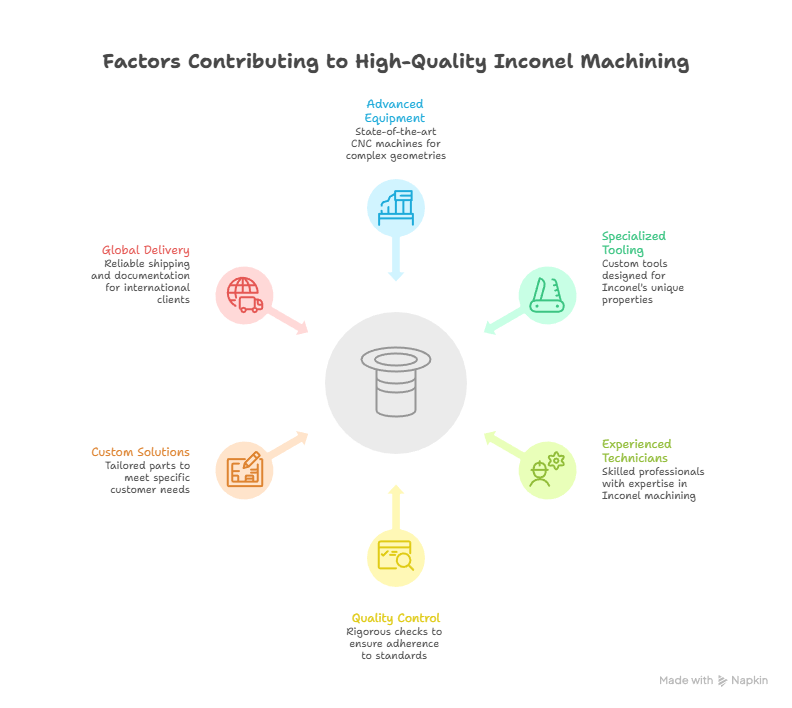

Inconel machined parts manufacturers specialize in producing precision components from Inconel alloys for aerospace, oil and gas, chemical, power generation, and high-performance industrial applications. Due to the unique properties of Inconel — including exceptional high-temperature strength, corrosion resistance, and oxidation resistance — machining these alloys requires advanced equipment, specialized tooling, and experienced technicians. Ncalloys is a trusted manufacturer of Inconel machined parts, offering quality control, custom solutions, and global delivery support.

About Ncalloys Inconel Machined Parts

Ncalloys manufactures high-precision Inconel components with strict adherence to customer specifications and international standards. Our machining facilities are equipped with CNC milling, turning, grinding, and multi-axis machining centers to handle complex geometries with excellent surface finish and tight tolerances.

Manufacturer: Ncalloys

Contact Email: [email protected]

Common Inconel Alloys Machined

The choice of Inconel alloy depends on the application’s temperature, strength, and corrosion requirements.

| Inconel Alloy | Key Characteristics | Typical Use |

|---|---|---|

| Inconel 625 | High corrosion resistance, good weldability | Marine parts, chemical valves, heat exchangers |

| Inconel 718 | Very high strength, precipitation-hardened | Aerospace fasteners, turbine components |

| Inconel 600 | Balanced oxidation and corrosion resistance | Furnace components, heat treatment fixtures |

| Inconel X-750 | High temperature creep resistance | Springs, blades, rocket components |

Types of Machined Parts Produced

Ncalloys produces a wide range of Inconel machined parts to meet diverse industry demands.

| Part Type | Application |

|---|---|

| Threads & Fasteners | High-temperature screws, bolts, nuts |

| Shafts & Spindles | Rotating components in harsh environments |

| Valves & Fittings | Corrosion-resistant fluid control systems |

| Flanges & Rings | Pressure vessel and piping systems |

| Custom Precision Parts | Application-specific components with tight tolerances |

Capabilities of an Inconel Machining Manufacturer

Precision machining of Inconel requires specialized processes due to work hardening and tool wear.

| Capability | Description |

|---|---|

| CNC Turning | High-precision cylindrical components |

| CNC Milling | Complex 3D features and surfaces |

| Grinding & Polishing | Fine finishes and tight tolerances |

| Multi-Axis Machining | Parts with intricate geometries |

| Tooling & Fixturing | Custom fixtures for stable machining |

Industries Served

The unique properties of Inconel make machined parts indispensable in high-performance sectors.

| Industry | Application Examples |

|---|---|

| Aerospace | Turbine components, engine parts |

| Oil & Gas | Downhole tools, valves, connectors |

| Chemical Processing | Severe corrosive service parts |

| Power Generation | Heat-resistant structural components |

| Marine Engineering | Saltwater equipment, fasteners |

Quality Standards and Certification

Ncalloys ensures that all Inconel machined parts meet international quality requirements and certification standards.

| Standard | Purpose |

|---|---|

| ISO 9001 | Quality management system compliance |

| AS9100 | Aerospace quality standards |

| Material Test Reports (MTR) | Full chemical and mechanical traceability |

| Third-Party Inspection | Optional detailed inspection and approval |

Why Choose Ncalloys

Ncalloys delivers high-precision Inconel machined components with reliable consistency, advanced manufacturing technology, and responsive customer support.

| Advantage | Benefit |

|---|---|

| Experienced Machinists | High accuracy and surface finish |

| Advanced Equipment | Supports complex and high-tolerance parts |

| Technical Guidance | Material and process support |

| Global Shipping | Reliable delivery and documentation |

Related Questions

1. What Inconel alloys are commonly machined?

Inconel 625, 718, 600, and X-750 are commonly machined for high-performance components.

2. Why is machining Inconel challenging?

Inconel work hardens rapidly and is abrasive on cutting tools, requiring specialized tooling and optimized machining strategies.

3. How can I order Inconel machined parts from Ncalloys?

You can contact Ncalloys by email at [email protected] to request quotes, discuss specifications, and receive technical support.