Inconel 718 springs are specialized components made from the nickel-chromium alloy Inconel 718, renowned for its exceptional mechanical strength, corrosion resistance, and ability to retain performance at elevated temperatures. These springs are widely used in aerospace, automotive, power generation, and chemical processing industries where conventional spring materials fail under extreme conditions. This article explores the properties, design considerations, manufacturing, and applications of Inconel 718 springs.

Chemical Composition

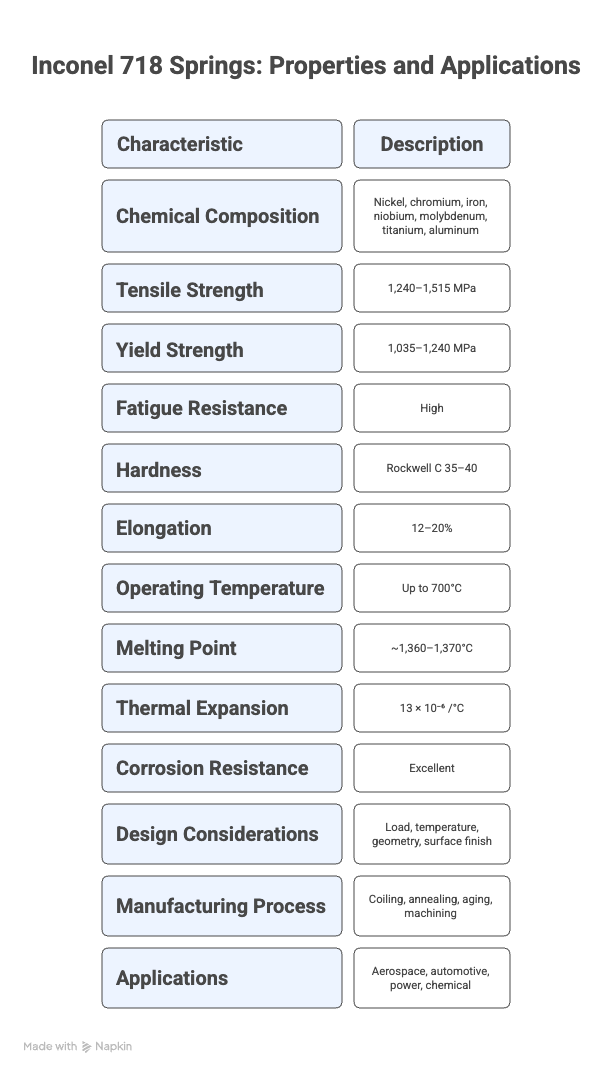

Inconel 718 is composed primarily of nickel (50–55%), chromium (17–21%), iron (balance), niobium (4.75–5.5%), molybdenum (2.8–3.3%), titanium (0.65–1.15%), and aluminum (0.2–0.8%). This unique composition provides a combination of high strength, corrosion resistance, and thermal stability, which is critical for springs operating under repeated stress and high-temperature conditions.

Mechanical Properties

Inconel 718 springs exhibit exceptional mechanical properties:

- Tensile Strength: 1,240–1,515 MPa, ensuring the spring can withstand significant loads without permanent deformation.

- Yield Strength: 1,035–1,240 MPa, offering excellent resistance to creep and stress relaxation.

- Fatigue Resistance: High resistance to cyclic loading, critical for springs subjected to repeated compression and tension.

- Hardness: Rockwell C 35–40, providing good wear resistance for long-term durability.

- Elongation: 12–20%, allowing for sufficient flexibility while maintaining high strength.

Thermal Properties

Inconel 718 springs maintain their properties across a wide temperature range:

- Operating Temperature: Up to 700°C without significant loss of strength or creep resistance.

- Melting Point: ~1,360–1,370°C.

- Coefficient of Thermal Expansion: 13 × 10⁻⁶ /°C, providing predictable dimensional stability during thermal cycling.

Corrosion Resistance

These springs offer excellent resistance to oxidation, corrosion, and stress corrosion cracking, making them suitable for marine, chemical, and high-humidity environments. The chromium content forms a protective oxide layer, preventing degradation in aggressive atmospheres.

Design Considerations

Designing Inconel 718 springs requires careful attention to material properties and application requirements:

- Load Requirements: Ensure the spring can handle both static and dynamic loads without permanent deformation.

- Temperature Effects: Consider the operating temperature, as Inconel 718 retains strength at high temperatures but may creep under continuous load.

- Spring Geometry: Coil diameter, wire thickness, and pitch must be optimized for maximum fatigue life and stress distribution.

- Surface Finish: Smooth surfaces improve fatigue life and reduce the risk of crack initiation.

Manufacturing Process

Inconel 718 springs are typically manufactured through cold or hot coiling, followed by solution annealing and aging treatments to achieve the desired mechanical properties. Heat treatment is essential to precipitate strengthening phases such as gamma prime (γ’) and gamma double prime (γ”), which provide high tensile and yield strength. Precision machining and surface finishing are often employed to meet exacting aerospace and industrial standards.

Applications

Inconel 718 springs are used in demanding environments where conventional spring materials fail:

- Aerospace: Engine components, actuators, landing gear, and vibration dampening systems.

- Automotive: High-performance exhaust systems and turbocharger mechanisms.

- Power Generation: Gas turbine engines, valves, and high-temperature control systems.

- Chemical Processing: Pumps, reactors, and high-temperature valves exposed to corrosive media.

Related Questions

What makes Inconel 718 springs suitable for high temperatures? They retain high tensile and yield strength up to 700°C and resist creep, ensuring reliable performance in extreme environments.

Can Inconel 718 springs resist corrosion? Yes, they have excellent corrosion and oxidation resistance due to their high chromium and nickel content.

Where are Inconel 718 springs commonly used? They are widely used in aerospace, automotive, power generation, and chemical processing applications that require high strength and durability under extreme conditions.