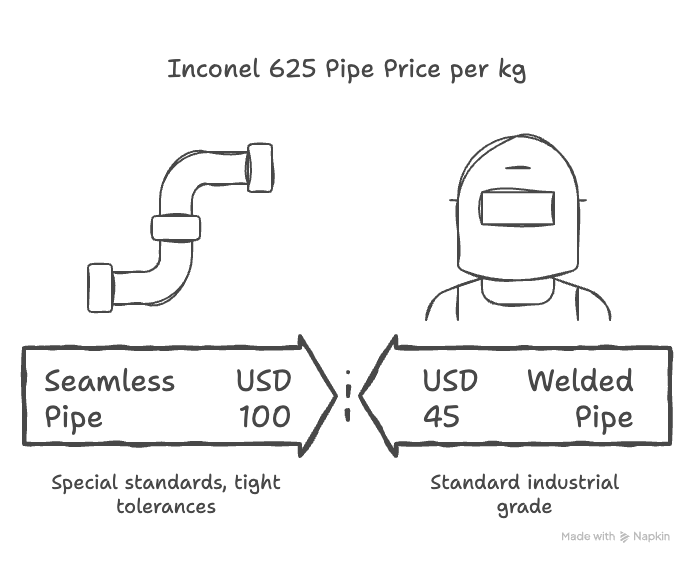

In the international industrial market, Inconel 625 pipe is usually priced by weight rather than by length. The typical price range for standard industrial-grade Inconel 625 pipe is approximately USD 45–85 per kg. For pipes with special standards, tight tolerances, or aerospace certification, the price can exceed USD 100 per kg.

Price differences are normal due to size, wall thickness, manufacturing method, heat treatment condition, and order volume.

Inconel 625 Pipe Price by Manufacturing Method

The production process has a significant impact on the final cost.

Seamless Inconel 625 Pipe: Seamless pipe is produced through hot extrusion or cold drawing. It offers higher pressure resistance, better mechanical uniformity, and improved reliability. Seamless Inconel 625 pipe is widely used in oil & gas, chemical processing, aerospace, and nuclear industries. Due to complex manufacturing and lower yield rate, seamless pipe is more expensive.

Welded Inconel 625 Pipe: Welded pipe is manufactured from Inconel 625 plate or strip. It has a lower cost and shorter delivery time. Welded pipes are suitable for heat exchangers, structural components, and low-to-medium pressure systems. In most cases, welded pipe is 15–30% cheaper than seamless pipe of the same size.

Effect of Pipe Size on Inconel 625 Pipe Price

Pipe dimensions play a key role in pricing.

Outer Diameter: Larger diameters require more raw material and higher forming difficulty, increasing cost.

Wall Thickness: Thicker walls significantly raise weight per meter, directly increasing price.

Length: Fixed-length pipes cost more than random-length pipes due to cutting and inspection requirements.

Small-diameter thin-wall pipes used for instrumentation are generally priced lower per piece but can be higher per kilogram due to precision requirements.

Standards and Specifications That Affect Price

Different standards impose different quality and testing requirements.

ASTM B444 / ASME SB444: The most common standards for Inconel 625 seamless and welded pipe in industrial applications.

AMS Standards: Aerospace-grade pipes with strict chemical composition, mechanical properties, and traceability requirements, resulting in higher pricing.

Custom Specifications: Pipes requiring special chemical limits, non-standard dimensions, or customer-specific testing will increase overall cost.

Heat Treatment and Its Influence on Price

Inconel 625 pipe is commonly supplied in solution annealed condition.

Solution Annealed Pipe: Higher price due to additional heat treatment process, improved corrosion resistance, and better mechanical consistency.

As-Welded or As-Drawn Pipe: Lower price but limited applications.

Heat treatment also affects delivery time, which indirectly impacts procurement cost.

Surface Finish and Processing Cost

Surface condition is another important pricing factor.

Pickled & Annealed: Standard industrial finish with moderate cost.

Bright Annealed: Higher surface quality, used in precision applications, higher price.

Machined or Polished Surface: Additional processing increases unit price.

Raw Material and Nickel Market Impact

Nickel content accounts for a large portion of Inconel 625 pipe cost. Fluctuations in global nickel prices directly affect alloy pipe pricing. In addition, molybdenum and chromium prices also influence overall cost. During periods of nickel price volatility, Inconel 625 pipe prices can change significantly within short timeframes.

Order Quantity and Inconel 625 Pipe Price

Order volume strongly affects unit pricing.

Small Quantity Orders: Higher price per kg due to setup cost, limited production runs, and higher logistics cost.

Bulk Orders: More competitive pricing with lower unit cost and better negotiation space.

Long-term supply contracts often result in more stable pricing.

Inconel 625 Pipe Price by Application

Oil & Gas: Premium pricing due to NDT, pressure testing, and strict quality control.

Chemical Processing: Medium-to-high price depending on corrosion resistance requirements.

Aerospace: Highest price due to certification, traceability, and performance standards.

Marine: Competitive pricing for seawater corrosion resistance and long service life.

Is Inconel 625 Pipe Cost-Effective?

Although the initial purchase price of Inconel 625 pipe is high, it often provides lower total lifecycle cost. Longer service life, reduced maintenance, and fewer replacements make it cost-effective in aggressive environments where material failure would be extremely expensive.

How to Reduce Inconel 625 Pipe Procurement Cost

Choose the Right Grade: Avoid over-specifying standards that exceed application needs.

Optimize Size Selection: Selecting standard sizes reduces custom production cost.

Bulk Purchasing: Larger quantities typically lower unit price.

Supplier Evaluation: Experienced manufacturers can offer better consistency and pricing.

Related Questions

How much does Inconel 625 pipe cost per kg?

In most industrial markets, Inconel 625 pipe is priced between USD 45 and 85 per kg, depending on size, standard, and quantity.

Why is Inconel 625 pipe so expensive?

High nickel content, complex manufacturing processes, strict quality control, and excellent performance in extreme environments drive the higher price.

Is seamless Inconel 625 pipe worth the higher price?

Yes, for high-pressure, high-temperature, or critical applications, seamless pipe provides better reliability and longer service life, justifying the higher cost.