Inconel 718 is a high-strength, corrosion-resistant nickel-chromium alloy often used in aerospace, nuclear, oil & gas, and high-performance automotive industries. It offers excellent weldability, fatigue resistance, and creep strength at temperatures up to 1300°F (704°C). Because of its specialized nature and reliance on raw nickel pricing, Inconel 718 can be significantly more expensive than standard stainless steels or other nickel alloys. This article explores Inconel 718 prices by form, influencing factors, and sizing data.

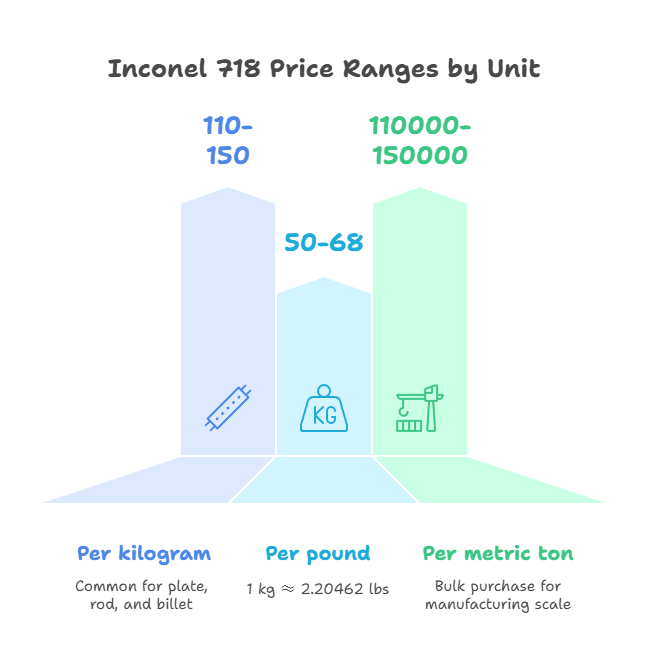

Inconel 718 Price per Unit (kg, lb, ton)

The cost of Inconel 718 varies based on form (bar, plate, tubing, sheet, wire), country of origin, certifications, and order volume. Below is a table showing the typical price range in 2025:

| Unit | Price Range (USD) | Notes |

|---|---|---|

| Per kilogram | $110 – $150 | Common for plate, rod, and billet |

| Per pound | $50 – $68 | 1 kg ≈ 2.20462 lbs |

| Per metric ton | $110,000 – $150,000 | Bulk purchase for manufacturing scale |

Price Comparison by Product Form

Different shapes and processing affect pricing. Below is a breakdown of Inconel 718 pricing by form:

| Form | Typical Sizes | Price per kg (USD) |

|---|---|---|

| Rod / Bar | Ø 12mm – 150mm | $110 – $130 |

| Plate | Thickness 6mm – 50mm | $115 – $140 |

| Tube / Pipe | 1/4″ OD – 4″ OD | $120 – $145 |

| Sheet / Strip | 0.5mm – 3mm thick | $125 – $150 |

| Wire | Ø 0.5mm – 3mm | $130 – $155 |

Factors Influencing Inconel 718 Price

Several variables affect the final price of Inconel 718 materials:

• Nickel Content: Inconel 718 contains over 50% nickel; its price tracks closely with global nickel markets.

• Certification: Materials certified to aerospace standards (AMS 5662, AMS 5663) or NACE are more expensive.

• Form Complexity: Cold-drawn tube and wire are pricier than hot-rolled bars or plates.

• Country of Origin: U.S. or EU origin is costlier than Indian or Chinese mills due to QA standards and compliance (e.g. DFARS).

• MOQ and Lead Time: Small-quantity orders or urgent production typically carry premiums.

• Finish and Processing: Centerless ground bars, precision machining, or vacuum melting increase price.

Inconel 718 Major Suppliers and Mills

Some of the world’s major Inconel 718 producers and distributors include:

| Supplier | Region | Common Certifications |

|---|---|---|

| Special Metals (PCC) | USA | AMS 5662, ASTM B637 |

| VDM Metals | Germany | EN 10204 3.1, ISO 9001 |

| Haynes International | USA | AMS, ASTM, NACE |

| NeoNickel | UK/EU | PED, AMS, ISO |

| Magellan Metals | USA | AMS 5596, ASTM B670 |

Tips for Buying Inconel 718 at Competitive Prices

• Request mill test certificates (MTCs) to verify alloy compliance

• Compare quotes from multiple suppliers, including international ones

• Consider buying remnant stock for small-quantity needs

• Ask for price breakdowns (material vs. processing)

• For aerospace or critical use, confirm DFARS compliance

Related Questions

How much does Inconel 718 cost per pound?

As of 2025, the price per pound of Inconel 718 ranges from $50 to $68 depending on form, size, and certifications.

Is Inconel 718 more expensive than stainless steel?

Yes, Inconel 718 is significantly more expensive—about 5–10 times more than 316L stainless steel—due to its high nickel content and performance characteristics.

Where can I buy certified Inconel 718 for aerospace use?

Suppliers like Special Metals, Haynes, and NeoNickel provide aerospace-grade Inconel 718 certified to AMS 5662/5663, typically used in jet engines and turbine components.