Inconel, a family of austenitic nickel-chromium-based superalloys, is widely used in extreme environments due to its exceptional resistance to heat, corrosion, and oxidation. Understanding the pricing structure of Inconel is crucial for industries such as aerospace, chemical processing, and marine engineering, as it directly influences manufacturing and procurement costs. This article provides an in-depth analysis of Inconel metal prices, exploring various factors that determine its cost, price trends across different grades, comparison with similar alloys, and geographic price variations.

What Is Inconel and Why Is It Expensive?

Inconel is a trademarked name for a family of nickel-chromium-based alloys primarily produced by Special Metals Corporation. Common grades include Inconel 600, 625, 718, and X-750, each tailored for specific high-temperature or corrosive applications. The high nickel content (ranging from 50% to over 70%) contributes significantly to its price, as nickel is a costly base metal. Additionally, the complex production process and demand in specialized industries increase the overall cost.

Factors Influencing Inconel Metal Price

Inconel pricing is influenced by multiple factors including:

1. Raw Material Cost: Nickel and chromium prices directly impact Inconel’s cost.

2. Manufacturing Complexity: Advanced smelting, alloying, and forging processes raise production expenses.

3. Grade & Specification: Different grades have different alloying elements, affecting the cost per kg or lb.

4. Market Demand: Demand from aerospace, nuclear, and chemical sectors can cause price surges.

5. Regional Availability: Geographic location and availability of suppliers play a role in final pricing.

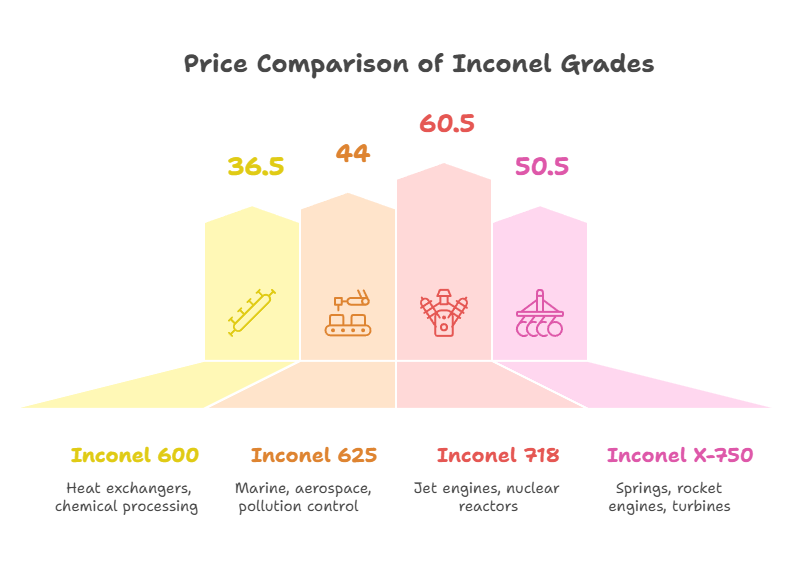

Average Price of Inconel by Grade

The table below compares the average price ranges of commonly used Inconel grades as of recent data.

| Inconel Grade | Price Per Pound (USD) | Price Per Kilogram (USD) | Main Applications |

|---|---|---|---|

| Inconel 600 | $15 – $18 | $33 – $40 | Heat exchangers, chemical processing |

| Inconel 625 | $18 – $22 | $40 – $48 | Marine, aerospace, pollution control |

| Inconel 718 | $25 – $30 | $55 – $66 | Jet engines, nuclear reactors |

| Inconel X-750 | $20 – $26 | $44 – $57 | Springs, rocket engines, turbines |

Inconel vs Stainless Steel Price Comparison

Inconel is significantly more expensive than stainless steel due to its superior mechanical and thermal properties. Below is a comparison for reference:

| Metal Type | Price Per Pound (USD) | Key Feature |

|---|---|---|

| Inconel 625 | $20 | High corrosion resistance, 1000°C+ strength |

| 316 Stainless Steel | $2.50 – $3 | Corrosion resistant, lower temperature use |

Global Price Variations

Inconel prices also vary depending on the region due to import taxes, logistics, and local market conditions. The following table highlights average regional differences:

| Region | Average Price Per Kg (USD) | Notes |

|---|---|---|

| United States | $45 – $60 | Domestic production, high demand in aerospace |

| Europe | $50 – $65 | Higher energy and compliance costs |

| China | $40 – $55 | Competitive pricing, growing production |

| India | $35 – $50 | Lower manufacturing costs, export focus |

Forecast and Market Trends

Inconel prices have shown an upward trend due to increasing demand in the aerospace and energy sectors, as well as volatility in nickel prices. Many manufacturers are now facing tighter margins, prompting long-term supply agreements or stockpiling strategies.

Buying Tips for Inconel Alloys

To optimize cost when purchasing Inconel:

1. Buy in bulk: Larger orders may qualify for volume discounts.

2. Source regionally: Avoid import duties by buying domestically if possible.

3. Confirm specification: Ensure correct grade to avoid overpaying for unnecessary properties.

4. Check scrap availability: Recycled Inconel can sometimes be significantly cheaper while still performing well for non-critical uses.

FAQs Related to Inconel Metal Price

What is the current price of Inconel per kg?

Depending on the grade, Inconel prices typically range from $33 to $66 per kilogram.

Why is Inconel more expensive than stainless steel?

Inconel contains a higher percentage of nickel and chromium, both costly materials, and undergoes a more complex manufacturing process, making it more expensive than stainless steel.

Which Inconel grade is the most cost-effective?

Inconel 600 is generally the most affordable among commonly used grades, offering good corrosion resistance and high-temperature performance at a lower cost than 625 or 718.