Inconel is a high-performance superalloy known for its strength, heat resistance, and corrosion resistance. It is commonly used in aerospace, nuclear, marine, and chemical processing industries. The price of Inconel per pound varies depending on the specific alloy grade, market conditions, product form, and whether the material is new or scrap. This article provides a detailed breakdown of current Inconel pricing per pound for both virgin material and scrap, and highlights the key factors affecting these prices.

Average Inconel Price Per Pound by Grade

Different Inconel grades have different compositions, which impacts their cost. The following table shows average price ranges for the most commonly used Inconel alloys:

| Inconel Grade | Price Per Pound (USD) | Typical Applications |

|---|---|---|

| Inconel 600 | $15 – $18 | Heat exchangers, furnaces |

| Inconel 625 | $18 – $25 | Marine hardware, chemical plant piping |

| Inconel 718 | $25 – $35 | Jet engines, nuclear power systems |

| Inconel X-750 | $22 – $30 | Rocket engines, turbine blades |

Scrap Inconel Price Per Pound

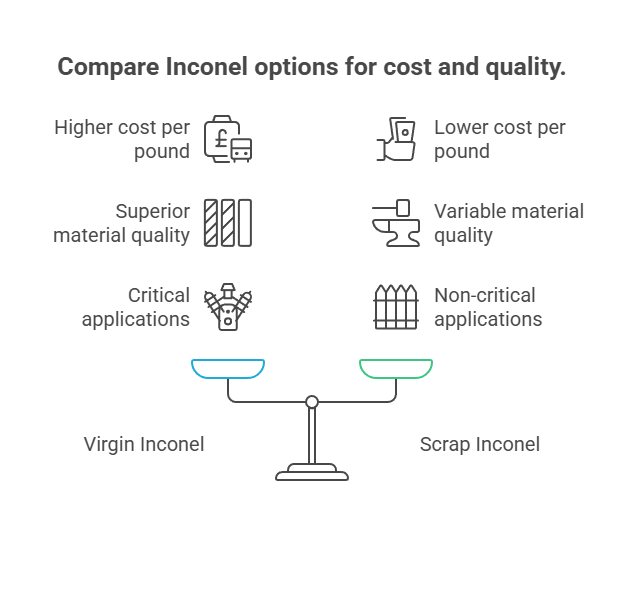

Scrap Inconel is significantly cheaper than virgin material and is usually sold to recyclers based on nickel content. The price varies depending on alloy type, condition, and regional market rates.

| Scrap Type | Price Per Pound (USD) | Notes |

|---|---|---|

| Mixed Inconel Scrap | $0.70 – $1.50 | Unsorted, lower purity |

| Inconel 625 Scrap | $2.50 – $3.20 | High nickel content |

| Inconel 718 Scrap | $1.80 – $2.50 | High-strength alloy, moderately valuable |

Factors Affecting Inconel Price Per Pound

1. Alloy Composition: The higher the content of nickel, molybdenum, and other expensive elements, the higher the price.

2. Product Form: Bar stock, sheet, tubing, and wire all have different processing costs, which influence the per-pound price.

3. Processing Method: Hot-rolled or cold-drawn Inconel usually costs more due to the additional steps involved.

4. Market Demand: Increased demand from aerospace and energy industries can drive up prices.

5. Geographic Region: Prices vary by country and supplier, affected by import/export costs, local taxes, and availability.

How to Estimate Total Cost Based on Price Per Pound

To calculate the total material cost for a project, use the formula below:

Total Cost = Weight (lb) × Price per Pound

For example, if you need 100 pounds of Inconel 625 at $22 per pound, the total cost is 100 × 22 = $2,200.

Tips for Buying Inconel at Competitive Prices

1. Compare Suppliers: Request quotes from multiple vendors to find the best deal.

2. Buy in Bulk: Large quantity orders often qualify for discounted pricing.

3. Consider Scrap: For non-critical components, scrap Inconel may offer cost savings.

4. Lock in Pricing: If prices are volatile, negotiate long-term contracts to secure fixed rates.

FAQs About Inconel Price Per Pound

What is the average price of Inconel per pound?

The average price of Inconel ranges from $15 to $35 per pound for virgin material, depending on the grade and product form.

Why is Inconel more expensive than stainless steel?

Inconel contains a high percentage of nickel and other costly alloying elements, and requires complex manufacturing processes, making it more expensive than stainless steel.

Can I use scrap Inconel instead of new material?

Yes, scrap Inconel can be used in some applications, especially where material certification and mechanical performance are less critical. It offers a cost-effective alternative.