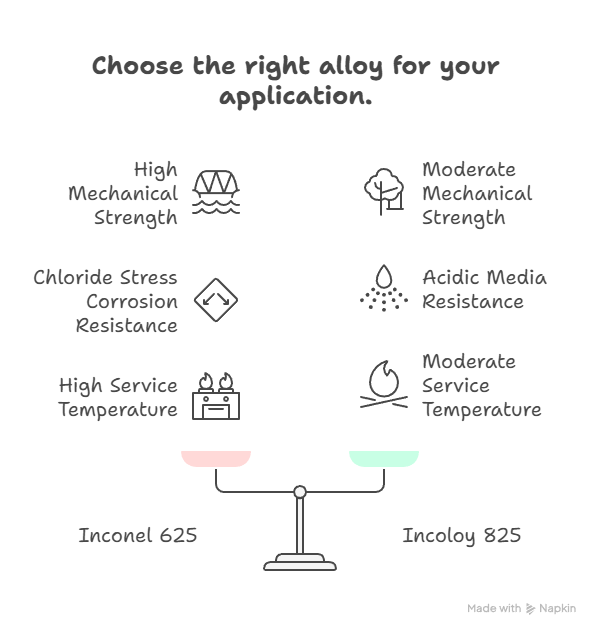

Inconel 625 and Incoloy 825 are two nickel-based alloys designed for extreme corrosion and high-temperature applications. While both provide excellent chemical resistance, their compositions, mechanical properties, and optimal environments differ. Inconel 625 emphasizes high mechanical strength and resistance to chloride stress corrosion, whereas Incoloy 825 is engineered for superior resistance to reducing and oxidizing environments, especially in acidic or chloride-rich conditions. Comparing these alloys helps industries like chemical processing, oil & gas, marine engineering, and power generation select the best material for their specific applications.

Chemical Composition Comparison

The primary difference lies in the alloying elements that target corrosion resistance versus mechanical strength.

| Alloy | Nickel (Ni) | Chromium (Cr) | Molybdenum (Mo) | Iron (Fe) | Copper (Cu) | Other Elements |

|---|---|---|---|---|---|---|

| Inconel 625 | ≥58% | 20–23% | 8–10% | ≤5% | – | Niobium 3.15–4.15%, C trace |

| Incoloy 825 | 38–46% | 19.5–23.5% | 2.5–3.5% | 38–46% | 1–2% | C, Mn, Si trace, Ti, Cu |

Mechanical Properties Comparison

Inconel 625 is stronger mechanically, while Incoloy 825 is optimized for corrosion resistance rather than high-temperature strength.

| Property | Inconel 625 | Incoloy 825 |

|---|---|---|

| Yield Strength (MPa) | 414–552 | 170–275 |

| Tensile Strength (MPa) | 827–965 | 485–690 |

| Elongation (%) | 30–40 | 30–40 |

| Hardness (HRB) | 95–105 | 70–90 |

| Service Temperature (°C) | Up to 980°C continuously | Up to 315°C continuously |

Corrosion Resistance

Both alloys resist corrosion, but Incoloy 825 excels in acidic and reducing environments, whereas Inconel 625 is superior for high-temperature oxidation and chloride stress corrosion.

| Environment | Inconel 625 | Incoloy 825 |

|---|---|---|

| Oxidizing Atmosphere | Excellent up to 980°C | Good at moderate temperatures |

| Chloride Stress Corrosion | Excellent | Good resistance, less than 625 |

| Acidic Media (Sulfuric, Nitric) | Good | Excellent |

| Marine / Seawater | Excellent | Good to moderate |

Fabrication and Welding

Both alloys can be fabricated and welded with appropriate care, but their applications may dictate different processing techniques.

| Factor | Inconel 625 | Incoloy 825 |

|---|---|---|

| Weldability | Excellent, widely used in welded assemblies | Excellent, easily welded with standard nickel-based fillers |

| Formability | Good; may work-harden | Good; more ductile at room temperature |

| Machinability | Moderate; specialized tooling recommended | Moderate; easier than 625 due to lower strength |

Typical Applications

Inconel 625 is chosen for strength and high-temperature corrosion resistance, while Incoloy 825 is preferred for chemical and acidic environments.

| Application Area | Inconel 625 | Incoloy 825 |

|---|---|---|

| Chemical Processing | Acid-resistant piping, heat exchangers, reactors | Sulfuric/nitric acid vessels, chemical piping, evaporators |

| Marine / Offshore | Seawater piping, desalination equipment | Seawater handling less frequent, more acidic solutions |

| Aerospace | Turbine components, exhaust systems | Limited use; mainly corrosion-exposed parts |

| Power Generation | Boiler tubes, heat exchangers | Cooling system components with acidic exposure |

| Oil & Gas | High-strength piping, valves | Acid gas processing, chemical injection lines |

Ncalloys Alloy Supply

Ncalloys supplies both Inconel 625 and Incoloy 825 in bars, sheets, tubes, wires, and custom machined parts with full quality certification.

Manufacturer: Ncalloys

Contact Email: [email protected]

Related Questions

1. Which alloy is stronger, Inconel 625 or Incoloy 825?

Inconel 625 is mechanically stronger with higher tensile and yield strength, especially at elevated temperatures.

2. Which alloy is better for acidic chemical environments?

Incoloy 825 offers superior resistance to acids and reducing environments, making it ideal for chemical processing applications.

3. Can both alloys be welded easily?

Yes, both alloys are weldable with nickel-based filler metals, but Incoloy 825 is slightly easier to weld due to its lower strength and higher ductility.