Inconel, Hastelloy, and Monel are high-performance nickel-based alloys used across critical industries like aerospace, petrochemical, marine, and power generation. Due to their high alloy content and stringent quality requirements, global sourcing of these materials demands careful supplier selection, specification verification, and import planning. This article explores the global sourcing landscape for Inconel, Hastelloy, and Monel, highlighting top-producing countries, supplier networks, certifications, and logistics strategies.

Global Supplier Regions for Inconel, Hastelloy, and Monel

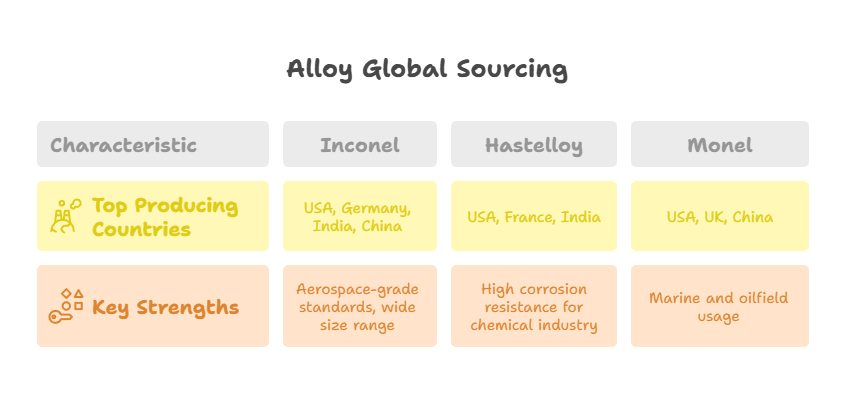

Different countries specialize in the production of these superalloys based on their metallurgical capabilities and export infrastructure:

| Alloy | Top Producing Countries | Key Strengths |

|---|---|---|

| Inconel | USA, Germany, India, China | Aerospace-grade standards, wide size range, bar/plate/tube availability |

| Hastelloy | USA, France, India | High corrosion resistance for chemical industry, specialty grades like C-22, C-276 |

| Monel | USA, UK, China | Marine and oilfield usage, resistance to seawater and acids |

Major Manufacturers and Exporters

The table below lists some of the globally recognized producers and exporters of Inconel, Hastelloy, and Monel:

| Company | Location | Alloy Brands | Certifications |

|---|---|---|---|

| Special Metals (PCC) | USA | Inconel, Monel | AMS, ASTM, ISO 9001, NORSOK |

| Haynes International | USA | Hastelloy, Inconel | ASME, NACE, EN 10204 |

| VDM Metals | Germany | Inconel, Hastelloy | PED, ISO 14001, EN standards |

| NeoNickel | UK/EU | Inconel, Monel, Hastelloy | AMS, ISO, CE |

| Jindal Stainless/Nickel Alloys | India | Inconel, Hastelloy | ASTM, ISO 9001, PED |

Common Forms and Sizing in International Trade

Nickel alloys are typically traded globally in standardized forms for ease of logistics and handling:

| Form | Typical Size Range | Common Alloys Available |

|---|---|---|

| Bar / Rod | 6mm – 200mm dia | Inconel 625, 718; Hastelloy C276; Monel 400 |

| Plate / Sheet | 0.5mm – 100mm thick | All grades |

| Tubing / Pipe | OD 6mm – 100mm | Inconel 600, 625; Monel K500; Hastelloy C22 |

| Wire / Strip | 0.1mm – 3mm | Inconel 600; Hastelloy B2; Monel 400 |

Key Considerations When Sourcing Globally

• DFARS Compliance: If sourcing for aerospace/defense, ensure the supplier is DFARS-compliant.

• Mill Test Certificates (MTCs): Always request 3.1 or 3.2 MTCs for traceability and composition verification.

• Incoterms: Understand trade terms such as FOB, CIF, DDP, etc., when importing.

• Shipping Lead Time: Air freight is faster (7–10 days), sea freight is cheaper (3–6 weeks).

• Customs Duties: Some countries impose high tariffs on nickel alloys. Use HS Code 7505 for customs classification.

Logistics and Import Tips

• Partner with a freight forwarder experienced in metals to handle documentation and customs.

• For large-volume orders, ask about bulk discounts and bundled shipping.

• Ensure alloys are packaged rust-free with proper identification (heat number, grade, batch).

Related Questions

Which countries are the largest exporters of Inconel, Hastelloy, and Monel?

The USA, Germany, and India are leading exporters of these nickel alloys, with mills like Special Metals, VDM Metals, and Jindal among the top sources.

What documents should I request when sourcing these alloys internationally?

Ask for mill test certificates (EN 10204 3.1 or 3.2), chemical composition reports, and any relevant compliance certificates such as PED, NACE, or ISO.

Are there minimum order quantities (MOQ) for global sourcing of nickel alloys?

Yes, most mills have MOQs ranging from 50 kg to 500 kg depending on the form. Distributors may offer smaller quantities but at higher prices.