Inconel is a high-performance nickel-chromium alloy known for its exceptional strength, corrosion resistance, and high-temperature stability. It is widely used in aerospace, chemical processing, marine, and nuclear industries. Choosing the right Inconel manufacturer is critical for ensuring material quality, technical support, and cost efficiency. This article outlines the top Inconel manufacturers, types of products they offer, and how to evaluate and choose the best supplier for your needs.

Top Inconel Manufacturers Globally

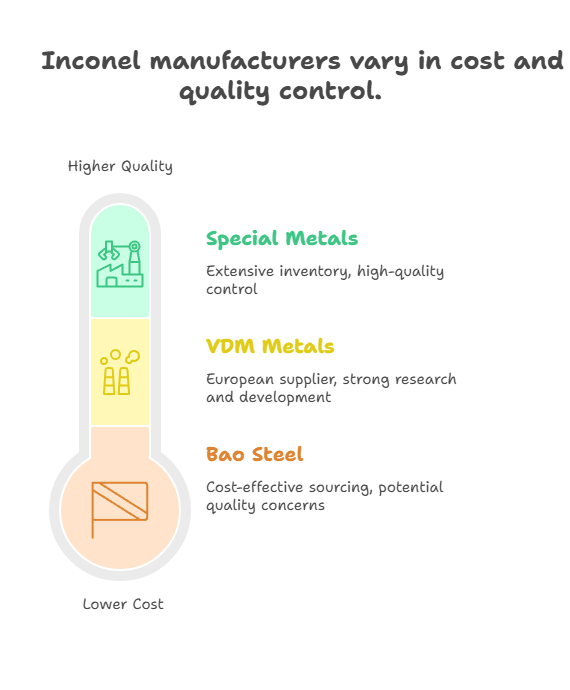

The following companies are recognized as global leaders in producing Inconel alloys such as Inconel 600, 625, 718, and X-750.

| Manufacturer | Country | Key Inconel Alloys | Specialization |

|---|---|---|---|

| Special Metals (a PCC Company) | USA | 600, 625, 718, X-750 | Original developer of Inconel, extensive inventory |

| VDM Metals | Germany | 600, 601, 625 | European supplier, strong R&D and mill capacity |

| Alleima (formerly Sandvik) | Sweden | 625, 825 | Seamless tubes and wire |

| Haynes International | USA | 625, 718, 725 | Flat products, strip, and aerospace alloys |

| Bao Steel | China | 600, 625, 800 series | Mass production, cost-effective sourcing |

Types of Inconel Products Offered by Manufacturers

Depending on your project, you’ll need specific product forms. Here’s a summary of the Inconel products typically manufactured:

| Product Form | Available Grades | Applications |

|---|---|---|

| Plate & Sheet | 600, 625, 718 | Aircraft engines, exhaust systems, chemical tanks |

| Bar & Rod | 625, 718 | Machined parts, shafts, bolts |

| Tube & Pipe | 625, 601, 825 | Heat exchangers, marine equipment |

| Wire | 600, 625, X-750 | Springs, heating elements, welding |

| Forgings | 718, 725 | Jet engines, oil tools |

How to Choose a Reliable Inconel Manufacturer

Choosing the right manufacturer is essential to ensure consistent quality, delivery timelines, and compliance with international standards:

• Look for ISO 9001, AS9100, or NORSOK certifications

• Confirm compliance with ASTM, AMS, or EN standards for Inconel grades

• Evaluate their heat treatment and melting capabilities (e.g., VIM, ESR, VAR)

• Ask about mill test certificates (MTCs) and lot traceability

• Consider delivery times, especially for aerospace or defense applications

• Check if they offer custom sizes or cut-to-length services

Inconel Manufacturer Selection: Domestic vs. International

There are advantages and trade-offs when selecting between local and global manufacturers:

| Type | Advantages | Limitations |

|---|---|---|

| Domestic (USA/EU) | Faster shipping, high-quality control, support | Higher prices, limited stock on rare grades |

| International (China/India) | Lower cost, mass availability | Longer lead time, potential quality concerns |

Which Inconel Grade Should You Request from the Manufacturer?

Each Inconel alloy has unique performance characteristics. Choosing the right one depends on the application:

| Grade | Key Features | Application |

|---|---|---|

| Inconel 600 | Oxidation resistance, moderate strength | Furnace components, nuclear reactors |

| Inconel 625 | Excellent corrosion & fatigue resistance | Marine, chemical plants, aerospace |

| Inconel 718 | High strength, weldable, cryogenic capable | Jet engines, turbines, automotive tooling |

| Inconel X-750 | Precipitation-hardened, spring-resistant | Springs, nuclear reactors, heat-treated parts |

Related Questions

Who are the top Inconel manufacturers?

Special Metals (USA), VDM Metals (Germany), Haynes International (USA), Bao Steel (China), and Alleima (Sweden) are some of the leading Inconel manufacturers globally.

What is the most commonly used Inconel grade?

Inconel 625 is the most versatile and widely used grade due to its outstanding corrosion resistance, weldability, and high-temperature strength.

How can I verify the quality of Inconel from a manufacturer?

Request material test certificates (MTCs), ensure compliance with ASTM/AMS standards, and verify certifications like ISO 9001 or AS9100 for aerospace applications.