Inconel wire is a high-performance nickel-chromium alloy wire used in industries requiring excellent corrosion resistance, oxidation resistance, and high-temperature strength. Selecting a reliable Inconel wire manufacturer is critical for ensuring consistent quality, precise dimensions, and compliance with industrial standards. Inconel wires are widely used in heating elements, aerospace components, chemical processing, and marine applications.

Key Features of Inconel Wire

Understanding the key features helps in choosing the right wire for specific applications.

| Feature | Description |

|---|---|

| Corrosion Resistance | Excellent resistance to seawater, acids, and oxidizing environments |

| High-Temperature Stability | Maintains mechanical strength and oxidation resistance up to 1100°C depending on alloy grade |

| Mechanical Strength | High tensile and fatigue strength, especially Inconel 718 |

| Workability | Can be drawn into precise diameters, though machining is challenging |

Common Inconel Wire Alloys

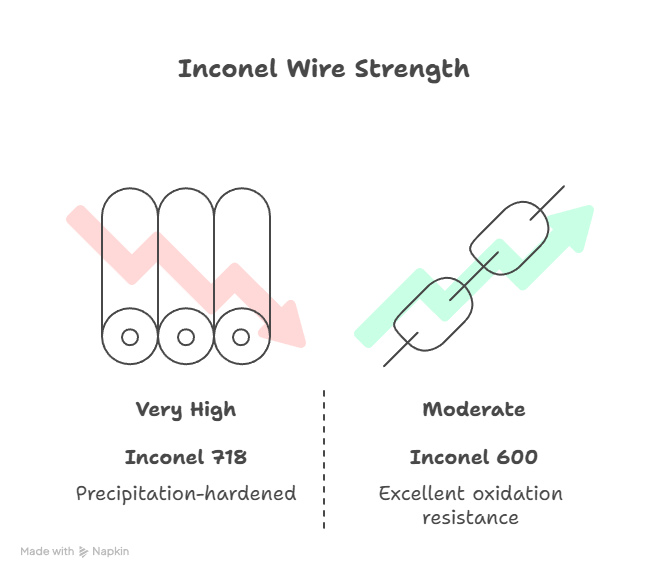

Different grades are used depending on temperature and strength requirements.

| Alloy | Properties | Typical Use |

|---|---|---|

| Inconel 600 | Excellent oxidation resistance, moderate strength | Heating elements, thermocouples |

| Inconel 625 | Superior corrosion resistance, good high-temperature strength | Marine equipment, chemical tanks |

| Inconel 718 | Very high strength, precipitation-hardened | Aerospace fasteners, turbine components |

Applications of Inconel Wire

Inconel wire is widely used in industries where high temperature, corrosion, and stress resistance are required.

| Industry | Application |

|---|---|

| Aerospace | Heating elements, turbine components, fasteners |

| Marine | Corrosion-resistant wiring for pumps, valves, and sensors |

| Chemical Processing | Heating coils, thermocouples, process instrumentation |

| Power Generation | High-temperature heaters and resistance elements |

Choosing an Inconel Wire Manufacturer

When selecting a manufacturer, consider the following criteria:

| Factor | Importance |

|---|---|

| Quality Standards | ISO, ASTM compliance, material certificates |

| Wire Diameter Precision | Critical for electrical and heating applications |

| Customization Options | Ability to supply coils, spools, or straightened wire |

| Delivery & Support | On-time supply and technical support |

Related Questions

1. What industries use Inconel wire?

Inconel wire is used in aerospace, marine, chemical processing, power generation, and high-temperature industrial applications.

2. How is Inconel wire different from stainless steel wire?

Inconel wire offers higher temperature resistance, superior corrosion resistance, and better mechanical strength at elevated temperatures compared to stainless steel wire.

3. What should I look for in an Inconel wire manufacturer?

Look for ISO/ASTM certified manufacturers, precise wire diameter capabilities, experience with custom orders, and reliable delivery and technical support.